Stainless steel investment casting creates precise metal parts by pouring molten stainless steel into ceramic molds formed around wax patterns. This ancient technique, also called lost-wax casting, produces components with complex shapes and exceptional surface finishes that would be impossible or extremely expensive to make through machining.

This method particularly excels with stainless steel alloys because it handles their high melting temperatures (around 1500°C) while preserving the material’s corrosion resistance and strength. Parts come out with tolerances as tight as ±0.005 inches and surface finishes around 125 micro-inches, often eliminating the need for additional machining.

Workers inject molten wax into precision-machined metal dies to create exact duplicates of the final part. Each wax pattern includes all the intricate details, geometries, and features of the finished component.

Modern facilities also use 3D printing to create patterns for complex designs or low-volume production runs. Soluble wax or ceramic cores can be inserted to form internal features like holes or cavities.

Multiple wax patterns attach to a central wax sprue using heated tools, creating a “tree” structure. This assembly allows dozens of parts to be cast simultaneously in one batch.

The sprue and connecting runners create pathways for molten metal to flow into each part cavity during pouring. Careful positioning ensures optimal metal flow and minimizes defects.

The wax tree gets repeatedly dipped into ceramic slurry and coated with refractory sand or “stucco.” Each layer must dry completely before applying the next coat.

The first coat uses ultra-fine particles to capture intricate surface details. Subsequent layers use progressively coarser materials for strength, building up a shell thickness of 5-15mm over 5-10 coating cycles.

The ceramic-coated assembly goes into an autoclave or furnace where steam or heat melts out the wax. The wax flows out through the sprue openings, leaving a hollow ceramic mold.

This step requires careful temperature control to prevent the expanding wax from cracking the ceramic shell. Most facilities recover and recycle the melted wax for future use.

Empty ceramic shells fire at 870-1095°C to burn off residual wax and strengthen the ceramic material through sintering. This high-temperature treatment ensures the mold can withstand the thermal shock of molten metal.

Just before pouring, the molds get preheated to improve metal flow and reduce rapid cooling that could cause defects.

Stainless steel melts in induction or arc furnaces to reach pouring temperatures around 1500°C or higher. The preheated ceramic shells sit upright, often supported in sand beds.

Molten metal pours through the sprue opening, filling all cavities through gravity flow. Some operations use vacuum or centrifugal assistance for thin-walled sections.

The poured metal cools and solidifies inside the ceramic molds at controlled rates. Proper cooling prevents defects and ensures dimensional accuracy.

Once solid, the metal forms a complete tree of stainless steel castings connected by the solidified sprue and runners.

Mechanical vibration, hammering, or water-jet blasting breaks away the ceramic shell to expose the metal castings. Chemical leaching may help remove ceramic from hard-to-reach areas.

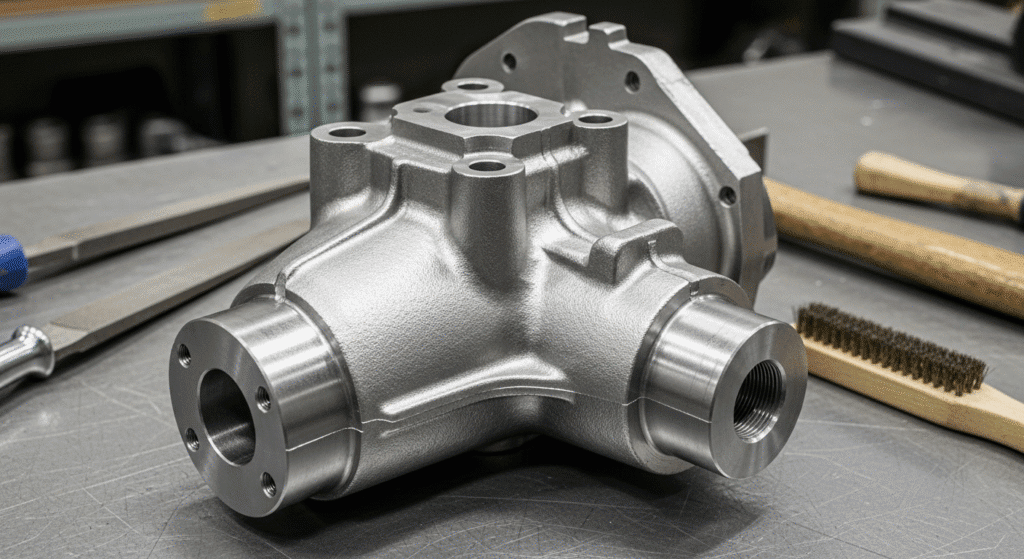

The revealed metal tree shows multiple finished castings still attached to the central sprue system.

Bandsaws or cut-off saws separate individual parts from the sprue tree. The leftover sprue and runners get recycled as scrap metal.

Cut areas where parts connected to gates require grinding to achieve smooth surfaces.

Many stainless steel castings undergo specific heat treatments to optimize their mechanical properties. Austenitic grades like 304 and 316 might receive solution annealing treatment.

Final operations include grinding away gate marks, blasting or pickling for appearance, and machining any critical features requiring ultra-tight tolerances. Most investment castings need minimal finishing thanks to their smooth as-cast surface of 125 micro-inches or better.

| Aspect | Investment Casting | Sand Casting | Die Casting | CNC Machining |

|---|---|---|---|---|

| Materials | All metals including stainless steel, superalloys | All metals including stainless steel | Limited to aluminum, zinc, magnesium | All machinable metals |

| Tolerances | ±0.005″ typical | ±0.030″ typical | ±0.005″ typical | ±0.001″ or better |

| Surface Finish | 125 micro-inches | 250-500 micro-inches | 50-100 micro-inches | 32 micro-inches or better |

| Part Complexity | Excellent – undercuts, thin walls possible | Limited – requires draft angles | Good – limited by die design | Limited by tool access |

| Part Size Range | Few grams to 50+ lbs | Ounces to tons | Few grams to 30 lbs (non-ferrous) | Any machinable size |

| Tooling Cost | Medium ($5,000-50,000) | Low ($500-5,000) | High ($25,000-250,000+) | None (programming only) |

| Per-Part Cost | Medium | Low | Very low at high volume | High for complex parts |

| Ideal Volume | 100-10,000 parts | 1-1,000 parts | 10,000+ parts | 1-100 parts |

| Lead Time | 4-8 weeks | 2-4 weeks | 8-16 weeks | Days to weeks |

| Material Waste | Low (10-30%) | Low (20-40%) | Very low (<10%) | High (50-90%) |