Manufacturing involves tracking products through various identification systems. Heat numbers, lot numbers, and batch numbers might seem similar, but they serve different purposes in quality control and traceability.

The main difference between heat number, lot number, and batch number is their traceability scope. A heat number identifies a specific melt of metal from a furnace. A lot number tracks items grouped under the same process or material. A batch number is the same as a lot number.

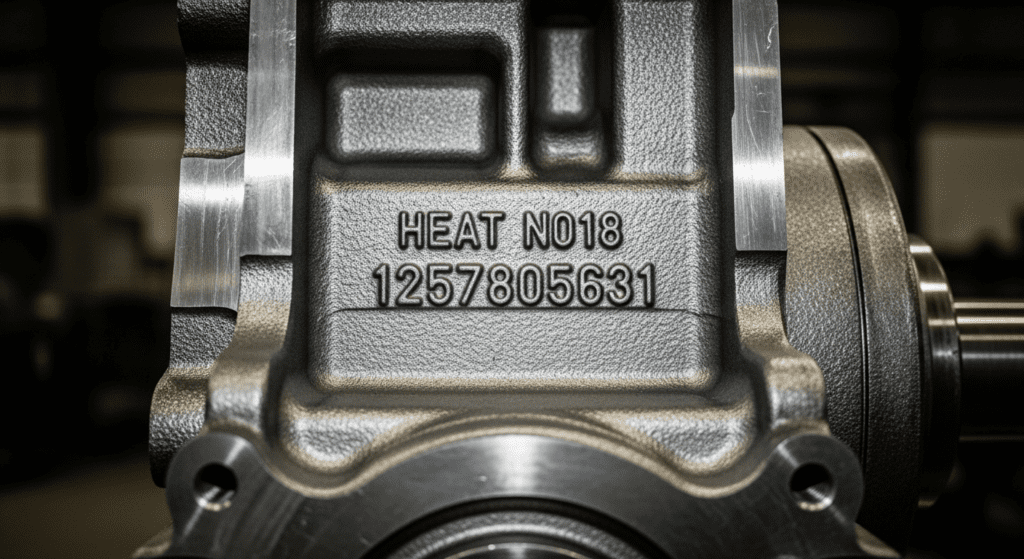

A heat number is a unique identification code stamped on metal products after they come out of the furnace at a steel mill. This special number links the metal to its specific batch of molten steel.

Each time a furnace produces molten steel, it gets assigned a unique heat number. The number tracks important details like chemical composition, temperature data, and processing methods used during production.

Heat numbers appear mainly in metal manufacturing industries. You’ll find them on steel plates, pipes, beams, and other metal products.

The heat number connects to a mill test certificate (MTC) that contains all the test results. This certificate shows the metal’s chemical makeup, strength properties, and whether it meets required standards.

A lot number identifies a specific quantity of products made at one time under the same conditions. It’s used across many industries, not just metalworking.

In metal manufacturing, a lot number often relates to secondary processing like heat treatment. While one heat of steel provides the raw material, that material might go through different processing steps. Each processing batch gets its own lot number.

Think of it this way. A single heat can be divided into several lots. For instance, if a manufacturer takes steel from one heat and applies different heat treatments to different portions, each treated portion becomes a separate lot with its own number.

A batch number serves the same purpose as a lot number – the terms are often used interchangeably. Both identify a specific quantity of products manufactured together.

In some regions, particularly the UK, manufacturers prefer using “batch number” instead of “lot number.” But they mean the same thing. Both help track groups of products made under identical conditions during the same production run.

Heat numbers can connect to multiple lot or batch numbers. Here’s how this works in steel production:

One heat of steel might produce 100 steel plates. If those plates undergo different treatments later, they could receive different lot numbers. For example, 50 plates get one heat treatment process (Lot A) while the other 50 get different treatment (Lot B).

The relationship flows like this: