The key difference between hot chamber and cold chamber die casting lies in where the furnace is located. Hot chamber systems have the furnace built into the casting machine itself, while cold chamber systems keep the furnace separate.

Hot chamber die casting works best for low-melting-point metals like zinc and magnesium. Cold chamber die casting handles high-melting-point metals like aluminum and copper alloys. Understanding these differences helps manufacturers choose the right process for their specific parts and production needs.

Cold chamber die casting separates the melting furnace from the injection system. Molten metal is ladled from an external furnace into a shot chamber for each casting cycle.

This process works by using a gooseneck system that draws metal from the furnace and injects it into the die. A plunger moves through the gooseneck chamber, forcing molten metal through a nozzle and into the die cavity. The entire injection system remains constantly immersed in the molten metal bath.

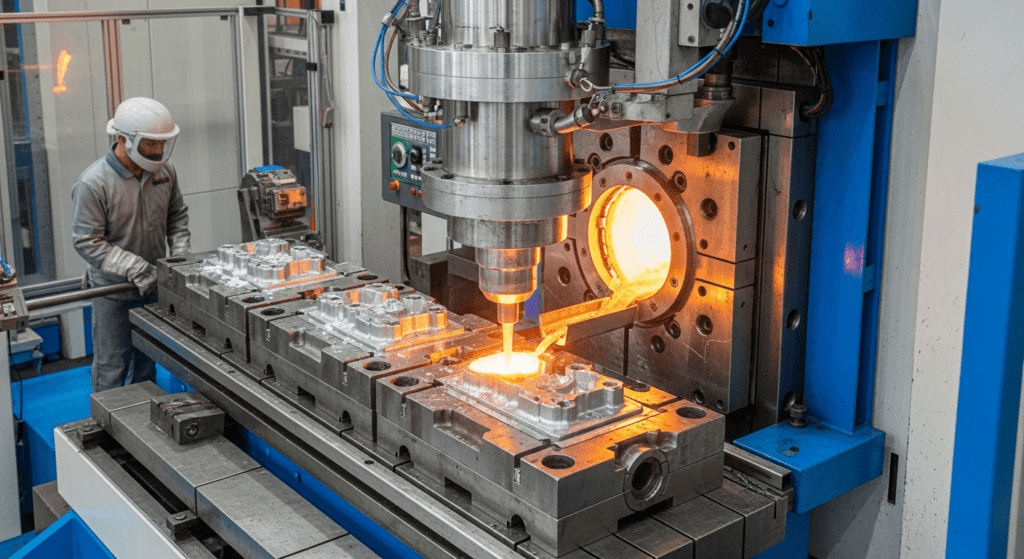

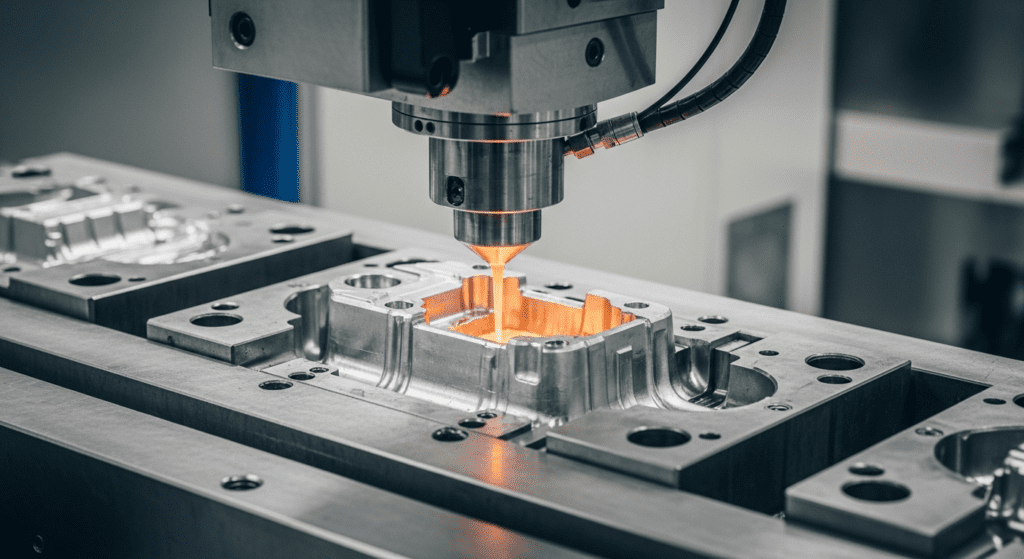

Cold chamber die casting separates the melting furnace from the injection system. Molten metal is ladled from an external furnace into a shot chamber for each casting cycle.

The process begins when molten metal is poured into the shot chamber. A hydraulic plunger then drives the metal into the die cavity under high pressure. After the part solidifies and is ejected, the cycle repeats with a fresh pour of molten metal.

Hot chamber systems integrate the furnace directly into the machine, creating a unified system.

Cold chamber systems maintain complete separation between the melting furnace and the injection mechanism.

Hot chamber die casting processes low-melting-point alloys. Zinc alloys dominate, followed by magnesium and certain lead-based alloys. These materials melt below 1,000°F and won’t damage the submerged injection system.

Cold chamber die casting handles high-melting-point alloys. Aluminum alloys represent the most common choice. Copper alloys, brass, and even some ferrous materials work in cold chamber systems.

Production speed varies significantly between the two methods. Hot chamber systems complete cycles in 15 to 30 seconds for most parts.

Cold chamber cycles typically run 45 to 90 seconds. The additional time comes from ladling molten metal and allowing for proper shot chamber filling.

Hot chamber systems operate at lower injection pressures. Typical pressures range from 1,000 to 5,000 PSI.

Cold chamber systems generate much higher pressures. Standard pressures reach 10,000 to 15,000 PSI. Some machines achieve over 20,000 PSI.

Hot chamber die casting produces smaller parts efficiently. Most parts weigh less than 10 pounds. The process excels at high-volume production of components under 5 pounds.

Cold chamber die casting handles much larger parts. Parts weighing 50 pounds or more are common. Some specialized machines produce castings exceeding 100 pounds.

Hot chamber die casting offers lower per-part costs for suitable applications. The faster cycles and integrated design reduce operating expenses. Tooling costs tend to be lower due to smaller part sizes and simpler designs.

Cold chamber die casting involves higher operating costs. The slower cycles and manual metal transfer increase labor needs.

Both processes can produce high-quality parts when properly controlled. Hot chamber casting typically yields excellent surface finish and dimensional accuracy. The consistent temperature and lower injection pressure reduce internal stresses.

Cold chamber casting may introduce more porosity due to turbulent metal flow during ladling. However, the high injection pressures can produce denser parts with superior mechanical properties.

Both processes produce high-quality parts when properly executed. The choice depends on matching the process capabilities to the specific part requirements and production volumes.