Deburring is the process of removing small, unwanted pieces of metal from the edges or surfaces of a cast part. These unwanted pieces are called burrs or flash. They are a normal by-product of casting and other manufacturing processes.

Deburring takes place after the casting is removed from its mold and the main excess metal—such as gates and risers—has been cut away. It is part of the final cleaning and finishing steps that make the part safe, functional, and ready for use.

If the two halves of a mold don’t seal tightly, molten metal can leak into the small gap between them. When the metal cools, it forms a thin ridge called flash along the seam.

After casting, gates and runners are cut off. If the cut is not perfectly smooth, it leaves a small raised edge of metal around the cut area.

Worn cutting tools, grinding wheels, or mold surfaces lose their sharpness. This can cause metal to smear or deform instead of cutting cleanly, leaving burrs behind.

If drilling or milling speeds and feeds are not set correctly, the cutting tool can push metal to the side instead of removing it cleanly. This creates curled or rough edges.

Rapid heating and cooling can cause sharp corners or edges to deform slightly. This may create small protrusions that need to be removed.

Form when material is squeezed sideways during a cutting or trimming operation, creating a raised ridge along the edge. The name comes from Poisson’s effect, where material deforms laterally when compressed.

Occur when the cutting tool pushes material ahead of it, causing it to curl over the edge rather than cleanly separate. This creates a lip that folds back over the edge of the part.

Jagged, fractured edges caused when material breaks away abruptly as the tool exits the cut. This type of burr often has a rough, torn appearance.

A thin, unwanted layer of metal that forms where molten metal seeps into small gaps in the mold assembly, usually along parting lines or around poorly fitted cores.

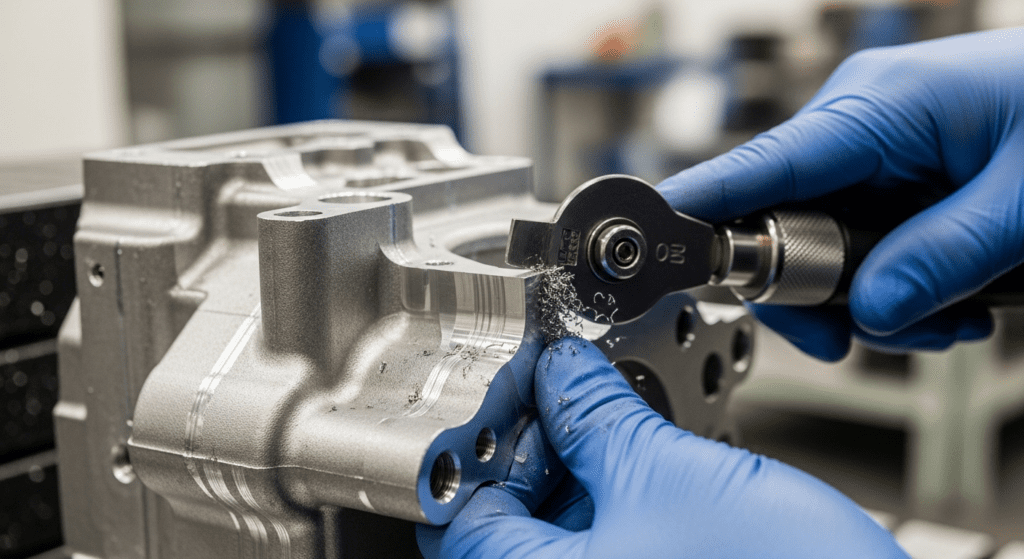

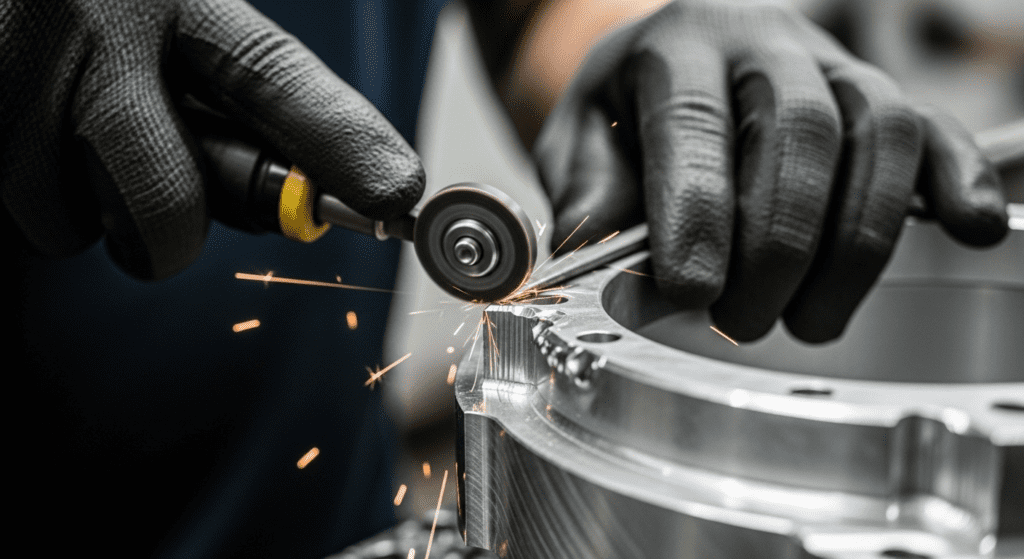

Manual deburring involves removing burrs by hand using basic tools. Common tools include flat files, round files, scrapers, deburring knives, abrasive stones, sandpaper, and handheld rotary grinders.

The operator inspects the part visually or by touch, then guides the tool along the burr to cut or grind it away. This process can be done at a workbench or on the production floor.

The precision comes from the operator’s control, allowing them to work on complex shapes, irregular edges, and delicate surfaces.

Mechanical deburring uses powered machines to remove burrs through physical abrasion or friction.

Common systems include:

Mechanical methods are often designed for batch processing, with adjustable media types, rotation speeds, and cycle times to match the part’s material and burr size.

Thermal deburring uses heat from controlled combustion to vaporize burrs.

The process starts by placing parts inside a sealed chamber. The chamber is filled with a mixture of combustible gas (such as natural gas) and oxygen. The mixture is ignited, creating a short-duration, high-temperature flame that burns away thin burr material.

The base metal remains intact because the combustion is extremely brief—usually milliseconds—only affecting small, thin burrs. TEM is particularly effective on internal burrs in holes, channels, and intersecting passages that are inaccessible by physical tools.

Electrochemical deburring removes burrs through an electrolytic process that dissolves metal at a controlled rate.

The burr area is positioned close to a shaped electrode, and both are submerged in an electrolyte solution (often sodium nitrate or similar). A direct electrical current is applied, causing metal ions at the burr to dissolve into the electrolyte.

Because the current is focused on high points—like burr edges—the process removes burrs without changing the surrounding surface geometry. ECD is precise and often used for edges where accuracy is critical.

Cryogenic deburring uses extreme cold to make burrs brittle so they can be broken off mechanically.

Parts are placed in a chamber and cooled with liquid nitrogen or refrigerated air to temperatures far below freezing. Burrs, being thin, freeze more quickly and become brittle before the bulk of the part is affected.

Once the burrs are brittle, the parts are tumbled or blasted with small pellets (often plastic media) that knock the burrs away. The process is fast and maintains the integrity of the base part.

High-pressure water jet deburring removes burrs using streams of water pressurized to tens of thousands of pounds per square inch (psi).

The water is directed through a nozzle and aimed precisely at the burr. The high kinetic energy of the water physically shears the burr from the part without introducing heat.

Multiple nozzles can be arranged to hit different burr locations simultaneously. The process also rinses the part clean during deburring, leaving no abrasive residue.

Laser deburring uses a concentrated beam of light to vaporize burr material.

A laser system targets the burr location and emits a high-energy pulse that heats the burr material to its vaporization point. This removes the burr with minimal mechanical contact.

Laser systems can be programmed to trace specific paths, ensuring only the burrs are removed while the surrounding surface remains untouched. The precision comes from both the laser’s beam control and the ability to focus on very small areas.