In metal manufacturing, the journey from raw stock to a finished, high-performing component is rarely complete after the initial shaping. Two finishing processes—grinding and deburring—play critical roles in ensuring that parts meet design specifications.

They are often confused because both involve refining a part’s surface. But here’s the key: grinding shapes surfaces and improves dimensional precision, while deburring removes sharp edges and burrs for safety and assembly integrity.

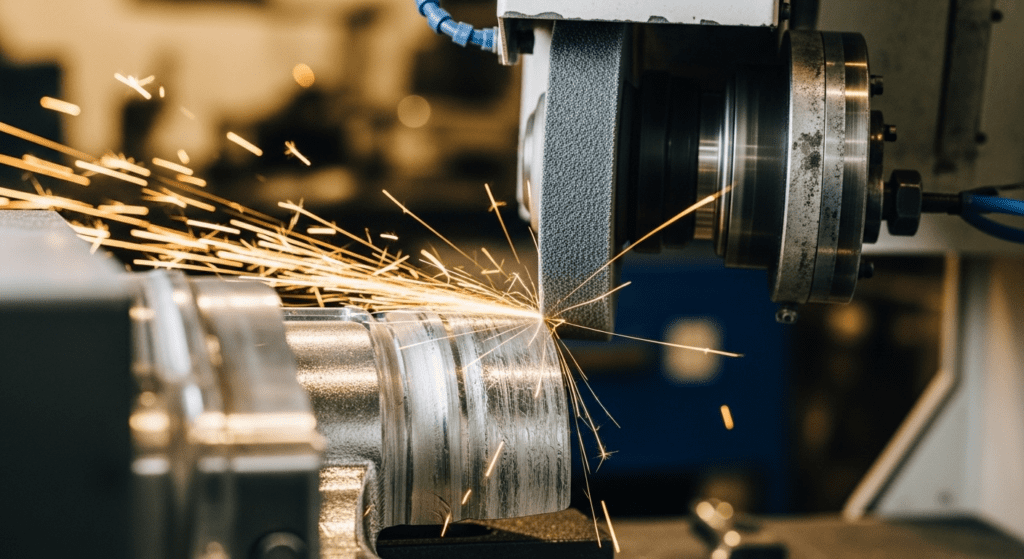

Grinding is a precision metalworking process in which abrasive particles, bonded into a rotating wheel, belt, or disc, remove material from a workpiece through mechanical friction and cutting action.

Unlike general cutting or machining—which uses sharp-edged tools to shear off material—grinding uses countless microscopic cutting points on the abrasive surface. Each abrasive grain acts like a tiny, hard-edged cutting tool, chipping away minute fragments of metal as the wheel spins at high speed.

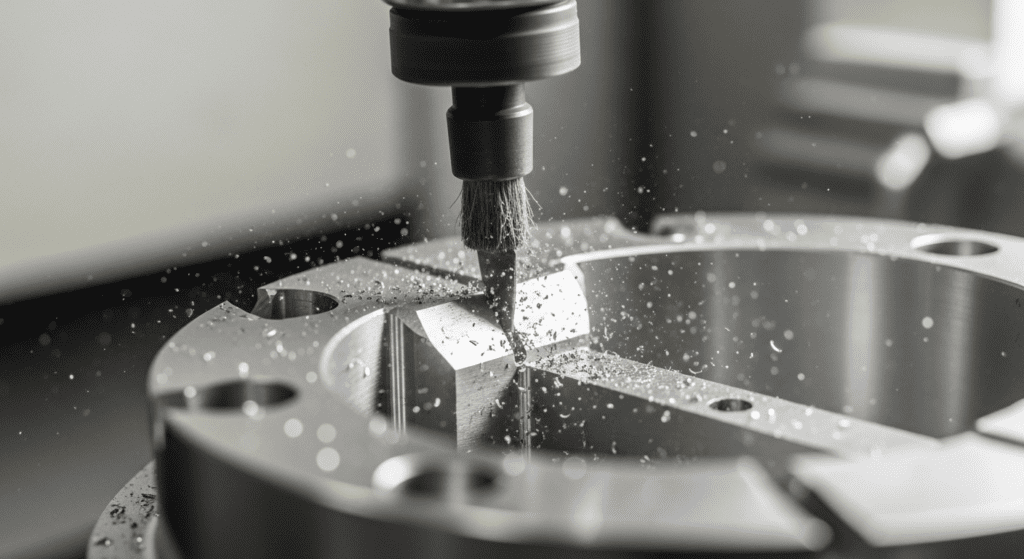

Deburring is a finishing process specifically focused on removing burrs—small, often sharp protrusions of material—that form on the edges or surfaces of a workpiece after machining, cutting, drilling, stamping, laser cutting, or grinding.

When looking at grinding and deburring side by side, the differences are clear in purpose, timing, scope, tools, and impact. While they are complementary processes, each addresses a distinct part of the finishing workflow.

Consider a laser-cut steel flange:

Grinding and deburring are complementary processes, not alternatives. Grinding creates the precise geometry and smooth surfaces that meet engineering requirements. Deburring removes the small, sharp imperfections that could compromise safety, assembly, or long-term performance.

Skipping either step risks sending out a part that looks good on paper but fails in the field.

Integrate both processes into your finishing workflow. Grind for precision, deburr for safety—and deliver components that are both exact and dependable.