In industrial metal manufacturing, deburring and polishing are often mentioned in the same breath — and for good reason. Both are finishing processes that improve the quality, performance, and appearance of metal parts. Yet, they serve very different purposes, occur at different stages of production, and use different tools and techniques.

Deburring focuses on removing sharp edges, burrs, and other dangerous or performance-limiting imperfections left after cutting, machining, or forming. Polishing, by contrast, is about refining the entire surface to achieve a smooth, uniform, and often visually appealing finish.

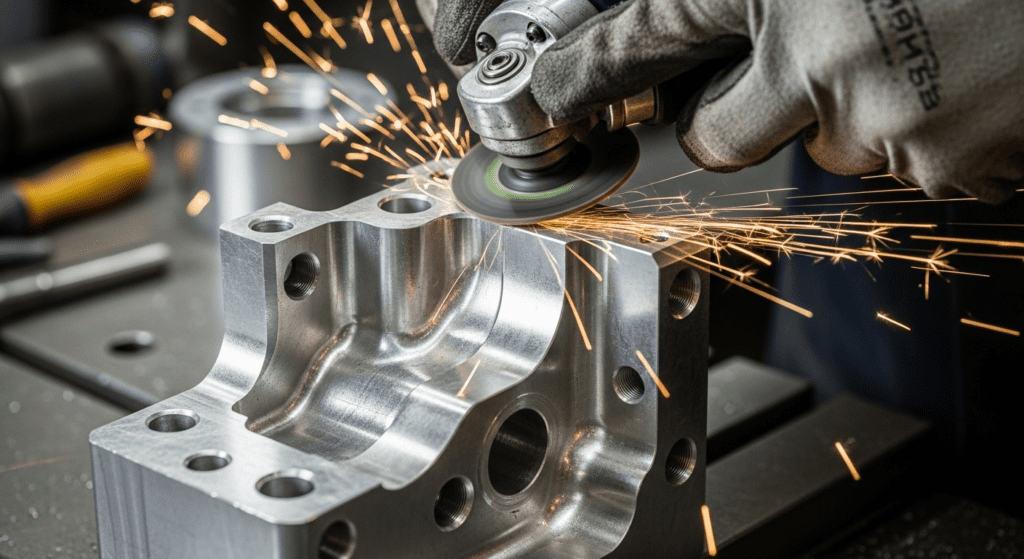

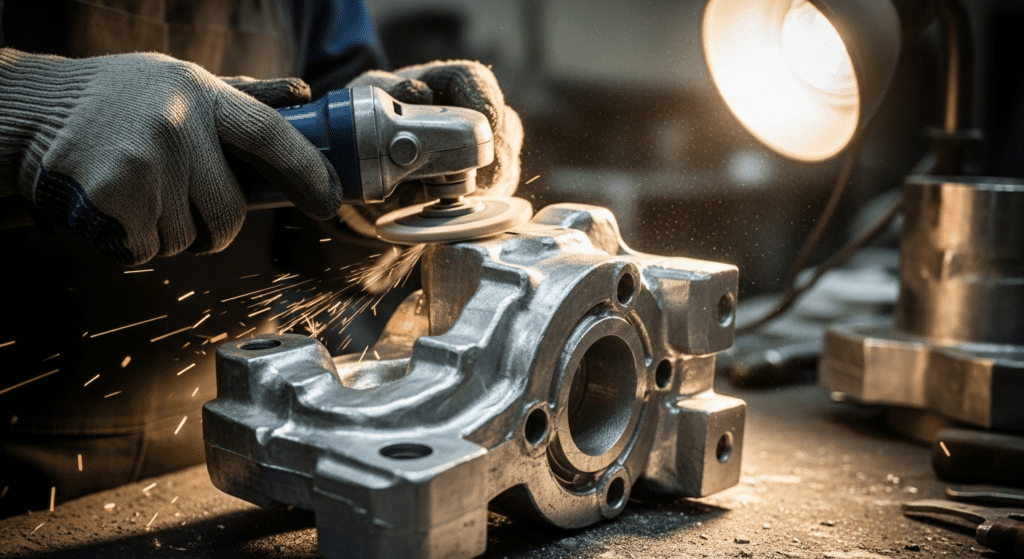

Deburring is the industrial process of removing burrs — the small, raised projections or rough edges that form on a workpiece during manufacturing operations such as machining, drilling, laser cutting, stamping, or casting.

Burrs are usually unwanted byproducts of material displacement or tearing when a cutting tool exits the workpiece or when molten metal solidifies unevenly in a mold. They may appear as sharp ridges along edges, thin slivers hanging from drilled holes, or fine whiskers on intricate features.

Deburring is typically one of the earliest finishing steps after the part leaves the cutting or forming stage. It can be performed manually (files, scrapers, abrasive pads), mechanically (grinding wheels, belt sanders, rotary brushes), in mass-finishing equipment (vibratory bowls, tumblers), or by specialized technologies such as:

Regardless of method, the aim is precise removal of only the unwanted material, leaving a clean, uniform edge that meets dimensional and surface specifications.

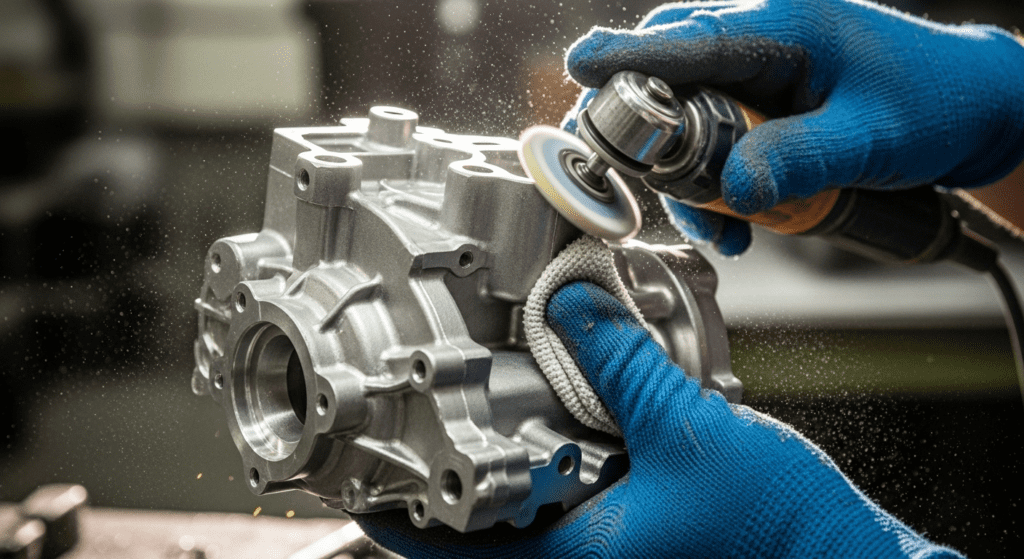

Polishing is the controlled refinement of a metal surface using fine abrasives to remove microscopic irregularities, scratches, pits, or oxidation and produce a desired smoothness, reflectivity, or texture.

Polishing usually occurs after all shaping, deburring, and coarse finishing steps are completed. It is the “final touch” in the production sequence, ensuring the surface meets required aesthetic and technical standards, such as a specific surface roughness (Ra value) or a uniform grain direction.

While deburring targets localized protrusions, polishing treats the entire surface area to achieve a consistent finish. This process may be functional — reducing friction, improving corrosion resistance, enhancing cleanability — or purely cosmetic, creating a bright or mirror-like appearance for customer-facing parts.

Deburring: Removes sharp burrs and jagged edges that can cause injury, hinder assembly, or compromise performance. Focused on eliminating localized hazards and ensuring accurate, safe geometry.

Polishing: Refines the entire surface to improve smoothness, luster, and performance. Aims to perfect the surface texture for appearance, reduced friction, corrosion resistance, or coating readiness.

Deburring: Removes larger, localized imperfections — physically significant protrusions along edges, holes, or part transitions.

Polishing: Removes a microscopic, uniform layer of material across the whole surface, evening out fine peaks and valleys from previous processes.

Deburring: Performed immediately after machining, cutting, stamping, or forming; an early finishing step that prepares the part for subsequent operations.

Polishing: Conducted as a final or near-final step after deburring and any coarse finishing, once edges and geometry are fully optimized.

Deburring: Uses coarse to medium abrasives, cutting tools, wire brushes, and advanced processes like thermal deburring, electrochemical deburring, or abrasive flow machining.

Polishing: Uses fine to ultra-fine abrasives, buffing wheels, polishing compounds, electropolishing baths, or vibratory polishing media for consistent, high-quality finishes.

Deburring: Evaluated by edge uniformity, absence of burrs, and maintenance of dimensional tolerances at edges, holes, and mating surfaces.

Polishing: Measured by surface roughness (Ra), reflectivity, uniform grain, and absence of scratches, pits, or surface blemishes.