We understand that every snatch block application has unique specifications, from working load limits to environmental conditions.

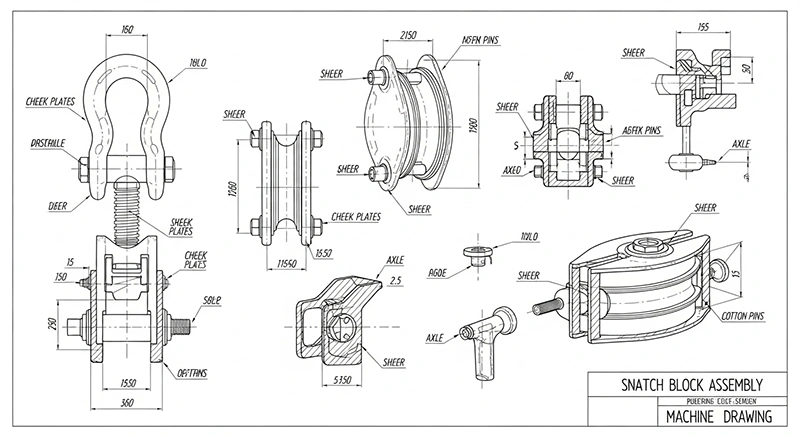

Our team specializes in customizing every aspect of your snatch blocks - from selecting the ideal material grade (high-strength steel or ductile iron) to engineering sheave diameters that perfectly match your cable sizes.

We can incorporate custom side plate designs, specialized bearing configurations, and unique mounting patterns that integrate seamlessly with your existing rigging systems.

Whether you need compact 4-inch blocks for light recovery work or massive 36-inch sheaves for heavy industrial lifting, we adapt our casting process to your exact specifications.

Our customization capabilities extend beyond size - we can engineer blocks with specific pin diameters, custom hook openings, integrated swivel mechanisms, or specialized drainage features for marine environments.

From single-sheave to multi-sheave configurations, we deliver snatch blocks tailored to your precise operational demands and safety factors.

Beyond standard configurations, we help you select the optimal combination of materials and protective finishes for your operating conditions.

Choose from various steel grades for maximum strength or ductile iron for shock absorption.

We offer customized surface treatments, including hot-dip galvanizing for corrosion resistance, specialized powder coatings in your brand colors, or hard-chrome plating for wear surfaces. Every detail - from grease fitting locations to safety latch designs - can be modified to meet your specific maintenance and safety protocols.

KT Metal Casting has earned the trust of crane manufacturers, rigging suppliers, and recovery equipment companies who depend on us for snatch blocks that perform flawlessly when failure isn't an option. We know that lives and assets depend on our quality.

Smart rigging companies choose to work with us because we understand the critical nature of their equipment. When you face demanding applications or urgent project requirements, you can count on our team to deliver solutions that maintain your safety standards.

Our foundry team treats every snatch block like it will be used in the most critical lift because we understand these components are the backbone of safe rigging operations.

| Project Description | Dependable snatch block castings for crane operations, marine rigging, recovery equipment, and industrial lifting applications that demand absolute load security. |

| Capabilities | Primary: Reliable sand casting with rigorous quality control Secondary: Precision machining, load testing, customer-focused technical support |

| Dimensions | Sheave diameters from 4″–36″, designed to accommodate specific cable sizes and working load limits |

| Tolerances | ±0.005″ standard precision ±0.003″ available for critical bearing bores and pin interfaces |

| Materials | High-strength steel, ductile iron, alloy steel, and specialized grades selected for maximum load capacity and wear resistance |

| Finish | Professional machined surfaces with optional galvanizing, powder coating, and corrosion-resistant treatments for marine and outdoor environments |

| Industry Use | Crane operations, marine rigging, mining equipment, forestry machinery, and emergency recovery vehicles |

| Volume | Flexible production from safety test prototypes to full runs up to 2,000 pieces |

| Delivery | Reliable on-time delivery throughout North America and international markets |