Every handwheel we produce reflects our commitment to excellence, with personalized attention to your most demanding specifications.

Our quality-obsessed team delivers bespoke solutions across every customizable element - from material selection (premium gray iron, certified ductile iron, or marine-grade stainless steel) to precision-machined bore tolerances within ±0.003″.

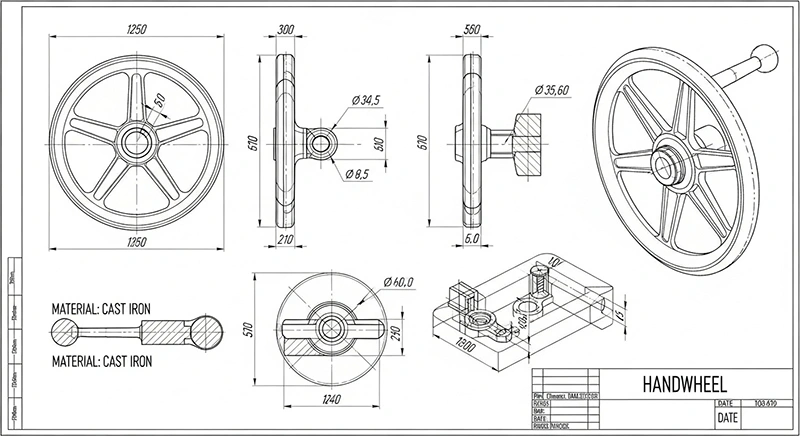

We personalize spoke designs for optimal strength-to-weight ratios, engineer custom rim cross-sections for operator comfort, and create proprietary hub geometries that ensure zero play in your assemblies. Each handwheel undergoes rigorous dimensional verification and surface finish inspection.

Your specifications drive our zero-defect approach, whether crafting miniature 2-inch precision handwheels or engineering massive 24-inch industrial giants.

Our bespoke manufacturing process allows complete personalization - custom bore configurations with specialized keyways, proprietary mounting patterns, laser-etched positioning marks, or integrated locking mechanisms.

We maintain strict quality control through every personalized feature, from balanced spoke arrangements that eliminate vibration to custom-formulated alloys that meet your exact strength requirements. Our metallurgical lab ensures every casting meets certified material properties.

Quality extends through every surface treatment, with bespoke finishing options that match your exacting standards.

Select from our premium finishing suite - mirror-polished stainless steel for pharmaceutical cleanrooms, specialized anti-microbial coatings for food processing, or custom powder coating matched to your exact RAL specifications.

Our personalized approach includes hand-deburred edges, precision-ground mating surfaces, and custom laser marking for traceability. Every bespoke handwheel receives individual quality certification, documenting dimensional accuracy, material composition, and surface finish specifications.

KT Metal Casting has earned ISO 9001:2015 certification and the trust of manufacturers who accept nothing less than perfection. Our bespoke handwheels meet the strictest quality standards - from FDA-compliant finishes to nuclear-grade material certifications.

Industry leaders choose our personalized approach because we document every aspect of quality - from raw material mill certificates to final dimensional reports. When your reputation depends on flawless performance, our bespoke handwheels deliver the reliability you need with full traceability.

Our quality team treats every custom handwheel as a reflection of our craftsmanship, implementing statistical process control and 100% inspection protocols that guarantee your specifications are exceeded.

| Project Description | Premium handwheel castings with personalized specifications for critical valve systems, precision machinery, and applications demanding uncompromising quality. |

| Capabilities | Primary: Precision sand casting with statistical process control Secondary: CNC machining, certified material testing, bespoke design optimization |

| Dimensions | Personalized diameters from 2″–24″, engineered to your exact torque calculations and ergonomic requirements |

| Tolerances | ±0.003″ precision standard ±0.001″ achievable for critical interfaces with specialized fixturing |

| Materials | Certified gray iron (ASTM A48), ductile iron (ASTM A536), stainless steel (316L/304), aluminum (356-T6), bespoke alloy formulations |

| Finish | Premium finishes including electropolishing, passivation, hard anodizing, and personalized texture patterns with documented Ra values |

| Industry Use | Pharmaceutical valves, aerospace controls, nuclear equipment, semiconductor manufacturing, and precision instrumentation |

| Volume | Bespoke quantities from single prototype validation to production runs up to 3,000 pieces with consistent quality |

| Delivery | Guaranteed delivery schedules with expedited options for critical requirements |