Binders are the glue that holds sand together in sand casting, allowing it to maintain its shape when molten metal is poured into the mold. Without binders, the sand would simply collapse, making it impossible to create the precise metal parts we need for everything from engine blocks to decorative art pieces.

The right binder can mean the difference between a perfect casting and a costly failure. Each type has its own strengths, costs, and ideal applications.

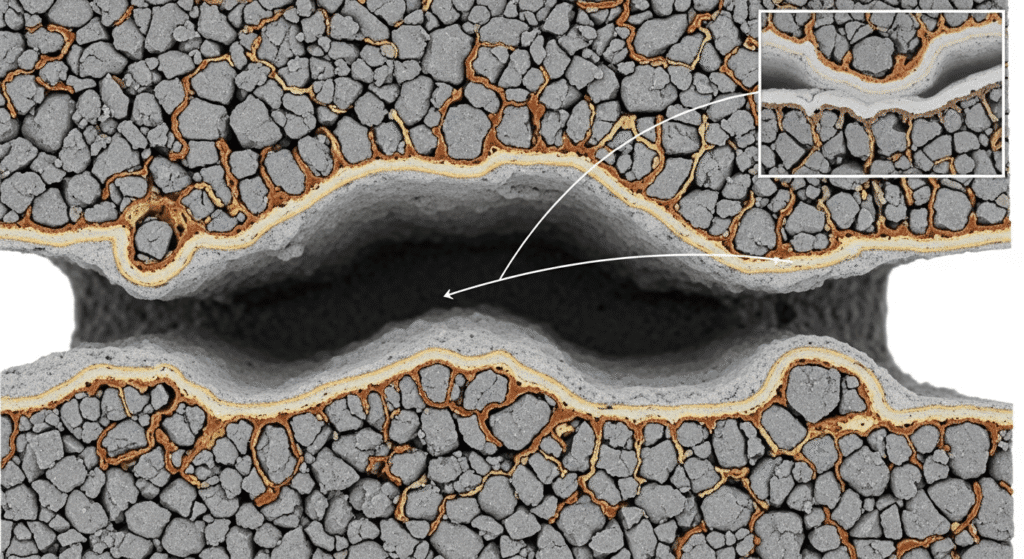

Bentonite clay is the workhorse of the foundry world, used in about 70% of all sand molds. This special clay swells when it gets wet, creating a sticky coating around each sand grain that binds them together like natural glue.

What makes bentonite so popular? It’s cheap, reusable, and forgiving. You can use the same sand-clay mixture hundreds of times, just adding a bit more clay and water as needed.

The clay creates what foundry workers call “green sand” – not because it’s actually green in color, but because it’s moist and ready to use, like green wood.

Adding cereal binders (yes, similar to breakfast cereal ingredients) or sugar-based materials to clay creates a stronger bond that breaks down cleanly when heated. These organic additives burn away when the hot metal hits them, making it easier to remove the casting from the mold.

Think of it like adding flour to water to make paste – except this paste needs to withstand 2,000-degree metal. The cereal binders improve the sand’s ability to collapse after casting, preventing cracks in your finished part.

Sea coal isn’t actually from the sea – it’s finely ground coal that creates a reducing atmosphere when the hot metal enters the mold. This prevents the metal from sticking to the sand and gives you a smoother surface finish.

When the coal burns, it creates a thin layer of gas between the metal and sand. It’s like the non-stick coating on a frying pan, but created by chemistry rather than manufacturing.

Other additives like wood flour, corn flour, and pitch work similarly, each bringing specific benefits to different casting situations.

Portland cement mixed with sand creates an incredibly strong mold that can handle the most demanding castings. Unlike bentonite, cement-bonded sand becomes rock-hard and can’t be reused.

Fire clay and other inorganic clays offer a middle ground – stronger than bentonite but not as permanent as cement. They’re perfect when you need extra strength but still want some reusability.

Phenolic resins are the precision tools of sand binding. They create molds with exceptional dimensional accuracy and can reproduce fine details that clay binders would blur.

These resins cure through heat or chemical catalysts, creating a rigid mold that won’t shift or compress. They’re like the difference between molding clay and 3D printing – one gives you artistic freedom, the other gives you precision.

Furan resins excel at room-temperature curing, making them ideal for large molds that can’t fit in an oven. Mix the resin with sand and a catalyst, and you’ve got about 30 minutes to shape your mold before it hardens.

The beauty of furan systems? They produce minimal gas and smoke during pouring, resulting in cleaner castings with fewer defects.

These versatile resins combine the best of both worlds – the strength of phenolics with the ease of use of furans. They cure at room temperature but create bonds strong enough for the most demanding applications.

Polyurethane systems are particularly popular for making cores (the sand shapes that create hollow spaces inside castings). They break down easily after casting, making core removal a breeze.

Ester-hardened resins use liquid esters as catalysts, creating an extremely fast cure that’s perfect for high-production environments. The mold becomes rigid in seconds rather than minutes.

This speed comes with exceptional accuracy. These systems can hold tolerances that would be impossible with traditional clay binders.

Cold-box systems revolutionized core making by curing instantly when exposed to amine gas. Imagine spray paint that hardens the moment it hits the surface – that’s essentially how cold-box binders work.

The process is so fast that cores can be made, cured, and assembled in minutes rather than hours. This speed makes it the go-to choice for automotive and other high-volume production.

Shell molding resins are pre-coated onto sand and activated by heat. The sand is dumped onto a hot pattern, the resin melts and bonds, and excess sand falls away, leaving a thin shell.

This creates incredibly smooth surface finishes and precise dimensions. It’s like the difference between painting with a brush versus airbrushing – the results are just that much cleaner.

Water glass binders cure when exposed to CO2 gas, creating a chemical reaction that turns liquid sodium silicate into solid silica. The transformation happens in seconds, making it perfect for quick mold production.

The downside? These molds are incredibly hard to break down after casting. It’s like trying to dissolve glass – possible, but not easy.

Geopolymer binders represent the cutting edge of foundry technology. They create ceramic-like bonds without organic chemicals, making them environmentally friendly and odor-free.

These binders work through a process similar to how concrete cures, but much faster. They’re particularly valuable for aluminum casting where low gas generation is critical.

Portland cement creates the strongest sand molds possible, essentially turning sand into concrete. These molds can sit for months without degrading and handle the heaviest castings.

The trade-off is permanence. Once cured, cement-bonded sand must be broken apart with hammers or vibration equipment.

Different casting processes demand different binder systems. Here’s how to match your binder to your process:

Bentonite clay is by far the most economical option. It costs pennies per pound, can be reused hundreds of times, and requires only water for activation. Most small foundries start with bentonite systems.

Choose organic binders when you need easy sand reclamation and good collapsibility. Pick inorganic binders when you need maximum strength, no organic emissions, or extended mold storage life.

Generally no – different binders have incompatible chemistry. Mixing them usually weakens both systems. However, some additives like cereal binders can enhance clay systems when properly formulated.

Most systems use 1-6% binder by weight. Clay systems typically need 6-10% bentonite, while resin systems often work with just 1-2%. Too much binder makes sand removal difficult.

Clay binders last indefinitely when kept dry. Liquid resins typically last 6-12 months when properly stored. Pre-coated resin sand has the shortest life – usually 3-6 months maximum.