Cast aluminum is aluminum that’s been melted and poured into a mold to create a specific shape. Once the metal cools and hardens, you get a solid part that matches the exact shape of the mold—from engine blocks to cookware to outdoor furniture.

This manufacturing process transforms raw aluminum into complex, detailed parts that would be difficult or impossible to make any other way. The metal flows into every corner of the mold, capturing fine details and creating hollow sections that other methods can’t achieve.

Sand casting is the oldest and simplest aluminum casting method, where molten aluminum gets poured into a mold made of sand mixed with a binding agent. The sand mold breaks away after the metal cools, making this perfect for one-off parts or small production runs.

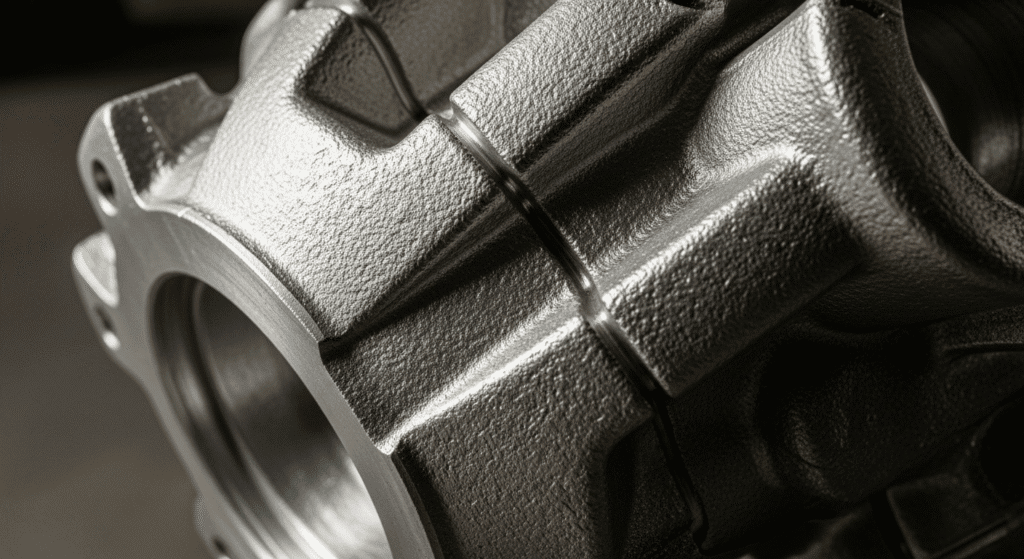

This method works best for large parts like engine blocks and pump housings. While the surface finish isn’t as smooth as other methods, sand casting handles complex shapes and costs less for small quantities.

Investment casting creates the most precise and detailed aluminum parts by using a wax pattern covered in ceramic. The wax melts out, leaving a hollow ceramic mold that produces parts with excellent surface finish and tight tolerances.

You’ll find investment cast parts in aerospace components, medical devices, and jewelry. Though more expensive than other methods, it delivers unmatched accuracy for small, complex parts.

High-pressure die casting shoots molten aluminum into steel molds at pressures up to 25,000 psi. This creates dense, strong parts with excellent surface finish in seconds rather than minutes.

Perfect for high-volume production, this method makes everything from car transmission cases to laptop frames. The steel molds cost more upfront but last for hundreds of thousands of parts.

Permanent mold casting uses reusable metal molds and gravity or low pressure to fill them with aluminum. This produces stronger parts than sand casting with better surface finish and dimensional accuracy.

Manufacturers use this method for wheels, pistons, and gear blanks. The metal molds create consistent quality and last for thousands of castings, making it ideal for medium to high production volumes.

Different aluminum alloys offer specific properties for various applications:

The main difference between these terms is how the aluminum gets shaped into useful products. Aluminum is just the raw metal, while cast, wrought, and extruded describe three different manufacturing processes that give you different properties and shapes.

Aluminum itself is the pure metal element—a lightweight, silver-colored metal that makes up 8% of Earth’s crust. Everything else starts with this base material.

Cast aluminum forms when you melt aluminum and pour it into a mold. Like making ice cubes, the liquid metal takes the exact shape of the container and hardens.

This process creates complex 3D parts with hollow insides—think engine blocks or decorative furniture. The downside? Cast parts have tiny air pockets inside that make them slightly weaker than wrought aluminum.

Wrought aluminum gets worked and shaped while solid through processes like rolling, hammering, or bending. This mechanical working crushes out air pockets and aligns the metal’s grain structure.

The result is stronger, denser aluminum that’s perfect for aircraft parts and structural beams. But you can only make simpler shapes—no complex internal cavities like casting allows.

Extruded aluminum is technically a type of wrought aluminum that’s pushed through a shaped die, like squeezing Play-Doh through a mold. You get long pieces with the same cross-section throughout—window frames, railings, and heat sinks.

This method creates precise, uniform shapes quickly and cheaply. The limitation? You can only make shapes that run straight in one direction.

Each method serves different needs. Cast aluminum handles complex 3D shapes, wrought aluminum provides maximum strength for simple shapes, and extrusion creates long, uniform profiles efficiently.

Cast aluminum typically has 40-50% of steel’s strength but weighs only one-third as much. This gives aluminum a better strength-to-weight ratio for many applications, especially where weight matters more than absolute strength.

Cast aluminum doesn’t rust like iron because it forms a protective aluminum oxide layer instantly when exposed to air. This thin, invisible layer prevents further corrosion, though aluminum can still corrode in extreme conditions like saltwater exposure.

Cast aluminum parts can last 20-100+ years depending on the environment and application. Indoor parts essentially last forever, while outdoor furniture typically lasts 20-30 years, and properly maintained engine blocks can exceed 200,000 miles.

Cast aluminum costs more than steel per pound but less overall due to lower processing temperatures and lighter weight. Initial mold costs run high, but per-part costs drop significantly in volume production, making it very economical for large runs.

Yes, you can weld cast aluminum, but it’s trickier than welding wrought aluminum due to porosity and impurities. TIG welding works best with proper preparation, though many cast parts are designed to avoid welding altogether.