You’re about to select an aluminum alloy for your next production run. Choose wrong, and you’ll face costly consequences.

Over 35% of casting rejections stem from porosity issues alone. Mechanical property differences between cast and wrought aluminum reach 30-40%. These aren’t just numbers on a spec sheet—they translate directly to structural failures, production delays, and cost overruns that can sink a project.

I’ve seen engineers specify cast aluminum for high-stress applications where its lower tensile strength of 140-280 MPa creates safety risks. Others choose expensive wrought aluminum for complex geometries that would’ve been more economical to cast. The confusion is real, and the stakes are high.

This technical comparison breaks down exactly when to use cast versus wrought aluminum. You’ll understand the manufacturing processes, mechanical properties, machinability differences, and real-world applications.

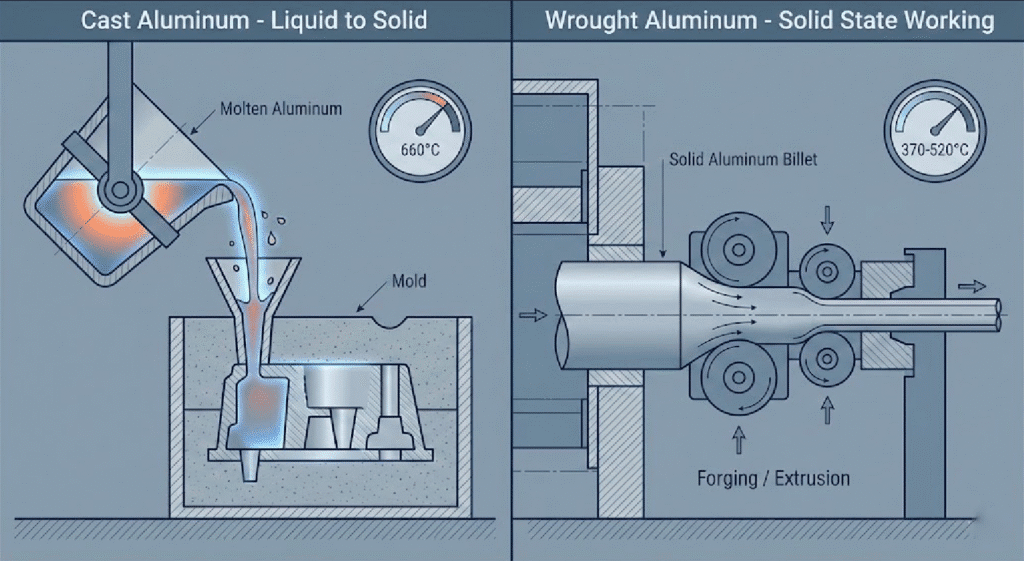

Cast and wrought aluminum differ fundamentally in how they’re manufactured. Cast aluminum is molten metal poured into molds, while wrought aluminum is mechanically worked in solid form.

Cast aluminum starts as liquid metal heated to around 660°C. You pour it into molds using three main methods: sand casting, die casting, or permanent mold casting.

Sand casting creates cavities by compacting sand around a pattern. It’s the most flexible method but produces surface finishes of 300-560 RMS. Die casting injects molten aluminum under high pressure—10 to 175 MPa—achieving tolerances as tight as ±0.1mm. Permanent mold casting uses reusable steel molds and gravity pour, hitting the middle ground with ±0.3-0.5mm tolerances and 50,000-100,000 cycle lifespans.

Wrought aluminum takes a completely different path. You start with solid billets or slabs and mechanically shape them through rolling, extrusion, or forging.

Rolling produces sheets, plates, and foils. Extrusion forces aluminum through dies to create shaped profiles—common alloys include 6063, 6061, and 6005. Forging heats aluminum to 370-520°C and mechanically works it, creating superior grain structure and the highest strength of all wrought processes.

The process you choose fundamentally changes the material’s internal structure. Cast aluminum solidifies from liquid, potentially trapping gas and creating porosity. Wrought aluminum’s mechanical working refines grain structure and eliminates internal defects.

Cast aluminum contains more than 22% alloying elements. Wrought aluminum keeps it under 4%.

This isn’t arbitrary. Cast alloys need higher silicon content to provide fluidity when molten. The silicon helps liquid aluminum flow into complex mold cavities and thin sections. Common cast alloys like A356, A380, and A360 rely on this higher alloying content.

Wrought alloys use a different strategy. The 6000 series combines moderate strength with excellent corrosion resistance for aerospace and automotive uses. The 7000 series—particularly 7075—delivers the highest performance under stress, making it the go-to for critical aerospace components.

Here’s what really matters: 85% of all aluminum production is wrought products. This tells you wrought aluminum dominates where mechanical properties and precision are critical.

Wrought aluminum is 30-40% stronger than cast aluminum. This difference stems directly from manufacturing processes.

Cast aluminum typically delivers 140-280 MPa tensile strength. High-performance die casting can push this to 310-340 MPa tensile and 260-280 MPa yield strength according to ASTM B557 standards. Advanced A356 processing reaches 320 MPa yield and 500 MPa ultimate tensile, but these are exceptions requiring careful process control.

Wrought aluminum spans a much wider range. Pure aluminum starts at just 90 MPa, but heat-treatable alloys climb to 690 MPa. The workhorse 6061-T6 alloy hits 310 MPa tensile and 240 MPa yield. The aerospace favorite 7075-T6 reaches 572 MPa tensile and 505 MPa yield—nearly double what you’d get from typical cast aluminum.

Ductility tells an equally important story. Cast aluminum stretches 1-5% before breaking. Wrought aluminum manages 10-25%. This difference determines whether your part fails gradually with warning or snaps suddenly under load.

Hardness ranges from 30-150 HB for cast aluminum. Wrought aluminum typically runs higher due to work hardening during mechanical processing. Both lose strength at elevated temperatures—cast aluminum’s hardness drops 34-66% by 500°C, with a steep transition starting at 220-238°C.

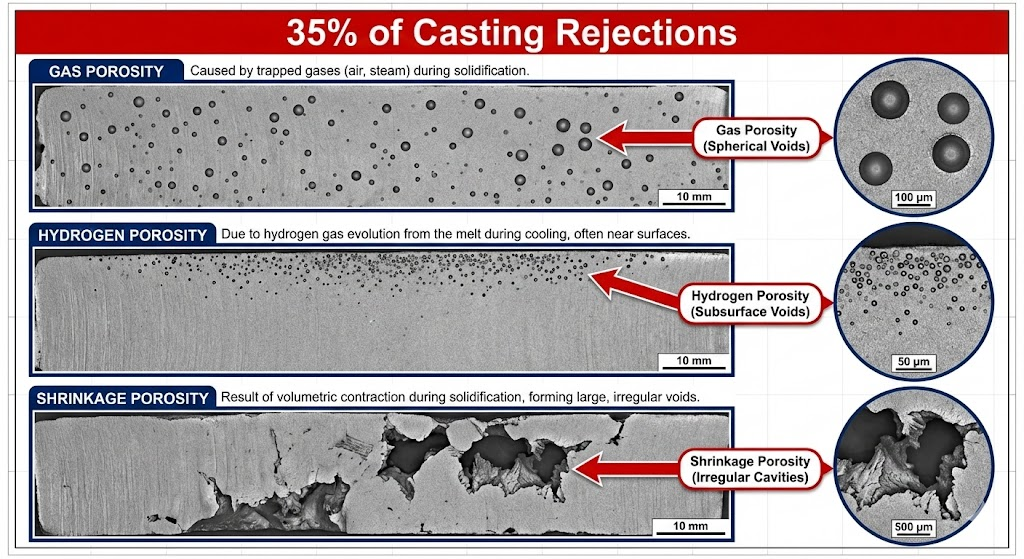

Porosity causes 35% of all casting rejections, according to the International Journal of Metalcasting. This single defect type costs manufacturers millions annually in scrapped parts, production delays, and quality holds.

Cast aluminum faces three porosity types:

Gas porosity forms when dissolved gas creates bubbles during cooling. Hydrogen porosity occurs because hydrogen dissolves in molten aluminum but not solid—creating voids as the metal solidifies. Shrinkage porosity creates jagged cavities during solidification.

Beyond porosity, you’ll encounter hot tears from thermal stresses, cold shuts where metal fronts don’t fuse properly, and dimensional warpage during cooling. These defects directly compromise mechanical performance and reliability.

Prevention requires tight process control. Keep casting temperature around 1375°F—higher temps double hydrogen entry every 100°F above 1400°F. Use rotary degassing with nitrogen to eliminate hydrogen. Design molds with proper venting channels to let trapped gases escape.

Wrought aluminum eliminates these casting defects entirely. You’re working with solid metal throughout processing. No opportunity for gas entrapment. No liquid-to-solid transition creating shrinkage voids.

The result? Superior structural integrity, better surface finishes, and more consistent tolerances. You pay more for wrought aluminum, but you’re buying defect-free internal structure.

The answer depends on what you’re trying to accomplish.

Cast aluminum’s biggest advantage is net-shape capability. You create complex geometries directly from the mold—internal channels, thin walls, ribs, and integrated mounting points that would require extensive machining if you started with wrought stock.

But internal defects complicate post-processing. Porosity creates unpredictable tool wear and surface finish problems. You can’t hold tight tolerances when the material contains voids. Sand casting achieves ±2mm tolerances. Die casting reaches ±0.1mm, but that’s as good as it gets.

Surface finish runs 200-560 RMS depending on your casting method. Sometimes that’s acceptable. Sometimes you need extensive machining to meet specifications.

Wrought aluminum excels at precision machining. No internal defects to interfere. Good dimensional accuracy for precision parts. Excellent for medical components requiring biocompatibility and stringent tolerances.

You’ll face five main challenges:

Long chip formation plagues pure and soft wrought aluminum. Chips stretch endlessly instead of breaking, tangling tools and requiring chipbreakers. High-strength alloys don’t have this problem.

Tool adhesion occurs because aluminum is soft and plastic. It sticks to tools, forming built-up edges. Overheat it, and you’re doing friction welding instead of machining.

Heat generation reduces machinability and tool life. Aluminum’s high thermal expansion coefficient means machining heat causes dimensional changes, reducing accuracy.

Built-up edge formation from low tensile strength leads to chip adhesion and smearing effects. You need proper tool selection, appropriate cutting speeds, and good coolant management to prevent this.

Friction stir welding outperforms traditional methods dramatically—97% efficiency versus 54% for MIG and 55% for TIG. If you’re joining wrought aluminum, FSW is the clear winner with 80% higher tensile strength than MIG or TIG welds.

There’s no universal “better” option. You need to match material properties to your specific requirements.

Choose cast aluminum when you need complex geometries that would cost too much to machine. Internal channels, thin walls, and integrated features come naturally from the mold.

The automotive industry relies heavily on cast aluminum. Engine blocks, cylinder heads, pistons, and transmission housings all benefit from casting’s design flexibility and cost-effectiveness at moderate production volumes.

Cast aluminum works best for low-to-medium production volumes where tooling costs distribute across enough parts to make economic sense. You’re looking at lower price per pound than wrought aluminum, though initial mold costs can be substantial.

Pick wrought aluminum when structural integrity is non-negotiable. Aerospace applications demand it—airframes, wing skins, fuselage panels, landing gear parts. You’re getting defect-free internal structure and superior mechanical properties.

The aerospace industry achieves roughly 10% aircraft weight reduction using lightweight wrought aluminum alloys. These savings directly translate to fuel efficiency and increased payload capacity.

Precision components requiring tight tolerances favor wrought aluminum. Medical devices, precision instruments, and high-performance automotive frames all benefit from wrought’s superior surface finish and dimensional accuracy.

Very high production volumes make wrought aluminum more economical despite higher processing costs. Think aluminum beverage cans—billions produced annually justify massive investments in rolling and forming equipment.

Cast aluminum excels at complex shapes and cost-effectiveness. Wrought aluminum delivers superior strength and precision. Neither is universally better.

Choose cast aluminum when design complexity, cost control, and moderate strength requirements align. Pick wrought aluminum when structural integrity, precision, and high mechanical performance are non-negotiable.

The numbers support both approaches. The global aluminum casting market reached $100.94 billion in 2024, growing at 4.9% annually. Meanwhile, wrought products dominate aluminum production at 85% of total volume.

Start with your application requirements. Assess strength needs, precision requirements, geometry complexity, and production volume. Evaluate cost constraints—initial investment versus per-unit costs versus total program costs. Consider quality needs for defect tolerance, surface finish, and dimensional accuracy.

Work with your aluminum supplier to validate your choice. Review material property tables for specific alloy grades. Match production volumes to manufacturing processes. Factor in environmental goals—cast aluminum typically contains 85% recycled content versus 0% for wrought.

The right material selection reduces defects, controls costs, and ensures reliable product performance. Get it right from the start, and you’ll avoid the costly mistakes that come from choosing the wrong aluminum type for your application.