Pure aluminum and cast aluminum differ primarily in their composition and manufacturing method. Pure aluminum contains 99% or more aluminum with minimal additives, while cast aluminum is an alloy that combines aluminum with other metals like silicon, copper, or magnesium to improve specific properties.

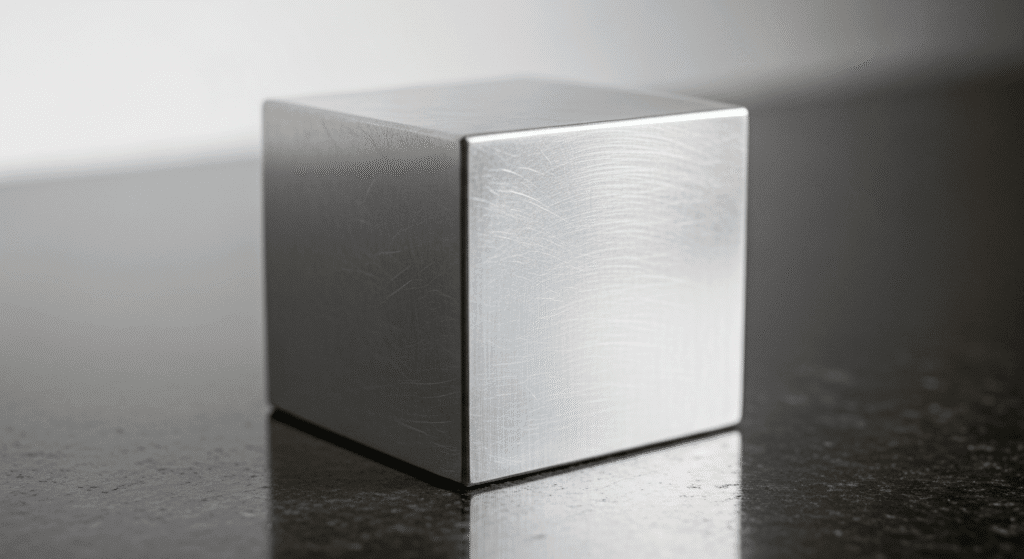

Pure aluminum is one of the most abundant metallic elements on Earth. It’s a soft, lightweight, silvery-white metal that you’ll find in everything from soda cans to power lines.

This metal naturally resists corrosion because it forms a thin oxide layer on its surface when exposed to air. That protective coating prevents further deterioration and keeps the metal looking clean.

Pure aluminum is highly conductive. It transfers both heat and electricity efficiently, which makes it perfect for electrical wiring and cookware.

However, pure aluminum has a significant drawback—it’s relatively weak. You can bend it easily with your hands, which limits its use in structural applications.

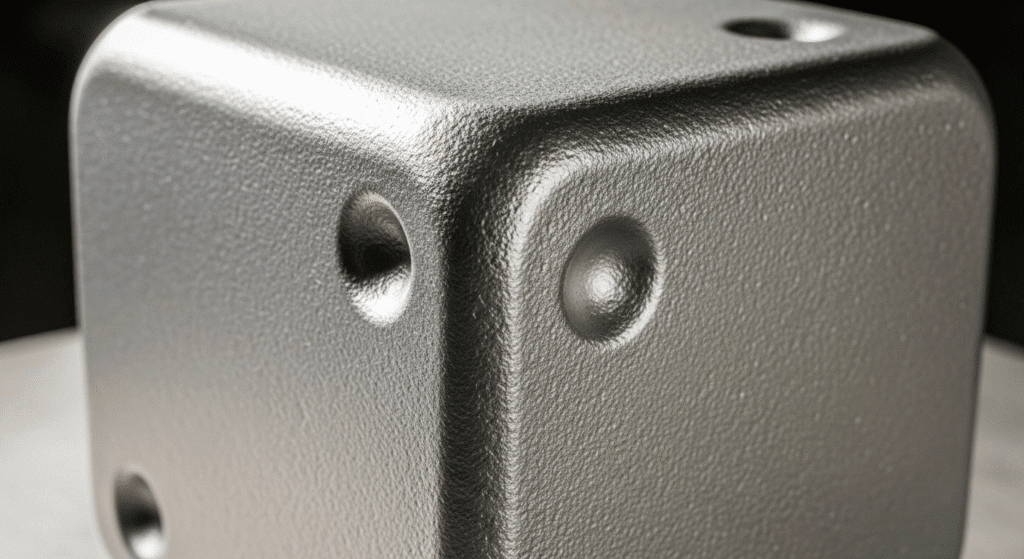

Cast aluminum is an alloy created by melting aluminum and mixing it with other metals during the casting process. Manufacturers pour this molten mixture into molds to create specific shapes and products.

The most common alloying elements include silicon (which improves fluidity and casting quality), copper (which increases strength), and magnesium (which enhances corrosion resistance). These additions transform aluminum from a soft, weak metal into a durable, workable material.

The casting process allows manufacturers to create complex shapes that would be difficult or impossible to machine from solid aluminum. This versatility makes cast aluminum incredibly popular in manufacturing.

Pure aluminum production involves extracting the metal from bauxite ore through electrolysis. Manufacturers refine the material to achieve 99% or higher purity, then roll, extrude, or draw it into sheets, bars, or wires.

Cast aluminum manufacturing starts with melting pure aluminum and adding specific alloying elements. Workers pour this molten mixture into sand molds, permanent molds, or die-cast molds. Once the metal solidifies, they remove the casting and clean it up.

Cast aluminum is significantly stronger than pure aluminum. The alloying elements create a harder, more rigid material that can withstand greater stress and impact.

Pure aluminum has a tensile strength of around 90 MPa (13,000 psi). It’s soft enough that you can scratch it with your fingernail.

Cast aluminum alloys can reach tensile strengths of 300 MPa (43,500 psi) or higher, depending on the specific alloy composition. That’s more than three times stronger than pure aluminum.

Both materials resist corrosion well, but they perform differently in various environments. Pure aluminum forms a natural oxide layer that protects it from atmospheric corrosion. This makes it excellent for outdoor applications in moderate climates.

Cast aluminum’s corrosion resistance depends on its alloying elements. Alloys with magnesium offer excellent corrosion resistance, even in saltwater environments. However, alloys with copper may be more susceptible to certain types of corrosion.

Cast aluminum is generally easier to machine than pure aluminum. The alloying elements make the material less gummy and sticky, which means cutting tools can work more efficiently.

Pure aluminum tends to cling to cutting tools and create long, stringy chips. This makes drilling, milling, and turning operations more difficult and time-consuming.

Pure aluminum is slightly lighter than most cast aluminum alloys. Pure aluminum has a density of about 2.70 g/cm³.

Cast aluminum alloys typically range from 2.65 to 2.85 g/cm³. The difference is usually only 2-5%.

Pure aluminum is generally less expensive than cast aluminum per pound of raw material. However, the total cost of a finished part depends on manufacturing complexity.

Cast aluminum parts often cost less to produce overall. The casting process can create complex shapes in one operation, eliminating expensive machining steps.

Pure aluminum products may require more processing—rolling, extrusion, cutting, and machining—which adds labor and equipment costs. These processing costs can exceed the initial material savings.

For mass production of complex parts, casting is usually the most economical choice. For simple shapes like sheets or bars, pure aluminum remains cost-effective.

Pure aluminum shines in applications where conductivity, formability, or maximum corrosion resistance matter most. You’ll find it in electrical wiring, capacitor foil, chemical equipment, food packaging, and decorative applications.

The food industry relies on pure aluminum because it’s non-toxic and doesn’t affect taste. Electrical applications use it because it conducts electricity efficiently.

Cast aluminum dominates applications requiring strength and complex shapes. Engine blocks, transmission housings, outdoor furniture, cookware, power tool bodies, and architectural components all use cast aluminum.

The automotive industry is cast aluminum’s biggest customer. Modern cars contain hundreds of pounds of cast aluminum in engines, wheels, and structural components.

Both materials have relatively low environmental impacts compared to other metals, but there are differences in their production and use.

Producing pure aluminum from bauxite ore is energy-intensive. The electrolysis process requires enormous amounts of electricity, which contributes to greenhouse gas emissions if the power comes from fossil fuels.

Cast aluminum often uses recycled aluminum as a base material, which reduces energy consumption by up to 95% compared to primary production. The casting process itself uses less energy than the refining process for pure aluminum.

Both materials contribute to sustainability because they’re infinitely recyclable without losing quality. However, cast aluminum’s ability to incorporate recycled content gives it an environmental edge in many applications.