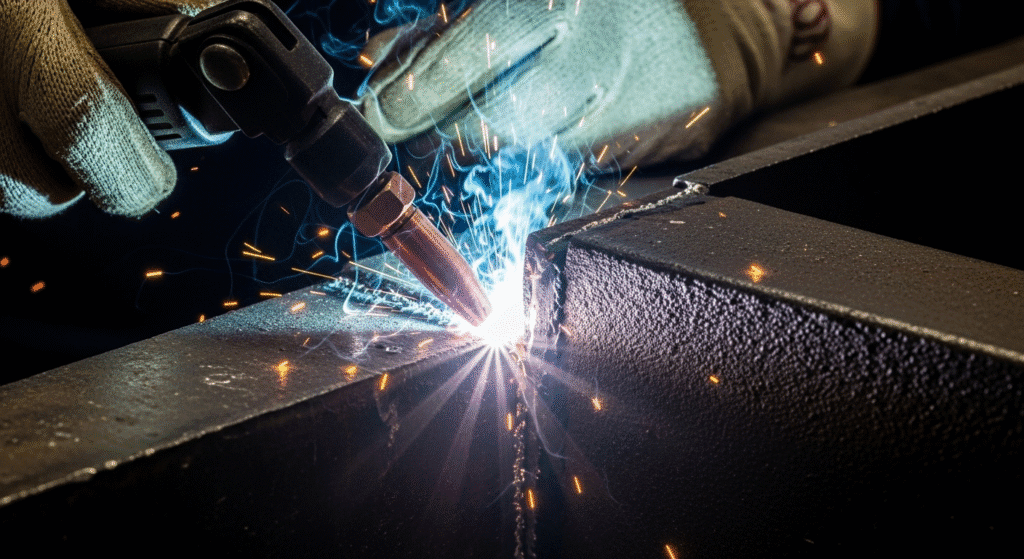

MIG welding cast iron is challenging but achievable when you use the right materials and techniques. The key to success lies in selecting proper filler wire, maintaining low heat input, and following a careful preparation process.

Cast iron’s high carbon content makes it brittle and prone to cracking during welding. You’ll need specialized nickel-based wires and specific temperature control methods to create strong, crack-free welds.

Each type has different carbon structures that affect how it responds to heat and welding.

Nickel-based wires are your best option for most cast iron repairs.

The right shielding gas protects your weld pool and improves arc stability when MIG welding cast iron. Your gas choice depends on the filler wire you’re using.

Remove all oil, grease, paint, and rust from the weld zone using a grinder or wire brush. Cast iron is porous and absorbs contaminants that will cause porosity if not removed completely.

Grind a V-groove at least 1/8 inch deep along the crack or joint. This ensures good penetration and removes any embedded contaminants.

Heat the entire workpiece to 500-600°F (260-315°C) using a propane torch or oven. Preheating reduces the cooling rate and minimizes thermal stress that causes cracking.

Check the temperature with a temperature-indicating crayon or infrared thermometer. Maintain this temperature throughout the welding process.

Set your welder to 18-22 volts and 80-120 amps for 1/8-inch thick material. Lower settings reduce heat input and prevent excessive melting of the base metal.

Use a wire feed speed of 150-250 inches per minute. Start with lower settings and adjust based on penetration and bead appearance.

Weld in short 1-2 inch beads, allowing each section to cool slightly between passes. This “skip welding” technique prevents heat buildup and reduces cracking risk.

Maintain a stick-out distance of 3/8 to 1/2 inch from the contact tip. This shorter distance provides better arc control on cast iron.

Immediately peen each weld bead with a ball-peen hammer while it’s still hot. Light peening relieves internal stress and helps prevent cracking as the weld cools.

Don’t peen too hard or you’ll damage the weld. Apply moderate taps across the entire bead surface.

Bury the welded part in sand, lime, or vermiculite to slow cooling. Slow cooling over 24-48 hours prevents the formation of brittle, crack-prone structures.

For large parts that can’t be buried, cover with insulation blankets. Keep the part above 200°F for at least 2 hours after welding.

Check for cracks using dye penetrant or visual inspection after complete cooling. Small surface cracks can often be ground out and rewelded.

Grind the weld smooth if appearance matters. Nickel welds machine beautifully, while steel welds on cast iron are harder to finish.

Yes, but only for small repairs using high-nickel electrodes. The nickel stays soft and stretches to accommodate stress, reducing crack risk even without preheating.

Using too much heat is the most common error. Excessive heat causes the cast iron to crack during cooling, ruining the repair.

Cast iron cracks because rapid cooling creates brittle martensite in the heat-affected zone. This hard, inflexible structure can’t handle welding stress.

Stick welding with nickel rods is generally easier for beginners on cast iron. MIG welding works well but requires more precise heat control and proper wire selection.

Yes, you can join cast iron to steel using nickel-based or stainless steel filler materials. Preheat both materials and use the lowest heat input possible.

Perform a spark test—gray and ductile iron produce short, red sparks that indicate weldability. White cast iron creates long, white sparks and shouldn’t be welded.