Sand casting is an industrial process where molten metal pours into a mold made from sand and binders, then cools to form the finished part. The metal you choose directly affects your part’s strength, cost, weight, and ability to resist corrosion or heat.

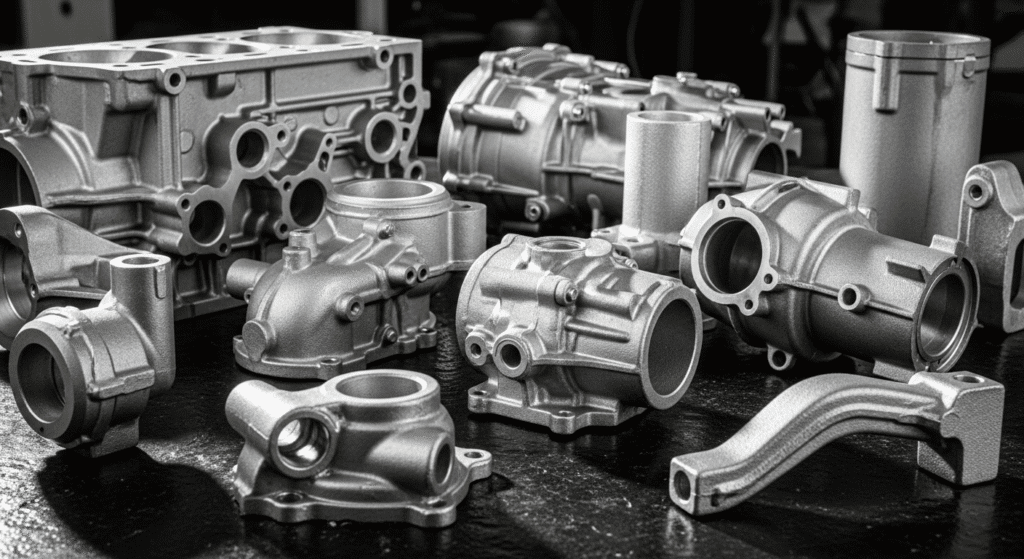

Industries use sand casting to manufacture everything from automotive engine blocks to aerospace components to industrial pump housings. The process works with nearly any metal alloy, from lightweight aluminum to high-strength steel to specialized stainless options.

Sand casting divides metals into two main categories: ferrous metals (iron and steel) and non-ferrous metals (aluminum, brass, bronze, and stainless steel). Ferrous metals offer high strength at lower cost. Non-ferrous metals provide lightweight options, better corrosion resistance, and superior castability.

Aluminum is the most popular sand casting metal for industrial applications because it combines lightweight design with excellent castability and competitive pricing. A single aluminum part can weigh 70% less than an equivalent iron part while delivering comparable strength.

The most common aluminum sand casting alloy is A356, used in industries ranging from automotive to aerospace. A356 contains 7% silicon, which improves fluidity during casting and reduces shrinkage defects. This composition makes A356 ideal for complex parts that require tight dimensional tolerances.

Cast iron is the backbone of industrial manufacturing because it offers unbeatable cost, proven reliability, and strength in compression. Gray iron and ductile iron dominate sand casting applications across automotive, machinery, and heavy equipment industries.

Gray iron earned its name from the gray color visible on a fractured surface. This gray appearance comes from graphite flakes that form during cooling. Those graphite flakes dampen vibration excellently, which is why machinery bases and engine blocks traditionally use gray iron.

Steel castings deliver the highest tensile strength of any common casting metal, making them essential for applications where loads are extreme or failure is not an option. Steel combines high strength with excellent ductility—the ability to bend without breaking—under stress.

Steel melts at 1,370-1,510°C, requiring specialized foundry equipment and precise temperature control. The higher melting temperature means increased energy consumption, translating to steel castings that cost 50-100% more than iron or aluminum alternatives.

Brass and bronze are copper-based alloys selected for applications where corrosion resistance matters more than low cost. These materials shine in marine environments, chemical processing, and applications requiring antimicrobial properties.

Brass combines copper with zinc (typically 60-90% copper, 10-40% zinc). Bronze combines copper with tin or other elements. Both metals develop a protective patina on the surface that prevents further corrosion, enabling them to last decades in harsh environments.

Stainless steel combines iron’s strength with chromium’s corrosion resistance, creating an alloy that handles both chemical attack and high temperatures. Industrial applications requiring food contact, chemical containment, or high-temperature service rely on stainless steel castings.

Stainless steel melts at approximately 1,400°C, requiring sophisticated foundry capabilities. Common stainless grades for sand casting include 304 (CF8), 316 (CF8M), and 410 (CA15).

Choosing the right casting metal begins with understanding your part’s requirements: mechanical loads, environmental conditions, production volume, and budget constraints. A systematic evaluation across these factors identifies the optimal material.

| Metal | Melting Temperature | Castability | Tensile Strength | Cost per kg | Best For |

|---|---|---|---|---|---|

| Aluminum A356 | 660°C | Excellent | 200-350 MPa | $0.10-$0.25 | Lightweight, complex parts; automotive, aerospace |

| Gray Iron | 1,150°C | Very Good | 150-350 MPa | $0.15-$0.25 | Machinery bases, high-volume production |

| Ductile Iron | 1,150°C | Good | 350-600 MPa | $0.18-$0.30 | Heavy machinery, impact-resistant parts |

| Carbon Steel | 1,370°C | Good | 400-800 MPa | $0.30-$0.50 | High-strength, critical components |

| Brass/Bronze | 900°C | Excellent | 250-400 MPa | $0.80-$2.00 | Marine, corrosion-resistant applications |

| Stainless Steel 304 | 1,400°C | Fair | 300-500 MPa | $1.50-$3.00 | Chemical resistance, food processing |

Engine blocks and cylinder heads cast from gray iron dominate traditional vehicle production due to proven reliability and lowest cost. Modern lightweight engines increasingly substitute aluminum A356 for improved fuel efficiency.

Transmission cases, valve bodies, and fluid manifolds use ductile iron when strength matters, aluminum when weight reduction is the priority. High-performance engines may employ steel castings for turbocharger housings and supercharger rotors.

Jet engine housings and turbine shrouds cast from steel or specialized nickel-based alloys withstand extreme temperatures and mechanical stress. Aluminum castings serve for compressor housings, structural brackets, and hydraulic fittings where weight reduction improves aircraft performance.

Helicopter rotor hubs, landing gear support structures, and wing attachment points frequently use ductile iron for its combination of strength, reliability, and proven track record in safety-critical applications.

Pump housings and impellers cast from brass or bronze handle corrosive fluids in chemical plants and water treatment facilities. Gray iron pump bases support the machinery while damping vibration.

Machinery bases, motor mounts, and structural frames traditionally use gray iron due to its exceptional vibration damping and lowest cost. Precision machinery sometimes substitutes ductile iron to reduce base thickness while maintaining stiffness.

Valve bodies for process control cast from stainless steel in chemical plants and from brass in marine applications. Safety valve housings frequently employ steel to withstand extreme pressure without failure.

Bucket teeth, excavator arm castings, and crusher jaw plates endure abrasion and impact in mining operations. Gray iron provides the traditional solution; ductile iron improves reliability in high-stress applications; steel enables smaller, lighter designs.

Bulldozer track sections, bucket linkages, and hydraulic cylinder end caps cast from ductile iron combine strength with ductility, preventing catastrophic failure under the extreme loads these machines experience.

Plow shares and cultivator components cast from ductile iron or steel resist soil abrasion and impact from hidden rocks. The damping properties of gray iron make it suitable for tractor engine blocks and gearbox housings.

Aluminum A356 is the beginner-friendly choice because it melts at the lowest temperature (660°C), requires simple equipment, and produces quality parts with minimal defects. Many hobbyist and small foundries specialize in aluminum castings, making expertise and support readily available.

No. Sand casting requires a single metal pour into one mold. You cannot combine aluminum and steel in a single pour because they have drastically different melting temperatures and chemical properties. Two-material assemblies require separate castings that are welded or bolted together afterward.

Gray iron costs less and damps vibration excellently but is brittle (poor tensile strength). Ductile iron costs 10-15% more but provides 50-80% higher tensile strength and can flex slightly without breaking. Choose gray iron for stationary, low-stress applications; choose ductile iron when parts experience impact, high loads, or failure would create downtime.

Choose specialty metals only when standard materials will visibly fail in your specific environment. Stainless steel in a dry industrial setting is wasteful and expensive. Nickel-aluminum bronze for a freshwater dam would be similarly impractical. Specialty metals justify their cost only when they demonstrably extend equipment lifespan or prevent catastrophic failure in harsh environments. Always start with standard metals and upgrade only when proven necessary.