The casting method you choose determines your part’s cost, quality timeline, and whether it’ll perform reliably in the field. You’re not just picking a process – you’re picking a set of trade-offs that ripple through your entire project.

Here’s the challenge: many manufacturers struggle to choose between green sand casting, the proven workhorse of the foundry industry, and no-bake casting, which delivers precision and consistency at a higher price. Both processes work. Both are widely used. But they excel in completely different scenarios.

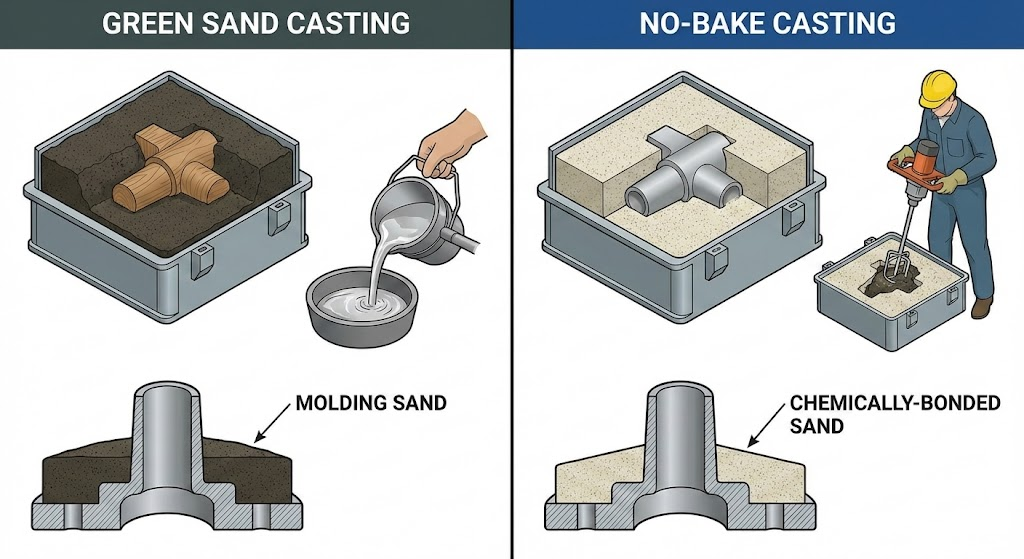

Green sand casting is the world’s most widely used molding process, and it’s been around for decades because it works. The term “green” doesn’t mean environmentally friendly – it means the sand is uncured and still wet, like green wood.

Here’s how it works: you pack a mixture of silica sand, bentonite clay, water, and additives around a pattern (your part’s shape). You ram the sand firmly to create mold strength. Once the pattern is pulled out, you’ve got a cavity ready for molten metal. You pour the hot metal in, let it cool, and extract your finished casting.

The beauty of green sand is simplicity. The materials are cheap, abundant, and recyclable. Foundries can recycle the same sand dozens of times by adjusting the moisture and clay content. This makes green sand the most economical choice for large production volumes and simple to moderately complex parts.

No-bake casting, also called air-set casting, works on a completely different principle. Instead of relying on clay and moisture for mold strength, it uses a chemical binder system – typically urethane or furan resin mixed with a catalyst.

Here’s the process: you mix kiln-dried sand with chemical binders and a catalyst. Unlike green sand, there’s no moisture involved. The sand mixture sets at room temperature through a chemical reaction that hardens the mold into what foundries call a “brick-like” product.

Because the mold is chemically bonded rather than held together by moisture, it’s dramatically more rigid. This rigidity translates to better dimensional stability, tighter tolerances, and fewer defects when the molten metal hits the mold. The trade-off is cost – the chemical binders are expensive, and the curing time (typically several hours at room temperature) is longer than green sand’s rapid mold production.

Let’s talk money, because this often drives the decision.

Raw Material Costs

Green sand production costs about $0.10 to $0.25 per kilogram of finished casting. The materials themselves are dirt cheap – literally. Silica sand costs a few dollars per ton. Bentonite clay adds minimal cost. Water is free.

No-bake castings cost more upfront. The chemical binders add significant material expense. You’ll typically pay 30-50% more for the raw materials in a no-bake mold compared to green sand.

Total Production Cost Including Machining

Here’s where things get interesting: the real cost difference often disappears when you factor in machining.

Green sand castings typically come out of the mold with surface finish of Ra 6-12 micrometers – rough by modern standards. This means you’ll often need to machine surfaces to reach your final specifications. That machining time adds up fast, especially on large production runs.

No-bake castings achieve surface finishes of Ra 3-6 micrometers straight from the mold. You need less machining, sometimes none at all. A foundry doing a comparison study found that when they added machining costs to the equation, an alpha-set no-bake system actually cost less than traditional green sand for medium-sized castings in grey cast iron.

When Each Wins

Choose green sand for high-volume production of simple parts where you don’t mind the machining work – think engine blocks in the thousands.

Choose no-bake when your part demands tight tolerances or complex geometry, or when the volume is small enough that machining costs really hurt.

The rigidity difference between these two processes shows up in measurable ways.

Dimensional Tolerances

Green sand molds achieve ISO tolerance class CT11 to CT14, which translates to roughly ±0.5% to ±2.0% of any given dimension. For a 100-millimeter feature, you might see ±1 to ±2 millimeters of variation.

No-bake molds tighten that to CT9 to CT12 – about ±0.3% to ±1.2%. That same 100-millimeter feature might vary only ±0.3 to ±1.2 millimeters.

It’s not a game-changer for all applications, but it matters when your part fits into a tight assembly or when high precision affects performance.

Surface Finish

Green sand produces surface finishes of Ra 6-12 micrometers. That’s visible roughness you can feel with your hand. Most parts need secondary finishing to meet modern surface requirements.

No-bake delivers Ra 3-6 micrometers – smooth enough to skip finishing operations on many parts. This alone can save weeks if you’re outsourcing machine work.

Defect Rates

Green sand’s biggest weakness is gas porosity – tiny air bubbles trapped inside the casting. Why? The moisture in the mold evaporates when hot metal hits it. If that water vapor can’t escape fast enough, it gets trapped in the cooling metal as porosity.

You also see shrinkage defects more often in green sand because the mold’s flexibility allows it to sag or shift slightly as metal cools and shrinks. Combined with moisture issues, this is why green sand produces more internal voids and surface irregularities.

No-bake molds stay rock-solid because they’re chemically bonded. The mold doesn’t flex or move as the metal cools. Gas porosity drops dramatically because the chemical binder systems produce less gas compared to moisture-laden molds. The result: no-bake castings are more likely to be defect-free the first time.

If you need 500 molds per hour, green sand is your answer. Mechanized green sand lines can produce moulds at incredible speed – pattern removal, sand ramming, and flask handling all happen in seconds.

No-bake lines produce 20-30 molds per hour. That’s not slow in absolute terms, but it’s a 10-15x difference. The limiting factor is the chemical cure time – you can’t pour metal until the binder has set, which takes hours even at room temperature.

For high-volume commodity castings, green sand wins on speed every time. For smaller batches or highly engineered parts, the speed difference doesn’t matter – you’re not running the mold line flat-out anyway.

Green sand dominates these sectors:

Automotive produces engine blocks, cylinder heads, transmission cases, and brake drums in green sand. The sheer volume makes the cost advantage critical.

Agriculture depends on green sand for tractor parts, plow bases, and heavy equipment. These parts don’t demand pristine surface finishes, just durability.

Construction machinery like excavator buckets and bulldozer parts come from green sand because volume and cost matter more than precision.

No-bake finds its home in:

Aerospace uses no-bake for turbine housings, compressor impellers, and engine mounts. Defect-free performance at high temperatures isn’t negotiable.

Defense applications like gun breaches and missile components need no-bake’s consistency and defect control.

Medical devices and precision instruments require dimensional accuracy that green sand simply can’t deliver reliably.

Heavy industrial machinery for oil and gas, chemical processing, and power generation often chooses no-bake for mission-critical valve bodies and pump housings where failure could mean shutdowns costing hundreds of thousands per day.

Step 1: Define your tolerance and surface finish requirements. Pull out your drawings and ask: what dimensions need to hold tight? What surfaces need to be smooth? If you’re seeing tolerances tighter than ±1%, or surface finishes better than Ra 6, no-bake is your path.

Step 2: Calculate total cost including machining. Get quotes from both a green sand and no-bake foundry for the same part. Add your estimated machine shop costs for secondary finishing. You might be surprised which one actually costs less.

Step 3: Evaluate production volume. Are you making 10 parts or 10,000? Green sand’s speed advantage only matters if you’re running high volume. For 50 or 100 parts, the setup time difference becomes irrelevant.

Step 4: Assess part complexity and wall thickness. Complex geometries with thin walls tend to favor no-bake because its rigid mold resists distortion better as metal flows and cools.

Step 5: Consider long-term repeatability. If you’re building parts that need to be identical month after month, no-bake’s consistency beats green sand’s natural variation. That matters for customer satisfaction and field performance.

Green sand casting is your answer when you’re prioritizing cost and speed, especially for high-volume runs of simple to moderately complex parts. It’s the proven, economical choice that’s powered manufacturing for a century.

No-bake casting wins when precision, consistency, and defect-free performance matter more than lowest-first-cost. You pay more upfront, but you get tighter tolerances, better surface finishes, and fewer casting defects right out of the mold.

The “right” choice isn’t about which process is better – it’s about which one solves your specific problem. Talk with your foundry partner about your exact requirements, and let them help you decide. They’ll know which process gives you the best value for your unique application.