Engineers often specify surface finish requirements without knowing what sand casting can actually achieve. A designer grabs a typical limit like 125 RMS or 63 Ra without specifying where on the casting, how to inspect it, or whether that finish is even necessary. The result is over-specification that adds cost without adding value.

Sand casting surface finish ranges from Ra 1.6 um with shell molding to Ra 25+ um with green sand. Knowing these ranges by sand type lets you specify realistically and choose cost-effective improvement methods when smoother surfaces are needed.

Surface finish varies dramatically depending on the moulding sand used. Green sand produces the roughest surfaces, while shell molding approaches investment casting quality.

| Sand Type | Ra Value (um) | RMS (microinches) | Relative Cost |

|---|---|---|---|

| Green sand (manual) | >25 | 500-900 | Lowest |

| Green sand (automatic) | >25 | 250-500 | Low |

| Resin-bonded (no-bake) | 6.3 | 150-600 | Moderate |

| Resin-bonded (fine) | 3-6 | 75-150 | Moderate-High |

| Shell mold (typical) | 3.2 | 75-150 | Higher |

| Shell mold (optimized) | 1.6-3.2 | 63-125 | Higher |

| Oil-bonded (Petrobond) | 6-12 | 150-300 | Moderate |

For context, investment casting typically achieves Ra 0.8-2.0 um (60-80 RMS), and die casting reaches Ra 0.5-1.5 um.

Small foundry operators switching from green sand to oil-bonded sand like Petrobond report immediate improvement in surface quality. The tradeoff is material cost and different handling characteristics, but for prototype work or short runs where finish matters, the switch often pays for itself in reduced post-processing.

Three primary factors determine as-cast surface finish: grain size, grain shape, and mold coating.

Grain Size and the GFN Threshold

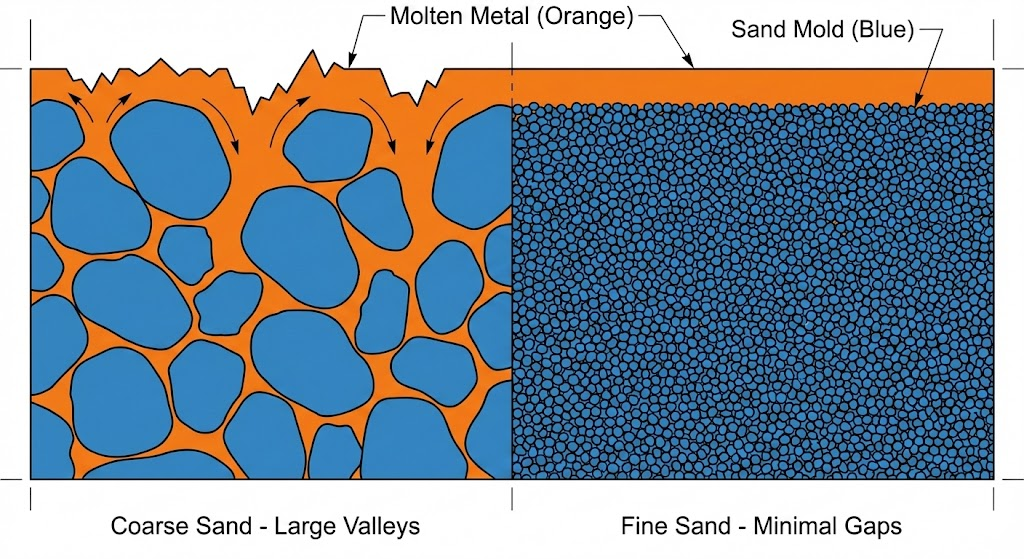

Finer sand grains produce smoother surfaces because molten metal has smaller gaps to flow into. Think of sand grains as creating peaks and valleys on the mold surface. Larger grains mean deeper valleys, which the metal fills, creating rougher castings.

University of Northern Iowa research identified threshold GFN (Grain Fineness Number) values beyond which finer sand provides no additional improvement:

| Sand Material | Threshold GFN | Best Achievable RMS |

|---|---|---|

| Silica | 67 | 185 |

| Zircon | – | 200 |

| Chromite | 77 | 250 |

| Olivine | 84 | 244 |

| Ceramic | – | 236 |

Going finer than these thresholds wastes money on premium sand without improving surface quality. For silica sand, 67 GFN delivers the best achievable surface. Specifying 100 GFN silica adds cost with no finish benefit.

Grain Shape

Spherical and round grains improve surface finish at an accelerated rate compared to angular grains. However, the research shows that any particle shape can achieve similar ultimate finish quality. Round grains just get there faster with coarser sand sizes.

The practical implication: if you need Ra 6.3 um, you can achieve it with either round fine sand or angular very-fine sand. Round sand costs more but may improve mold permeability.

Mold Coatings

Refractory coatings applied to mold surfaces can dramatically improve finish, especially on rough substrates. Research on 3D printed sand molds showed coatings improved surface finish from 943 RMS (uncoated) to 339-488 RMS (coated). That is a 48-64% improvement.

The coating creates a thermal barrier between metal and sand, reducing metal penetration into sand gaps. Importantly, coating effectiveness is somewhat independent of substrate roughness. Even molds made from coarse sand benefit significantly from proper coating.

When as-cast finish does not meet requirements, you have two options: improve the mold or finish the casting after pouring.

Mold-side improvements affect every casting from that mold, making them cost-effective for production runs.

Sand Selection: Moving from green sand (Ra >25 um) to resin-bonded sand (Ra 6.3 um) provides roughly 75% improvement in surface quality. For critical surfaces, shell molding (Ra 1.6-3.2 um) approaches investment casting finish.

Grain Size Optimization: Use the GFN threshold values to select optimal sand. For silica, 67 GFN delivers maximum smoothness. Going finer wastes budget.

Mold Coating: Apply refractory coatings to mold surfaces. One automotive manufacturer combined sand selection, vibratory compaction, and pattern optimization to reduce surface roughness by 40%.

Pattern Quality: High-precision patterns with proper finish transfer directly to mold quality. 3D printed patterns with smooth surfaces improve final casting finish.

Post-casting finishing adds cost per piece but enables smoother surfaces than any sand casting process can achieve as-cast.

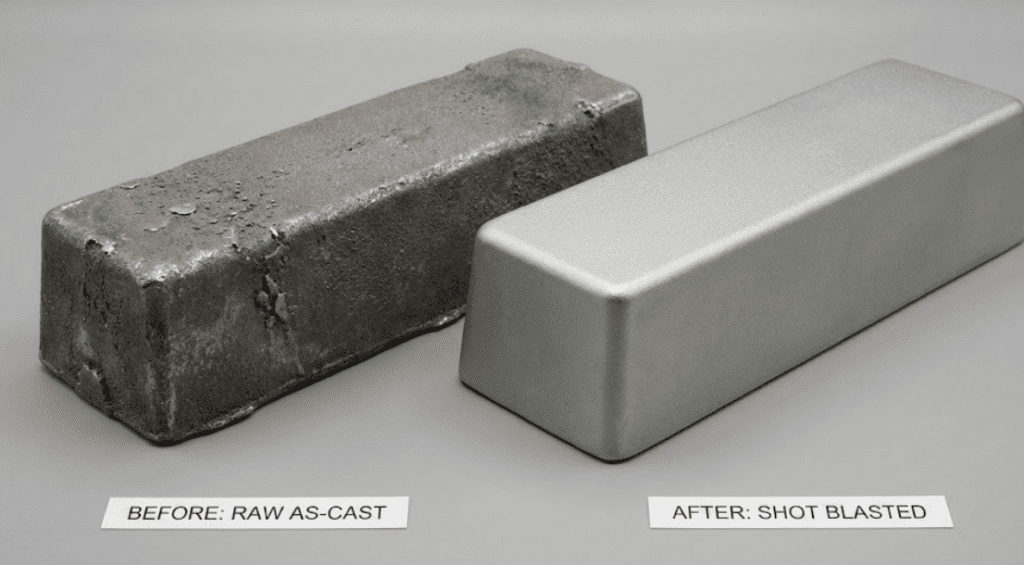

Shot Blasting: Steel shot removes scale and provides uniform matte finish. Typical life is 150 cycles before media replacement. Does not significantly reduce Ra values but improves uniformity.

Vibratory Tumbling: Effective for bulk finishing of smaller castings. Can improve finish from 75+ RMS to below 35 RMS for suitable part geometries.

Grinding and Machining: The only way to achieve Ra values below 3.2 um on sand castings. Required for sealing surfaces, bearing journals, and precision mating surfaces. Plan for 2-5 mm machining allowance on sand castings (compared to 0.5 mm for die castings).

Chemical Treatments: Acid etching and passivation improve appearance and corrosion resistance but provide minimal Ra improvement.

Before specifying any surface finish requirement, ask whether you actually need one. If the surface does not involve squeaks, leaks, friction, wear, appearance, or adhesion, perhaps no surface texture requirement is necessary.

When to Specify Machining

| Application | Required Ra | Recommendation |

|---|---|---|

| Bearing surfaces | 0.8-1.6 um | Always machine |

| Hydraulic valve seats | 0.8 um | Always machine |

| Sealing surfaces | 1.6-3.2 um | Machine or shell mold |

| Gear teeth | 1.6-3.2 um | Machine |

| General brackets | 12.5-25 um | As-cast acceptable |

| Structural covers | 12.5+ um | As-cast acceptable |

When As-Cast Finish Suffices

Most structural components, brackets, housings, and covers function perfectly with as-cast finish. Specifying Ra 6.3 um on a motor housing cover that gets painted adds machining cost with no functional benefit.

Machining Allowance

When machining is required, design with adequate stock:

Undersized allowance risks exposing subsurface porosity. Oversized allowance wastes material and machining time.

Inspection Method

As-cast surfaces should be inspected by visual and tactile comparison to AFS or other surface finishing standards, not profilometer measurement. Profilometer readings on as-cast surfaces are inconsistent due to the random, non-directional nature of cast surface texture. Reserve profilometer inspection for machined surfaces.

Surface finish specification starts with a functional question, not a number. If your surface does not need to seal, mate, or resist wear, an as-cast finish from appropriate sand selection may be all you need.

When smoother surfaces are required, match the method to the requirement. Shell molding achieves Ra 1.6-3.2 um without post-processing. Mold coatings provide 40-60% improvement on any sand type. Machining is the only path to Ra below 1.6 um but requires 2-5 mm stock allowance.

Process selection affects total cost more than unit price. A resin-bonded casting that meets spec as-cast often costs less than a green sand casting plus machining, even when the per-piece sand cost is higher.