When automotive manufacturers switched from cast iron to aluminum engine blocks, they achieved 40-55% weight reduction. That single change demonstrates why aluminum sand casting has become the go-to process for industrial applications where weight matters.

This guide covers the mechanics behind aluminum’s weight advantage, key specifications you need to know, and a framework for deciding when sand casting makes sense for your project.

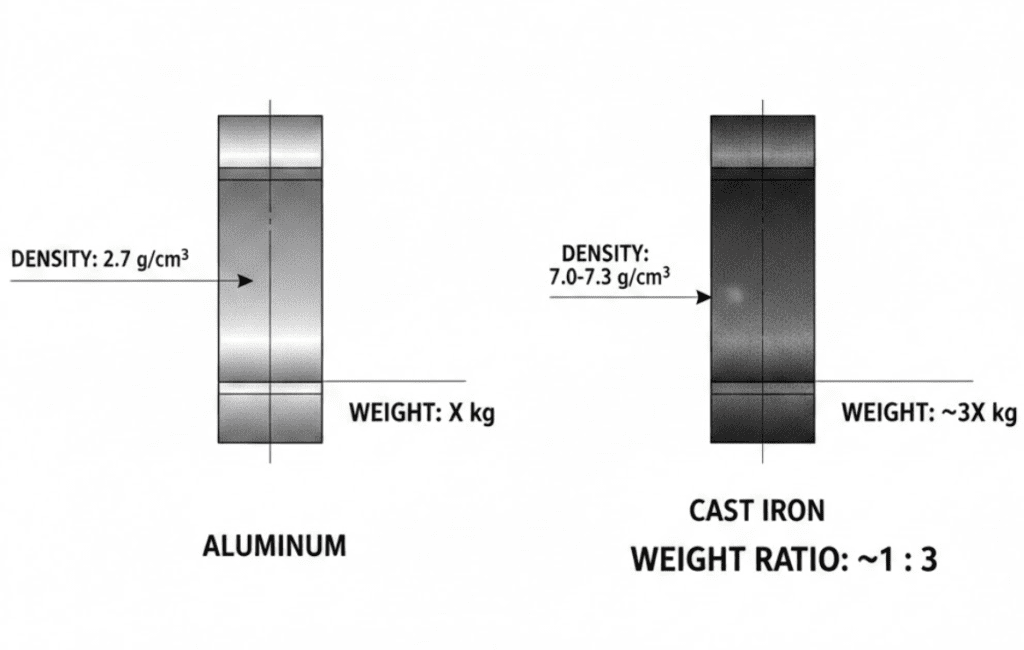

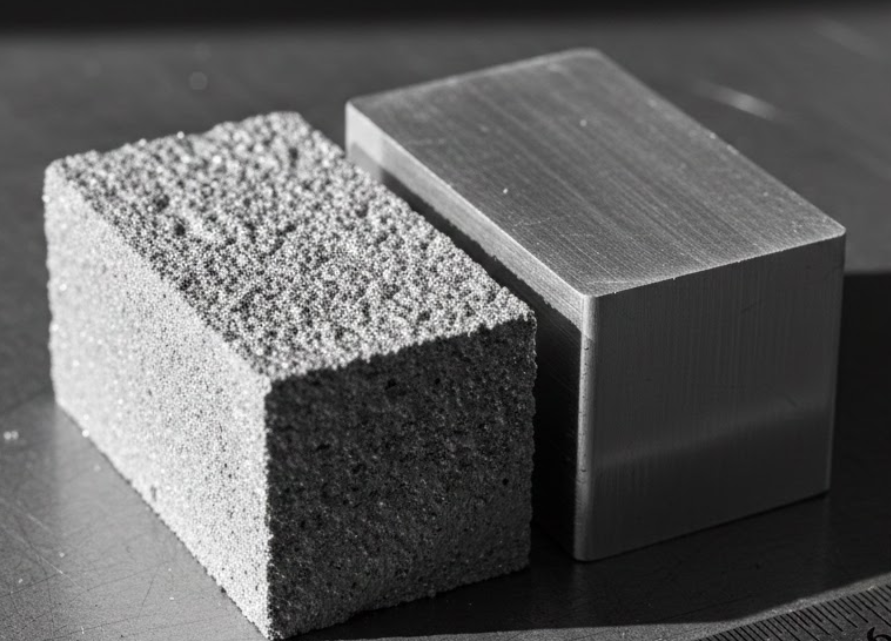

The weight advantage comes down to density. Aluminum measures 2.7 g/cm3 compared to cast iron at 7.0-7.3 g/cm3 and steel at 7.85 g/cm3. For identical geometry, an aluminum casting weighs roughly one-third of its iron or steel equivalent.

But raw density only tells part of the story. Aluminum’s lower absolute strength means designs often require thicker walls to match load requirements. Even accounting for this, finished cast aluminum parts typically achieve 30-40% weight savings versus ferrous alternatives.

From a sourcing perspective, weight savings translate directly to operational benefits. In transportation applications, every 10% reduction in vehicle weight yields 6-8% improvement in fuel efficiency. For handling and installation, lighter castings reduce crane requirements and simplify assembly.

The thermal properties add another dimension. Aluminum conducts heat three times faster than cast iron, making it preferred for heat exchangers, motor housings, and any application where thermal management matters.

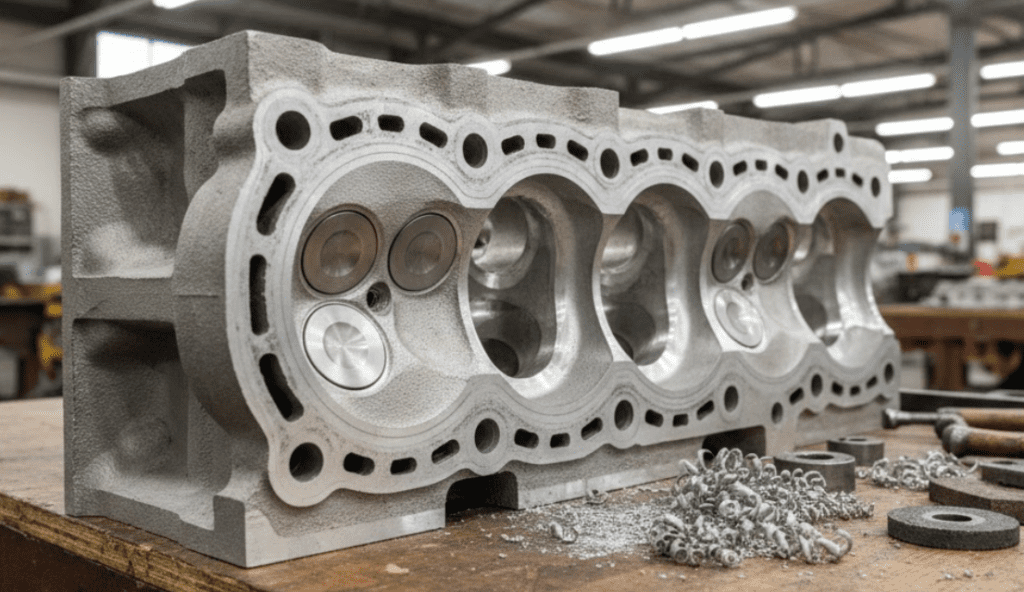

The automotive sector drives aluminum sand casting adoption. Approximately 75% of cylinder heads and 85% of intake manifolds now use aluminum castings. Engine blocks alone account for 3-4% of total vehicle weight, making them prime targets for lightweighting.

Transmission cases, oil pans, and structural brackets increasingly specify aluminum sand castings as well. The combination of weight savings and design flexibility suits the automotive industry’s shift toward fuel efficiency and electrification.

Industrial applications often prioritize different factors. A recent case study illustrates the capability: a food processing equipment manufacturer required a 32 x 18 x 66 inch A356 aluminum mold for plastic container production. The sand casting achieved surface finish below 250 RMS with porosity under 0.8%—specifications that met demanding quality requirements while keeping tooling costs manageable.

Pump housings, valve bodies, gear housings, and machine bases commonly use aluminum sand castings. The process handles the complex internal passages these components require without prohibitive tooling investments.

Aerospace applications demand the tightest specifications. Here, weight savings carry premium value—every kilogram removed improves payload capacity or fuel range. Aluminum sand castings serve structural components, housings, and fixtures where complex geometry makes other processes impractical.

Defense applications similarly prioritize the weight-to-strength ratio for portable equipment and vehicle components.

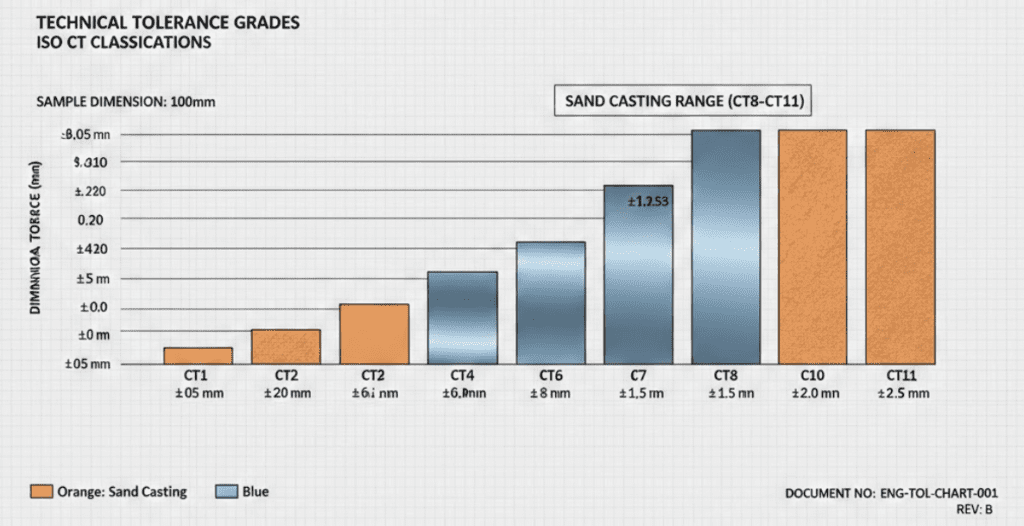

Sand casting produces parts in the ISO CT8-CT11 tolerance range. In practical terms, expect +/-0.125 in (+/-3 mm) or +/-2% of the nominal dimension, whichever is greater. Refined processes can achieve +/-0.06 in on small-to-medium castings under 12 inches.

For comparison, die casting achieves CT1-CT4 tolerances (+/-0.05-0.3% of dimension). When your design requires tighter tolerances, factor in secondary machining costs. Standard machine stock allowance runs 0.045-0.060 in for dimensions up to 6 inches.

The industry references ASTM B26/B26M for aluminum sand casting specifications. For critical applications, ASTM B686/B686M covers high-strength requirements typical in aerospace.

Aluminum sand castings typically produce 300-560 RMS surface finish as-cast. This suits many structural and functional applications directly. Cosmetic surfaces or sealing faces generally require machining.

Die casting delivers 20-120 RMS for comparison. If your application demands as-cast smooth surfaces throughout, die casting may justify the higher tooling cost.

Two alloys dominate aluminum sand casting: A356 and 319.

A356 (T6 heat treated) delivers tensile strength of 230-255 MPa and yield strength of 165-186 MPa. It offers superior fluidity for intricate details and better elongation (3.5-5%). Specify A356 for structural applications, aerospace parts, or designs with thin sections requiring complete mold fill.

319 achieves lower strength—tensile around 160-215 MPa depending on heat treatment—but provides better weldability and costs less. It suits engine components, general industrial parts, and applications where pressure tightness matters more than maximum strength.

Minimum wall thickness for sand castings runs 0.180 in for permanent mold processes. Isolated thick sections require risers to prevent shrinkage porosity—a design consideration your foundry partner should address during pattern review.

Process selection depends on volume, tolerance requirements, and total cost of ownership—not just unit price.

Tooling costs tell the initial story:

Per-part costs shift the equation at volume:

Break-even falls around 850-1,500 parts. Below that threshold, sand casting wins on total cost. Above it, die casting’s lower per-part cost eventually overcomes tooling amortization.

But volume alone oversimplifies the decision. Consider these factors:

Choose sand casting when:

Consider die casting instead when:

When aluminum may not be appropriate:

The total cost of ownership includes qualification testing, secondary machining, and scrap rates. Sand casting typically shows lower qualification costs but higher machining requirements. Die casting inverts that relationship.

When requesting quotes for aluminum sand castings, specify:

Start with the decision framework: if annual volume falls under 1,000 parts and tolerances permit machining, sand casting likely delivers the lowest total cost. Above 1,500 units with tight tolerances, run the numbers on die casting—the tooling investment may pay back faster than expected.

For most industrial applications, aluminum sand casting provides the practical balance of weight savings, design flexibility, and cost control that makes it the workhorse process for lightweight parts.