Yes, you absolutely can do sand casting at home with basic tools, the right materials, and proper safety equipment. Thousands of hobbyists successfully cast aluminum, brass, and other metals in their garages and backyards using this ancient technique that’s been around for over 5,000 years.

Sand casting is essentially making a mold out of special sand, pouring molten metal into it, and letting it cool to create your desired shape. Think of it like making sandcastles at the beach, except you’re creating a hollow space that you’ll fill with liquid metal instead of just shaping the sand itself.

You’ll need five essential components:

A basic setup costs between $200-500 if you buy everything new. You can reduce costs significantly by building your own furnace from a steel bucket and refractory cement, or by starting with lower-melting metals like aluminum from recycled cans.

The most popular starter metal is aluminum because it melts at just 1,221°F (660°C), which you can achieve with a simple propane torch setup. Compare that to iron, which needs temperatures over 2,800°F—way beyond what most home setups can handle.

Mix 10 parts fine silica sand with 1 part bentonite clay (cat litter works in a pinch). Add just enough water to make it hold together when you squeeze it—about 3-5% moisture content.

The consistency should be like damp beach sand that holds its shape. Too wet and you’ll get steam explosions; too dry and your mold will crumble.

Your pattern is the object you want to copy in metal. You can use wood, 3D printed plastic, or even existing metal objects as patterns.

The pattern needs to be slightly larger than your final piece because metal shrinks as it cools—about 1-2% for aluminum. If you’re making something that needs to fit precisely, account for this shrinkage.

Pack the bottom half of your flask (called the drag) with sand around half of your pattern. Dust the surface with parting powder (talcum powder works) to prevent sticking.

Place the top half (the cope) on top and pack it with sand around the rest of your pattern. Create channels called sprues and vents for pouring metal in and letting air escape.

Carefully separate the two halves and remove your pattern. You now have a hollow cavity in the exact shape of your object.

Fire up your furnace and place your crucible inside with your metal. Aluminum takes about 15-20 minutes to melt completely in a propane furnace.

The metal is ready when it flows like water and has a mirror-like surface. Use a steel rod to skim off any dross (impurities) floating on top.

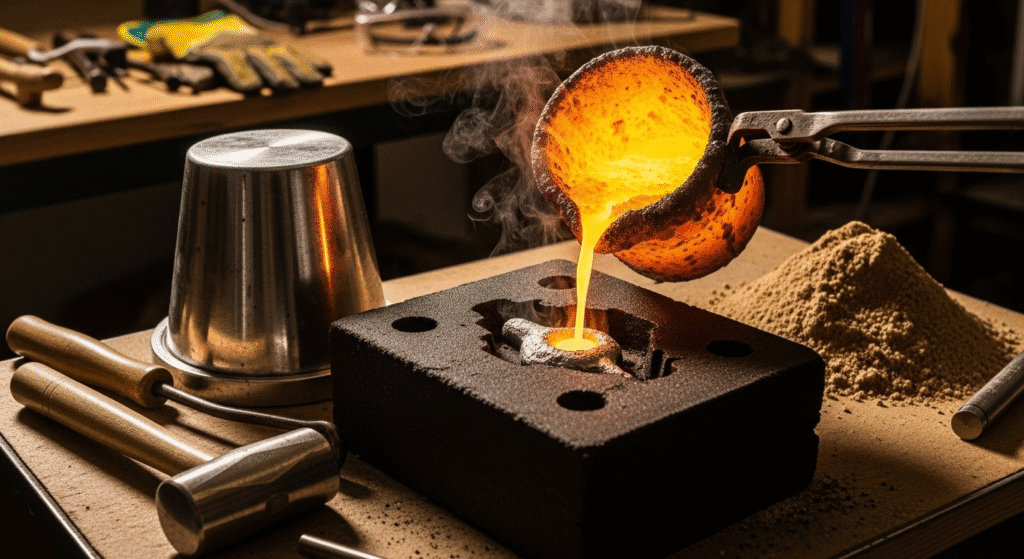

This is the moment of truth. Pour steadily and continuously into the sprue hole until metal appears at the vent holes.

Don’t stop pouring midway—this creates weak spots called cold shuts. The entire pour should take just a few seconds for small items.

Wait at least 10-15 minutes for small aluminum castings to solidify. Larger pieces need more time—rushing this step can result in a warped or cracked casting.

Break apart the sand mold to reveal your casting. The sand can be reused multiple times—just add a bit of water to replace what evaporated.

Your raw casting will have rough surfaces and extra metal where the sprues were. Use a hacksaw to remove the sprues and a file to smooth rough edges.

For a polished finish, work through progressively finer sandpaper grits from 80 up to 400 or higher. A bench grinder speeds up this process significantly.

Aluminum, brass, bronze, and pewter are ideal for home casting. They melt at manageable temperatures under 2,000°F that simple propane furnaces can achieve safely.

Sand casting involves molten metal at extreme temperatures, so yes, it carries risks. However, with proper safety equipment, ventilation, and careful technique, thousands of hobbyists do it safely.

From pattern to finished piece, expect 2-3 hours for your first casting. With practice, you can complete simple pieces in under an hour, not counting cooling time.

Yes, casting sand can be reused dozens of times. Simply break it up, add a small amount of water to replace what evaporated, and mix thoroughly before the next use.

Aluminum is perfect for beginners because it melts at relatively low temperatures, is readily available from recycled sources, and produces good detail in castings.