Choosing between cast and extruded aluminum can make or break your project. Pick the wrong one, and you’re looking at wasted tooling costs, parts that don’t perform, or production delays that throw your timeline off by weeks.

The confusion makes sense. Both processes use aluminum. Both produce strong, lightweight parts. Both have legitimate places in manufacturing. But they work in fundamentally different ways.

Here’s what you need to know: casting pours molten metal into molds, while extrusion pushes solid metal through shaped dies. That single distinction drives everything else—strength, cost, tolerances, and which applications each process handles best.

Aluminum casting melts the metal completely and pours it into a mold, where it solidifies into the final shape. Think of it like making ice cubes—liquid goes in, solid comes out.

Three main methods dominate the industry:

Die Casting uses high pressure—anywhere from 100 to 15,000 tons—to inject molten aluminum into hardened steel dies. The pressure forces metal into every corner of the mold, creating parts with fine details and thin walls. Most high-volume aluminum components you see, from engine blocks to smartphone frames, come from die casting.

Permanent Mold Casting relies on gravity instead of pressure. Workers pour molten aluminum into reusable metal molds and let gravity do the work. The parts aren’t as detailed as die castings, but the process costs less for medium-volume runs.

Sand Casting creates disposable molds from packed sand. It’s the oldest method and still the go-to choice for large parts or low-volume production where tooling costs need to stay minimal.

Here’s what all casting methods share: the aluminum starts as liquid (heated above 660°C), fills a cavity that defines the part’s shape, and solidifies inside that cavity. You get complex 3D geometries in one shot, with minimal machining needed afterward.

Extrusion forces heated—but still solid—aluminum through a shaped opening, like squeezing toothpaste through a tube. The metal emerges as a continuous profile with whatever cross-section the die creates.

The process follows a precise sequence:

Step 1: Billet Preparation. A cylindrical aluminum billet gets preheated to 400-500°C. That’s hot enough to make the metal soft and malleable, but not molten. The billet stays solid throughout the entire process.

Step 2: Die Setup. A steel die with the desired profile shape loads into the extrusion press. Die design determines what shapes you can create—everything from simple rectangles to complex hollow sections.

Step 3: Extrusion. A hydraulic ram pushes the billet against the die with tremendous force. The softened aluminum has nowhere to go except through the die opening, emerging as a continuous profile on the other side. Simple shapes can exit the press at 200 feet per minute; complex profiles might crawl out at just one foot per minute.

Step 4: Quenching. The fresh extrusion passes through a water spray or air blast that rapidly cools it. This fast cooling locks in certain material properties and prevents warping.

Step 5: Stretching. A stretcher grips both ends of the profile and pulls it taut. This straightens any curves and adds some work-hardening that improves strength.

Step 6: Cutting. Saws cut the long extrusion into specific lengths, typically 8 to 21 feet for standard orders.

Step 7: Aging. Heat treatment in an aging oven brings the aluminum to its final strength. The exact temperature and time depend on the alloy and desired properties.

The key difference from casting? The aluminum never melts. It stays solid, just soft enough to flow through the die. This creates a grain structure that aligns along the length of the profile—and that alignment is where extrusion gets its strength advantage.

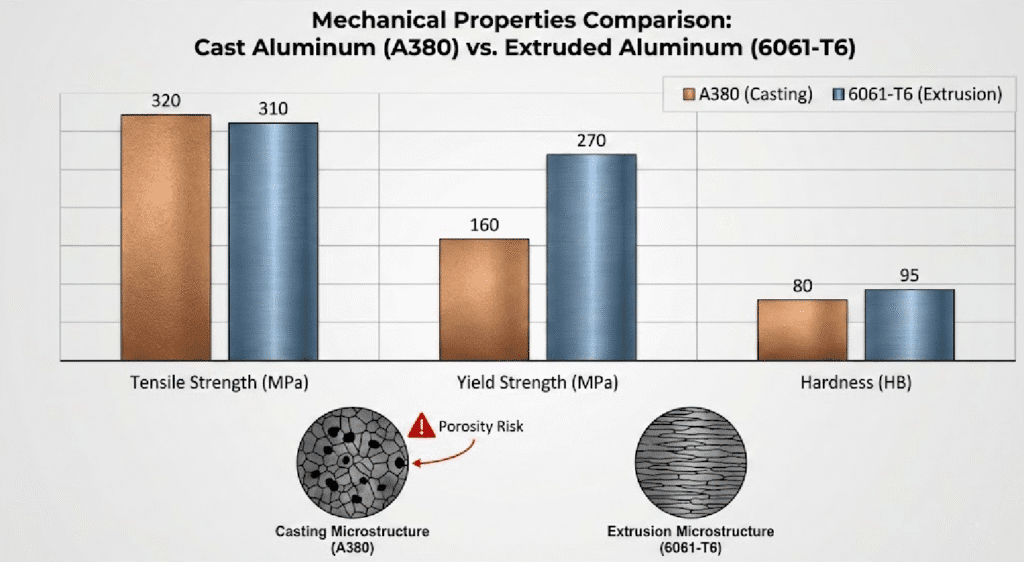

Extruded aluminum wins on strength. The numbers don’t lie—when you compare identical alloys processed both ways, the extruded version carries more load before it bends or breaks.

| Property | Cast Aluminum | Extruded Aluminum |

|---|---|---|

| Tensile Strength | Lower (porosity reduces it) | Higher (grain alignment helps) |

| Yield Strength | Variable depending on method | Consistently higher |

| Hardness | 70-85 HB typical | 73-95 HB typical |

| Stiffness | Higher (less elastic) | Lower (more flexible) |

| Porosity | Always a concern | Essentially zero |

| Fatigue Resistance | Lower | Significantly higher |

Why the difference? Two reasons.

First, extrusion aligns the metal’s grain structure along the profile direction. That’s like the difference between breaking a bundle of sticks lengthwise versus across—aligned grains resist pulling forces better.

Second, castings almost always contain some porosity. Tiny gas bubbles or shrinkage voids get trapped during solidification. These microscopic holes act as stress concentrators under load. Extrusions have none of that—the metal never melts, so there’s no opportunity for gas absorption or shrinkage cavities.

That said, cast parts do have higher stiffness. They’re less elastic, which matters for some applications. And casting can achieve comparable properties in specific situations with premium alloys and careful process control.

Different processes work with different alloy families. You can’t just swap them interchangeably.

Casting Alloys

| Alloy | Tensile Strength | Yield Strength | Hardness | Best Applications |

|---|---|---|---|---|

| A380 | 320-380 MPa (47 ksi) | 160 MPa (23 ksi) | 80-85 HB | Complex shapes, high-volume production |

| A356-T6 | 220-300 MPa (37 ksi) | 180 MPa (26 ksi) | 70-100 HB | Aerospace, automotive wheels |

A380 is the workhorse of die casting—roughly 80% of aluminum die castings use it. The high silicon content (7.5-9.5%) gives excellent fluidity for filling complex molds, and the copper content (3-4%) adds strength. If you’re not sure which casting alloy to specify, start with A380.

A356 costs more and can’t be die cast, but it responds to heat treatment. The T6 temper brings out significantly better properties than as-cast A380. You’ll find it in demanding applications like aircraft parts and premium wheels.

Extrusion Alloys

| Alloy | Tensile Strength | Yield Strength | Hardness | Best Applications |

|---|---|---|---|---|

| 6061-T6 | 310 MPa (45 ksi) | 270 MPa (39 ksi) | 95 HB | Structural parts, high-strength needs |

| 6063-T6 | 190 MPa (28 ksi) | 160 MPa (23 ksi) | 73 HB | Architectural, aesthetic applications |

6061-T6 is the structural workhorse. When strength matters—frames, brackets, load-bearing components—this is your alloy. It machines well, welds decently (though you lose strength in the heat-affected zone), and takes anodizing.

6063-T6 trades some strength for a better surface finish and easier extrusion. Window frames, door frames, and decorative trim typically use 6063 because appearance matters more than maximum strength. It anodizes beautifully.

| Cost Factor | Casting | Extrusion |

|---|---|---|

| Die/Mold Cost | $5,000-$100,000+ | $400-$7,000 |

| Die Lead Time | 6-12 weeks typical | 2-4 weeks typical |

| Die Lifespan | 50,000-500,000 shots | Much longer |

| Design Changes | Expensive, slow | More adaptable |

The crossover point between casting and extrusion depends on your specific part, but here’s a rough guide:

Low volume (under 500 parts): Extrusion almost always wins. The tooling cost difference alone makes the decision easy. You’re not making enough parts to amortize expensive casting dies.

Medium volume (500-5,000 parts): It depends on complexity. Simple extrusion profiles stay cheaper through this range. Complex 3D shapes that would need extensive secondary machining on an extrusion might favor casting.

High volume (over 5,000 parts): Casting starts making sense. The high tooling cost spreads across more parts, and the per-piece production cost drops below extrusion for many geometries.

Raw material costs the same either way—roughly $1.17/lb base price plus regional premiums around $0.65/lb for the US Midwest.

Finished part pricing varies widely:

Those numbers can flip depending on secondary operations. An extrusion that needs extensive machining might cost more than a near-net-shape casting that comes off the die ready to use.

| Choose Casting When… | Choose Extrusion When… |

|---|---|

| You need complex 3D geometry | Your part has a consistent cross-section |

| Internal cavities are required | High strength-to-weight ratio matters |

| You’re making 5,000+ parts | You’re making fewer than 5,000 parts |

| Fine details or decorative surfaces matter | Smooth surface finish is important |

| Near-net-shape saves machining cost | Long, uniform profiles are needed |

| Thin walls in complex configurations | Structural and load-bearing duty |

A few specific scenarios make the choice clear:

Need a bracket with mounting holes and ribbed reinforcement? Probably casting. The 3D features suit the process.

Building a frame from channels and tubes? Definitely extrusion. The consistent cross-sections and structural requirements play to its strengths.

Making 50 prototypes? Extrusion or CNC machining—the tooling cost for casting can’t be justified.

Producing 50,000 identical housings? Casting makes sense. The per-part cost advantage overwhelms the tooling investment at that volume.