KT Metal Casting delivers precision counterweight solutions to equipment manufacturers who demand reliable performance and consistent quality. Our expertise in high-density casting and weight distribution ensures optimal machine balance and operational safety.

Equipment manufacturers choose our counterweights because we understand how critical proper balance is to machine performance and operator safety. Our precision casting processes and quality control systems deliver counterweights that consistently meet exact weight specifications and dimensional requirements.

Our specialized foundry operations focus on high-density casting techniques specifically developed for counterweight applications, ensuring consistent material properties and precise weight distribution across all configurations.

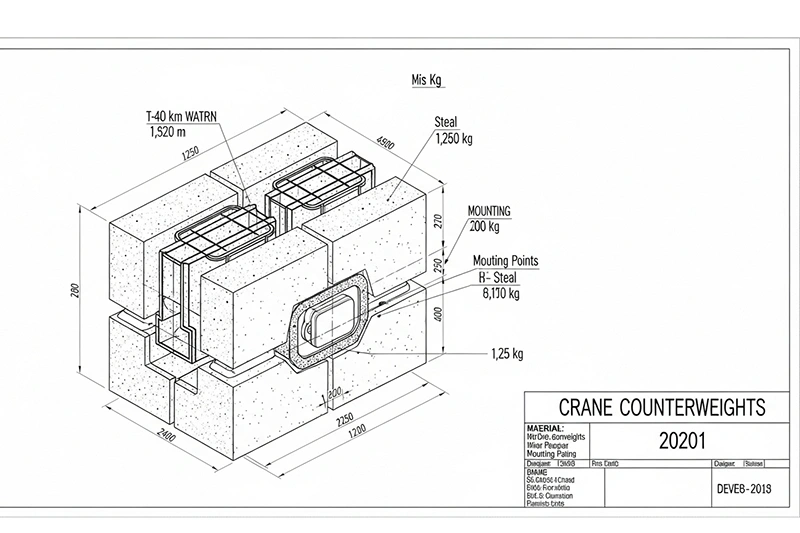

| Project Description | High-density counterweight castings for cranes, excavators, forklifts, elevators, and industrial machinery requiring precise balance and weight distribution. |

| Capabilities | Primary: High-density sand casting Secondary: Precision machining, weight verification, center of gravity marking |

| Dimensions | Weight range 50 lbs to 25,000 lbs, dimensions customized to application requirements |

| Tolerances | Weight accuracy: ±2% standard, ±1% for critical applications, dimensional: ±0.125″ |

| Materials | Gray cast iron Class 30/40, ductile iron 65-45-12, high-density steel alloys, lead-free alternatives available |

| Finish | Standard cast finish, optional primer coating, corrosion-resistant treatments, identification marking |

| Inspection | Certified weight verification, center of gravity measurement, dimensional inspection, material certification |

| Industry Use | Construction equipment, material handling, marine applications, industrial machinery, elevator systems |

| Volume | Single prototypes to production runs of 1,000+ pieces |

| Delivery | Specialized heavy freight logistics with crane truck delivery options |