KT Metal Casting specializes in high-performance sand cast flywheel components for customers who demand maximum power transfer efficiency and operational reliability. Our expertise addresses the most demanding rotational energy applications across performance and industrial sectors.

Performance-focused customers choose our flywheel castings when energy storage precision directly impacts system performance and power delivery. Our controlled processes ensure consistent rotational characteristics, perfect balance, and structural integrity essential for high-performance applications.

Our specialized foundry operations utilize precision casting controls specifically optimized for flywheel applications, ensuring consistent mass distribution and rotational properties across all configurations and weight specifications.

| Project Description | High-performance flywheel castings for automotive, marine, industrial generators, energy storage systems, and performance racing applications. |

| Capabilities | Primary: Precision sand casting with dynamic balancing Secondary: CNC finish machining, rotational testing, performance validation |

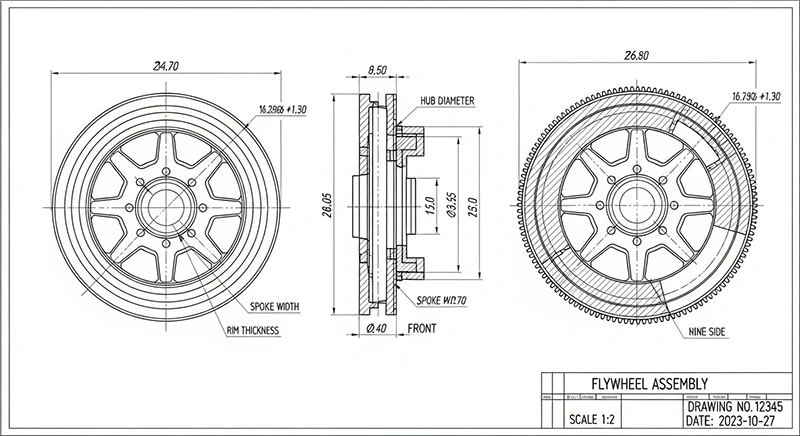

| Dimensions | Diameters 6″–60″, thickness 1″–12″, weight range 10 lbs–2,000 lbs |

| Tolerances | Rotational balance: ±0.5 oz-in Dimensional: ±0.003″ on critical surfaces |

| Materials | SAE 1045 carbon steel, 4140 alloy steel, ductile iron Grade 80-55-06, high-strength cast steel |

| Finish | Precision machined friction surfaces, optional heat treatment, induction hardening, shot peening for fatigue resistance |

| Industry Use | Automotive performance, marine propulsion, industrial power generation, energy storage, motorsports |

| Volume | Custom prototypes to 1,500 units per production run |

| Delivery | Express shipping for performance applications, global distribution network |