KT Metal Casting has earned the trust of engine and powertrain manufacturers who depend on us for flywheel housings that perform reliably in demanding applications. We know that your reputation rides on our quality.

Smart powertrain companies choose to work with us because we care about their success as much as they do. When you face challenging applications or tight project deadlines, you can count on our team to deliver solutions that protect your customer relationships.

Our foundry team treats every flywheel housing like it will power the most important application because we understand the critical role these components play in your equipment's performance.

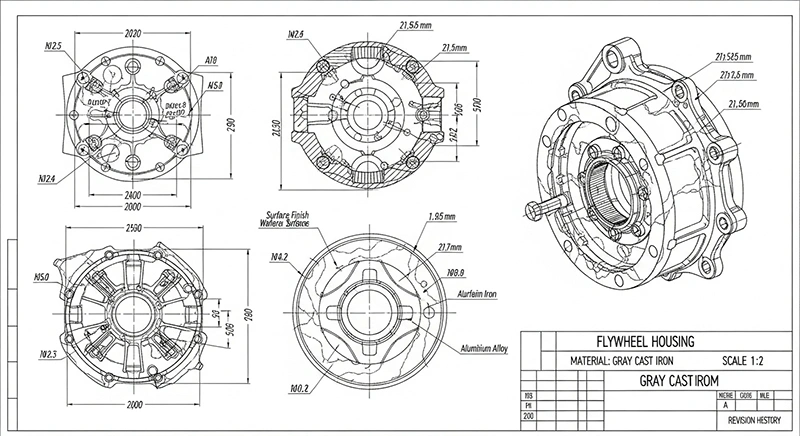

| Project Description | Dependable flywheel housing castings for diesel engines, industrial generators, marine propulsion, and heavy equipment applications that demand reliable power transmission. |

| Capabilities | Primary: Reliable sand casting with consistent quality Secondary: Precision machining, thorough testing, customer-focused service support |

| Dimensions | Housing diameters from 8″–60″, designed to accommodate specific flywheel and transmission requirements |

| Tolerances | ±0.005″ standard precision ±0.003″ available for critical bearing surfaces and mounting interfaces |

| Materials | Gray iron, ductile iron, aluminum alloys, and steel castings selected for durability and performance |

| Finish | Professional machined surfaces with optional protective coatings and treatments for extended service life in harsh environments |

| Industry Use | Diesel engines, generators, marine propulsion, construction equipment, and agricultural machinery |

| Volume | Flexible production from development prototypes to full runs up to 1,500 pieces |

| Delivery | Reliable on-time delivery throughout North America and international markets |