Every custom metal manifold we produce reflects our dedication to enhancing your diesel engine's efficiency through personalized design optimization.

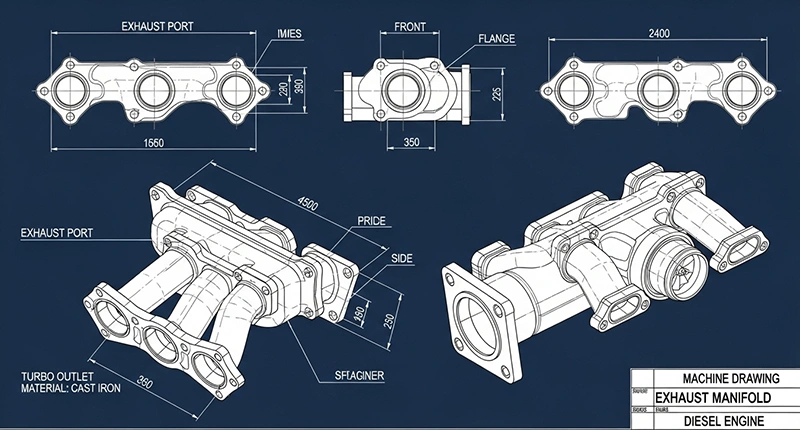

Our engineering team specializes in creating bespoke manifold solutions tailored to your specific flow requirements - from optimized runner lengths for improved volumetric efficiency to personalized port configurations that maximize turbulence and fuel atomization.

We customize wall thicknesses for thermal management, engineer precise plenum volumes for balanced cylinder distribution, and create specialized mounting bosses that integrate seamlessly with your engine architecture. Each custom metal manifold undergoes computational flow analysis to validate performance gains.

Whether you need compact intake manifolds for light-duty diesels or robust exhaust manifolds for heavy industrial applications, our bespoke approach ensures optimal results.

Our custom metal manifold capabilities encompass complete personalization - from material selection (high-silicon ductile iron for thermal cycling resistance, stainless steel for corrosion protection, or specialized alloys for extreme temperatures) to precision-machined sealing surfaces within ±0.003″.

We engineer bespoke internal geometries that minimize pressure drops, incorporate custom EGR passages, and design integrated sensor ports exactly where you need them. Every manifold receives thorough dimensional verification and pressure testing.

Beyond standard manufacturing, we deliver the exceptional quality your diesel engines demand through rigorous process control.

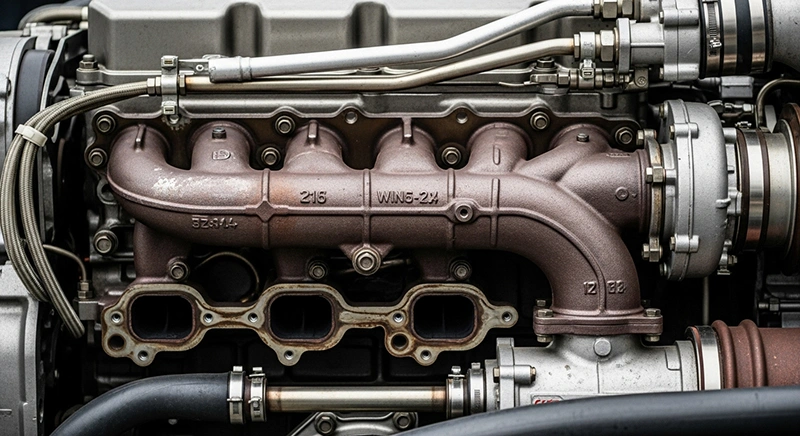

At KT Metal Castings, we recently completed a challenging custom metal manifold project for a major diesel generator manufacturer, demonstrating our end-to-end capabilities. From initial casting through precision CNC machining, we achieved the exacting tolerances required for optimal fluid dynamics.

Our bespoke approach included specialized heat treatment for dimensional stability, custom surface finishes to reduce flow turbulence, and personalized quality documentation including material certifications and dimensional reports. This commitment to excellence ensures your custom metal manifolds contribute to engine reliability and efficiency.

KT Metal Castings has earned the trust of diesel engine OEMs and power generation companies who demand flawless manifold performance. Our custom metal manifolds meet the strictest industry standards while delivering the personalized features that set your engines apart.

Leading manufacturers choose our bespoke approach because we understand that manifold quality directly impacts engine performance, emissions compliance, and durability. When you need custom metal manifolds that optimize combustion efficiency and withstand millions of thermal cycles, our personalized solutions deliver proven results.

Our foundry team approaches every custom metal manifold as a critical component of your engine's breathing system, implementing comprehensive quality controls that ensure consistent performance across production runs.

| Project Description | Premium custom metal manifold castings for diesel engines, power generation systems, and industrial applications demanding optimized flow characteristics and durability. |

| Capabilities | Primary: Precision sand casting with flow-optimized geometries Secondary: CNC machining, pressure testing, bespoke design engineering |

| Dimensions | Personalized configurations from compact 4-cylinder to large V12 diesel applications, engineered to your packaging constraints |

| Tolerances | ±0.005″ standard precision ±0.003″ for critical sealing surfaces and mounting interfaces |

| Materials | High-silicon ductile iron, gray iron, stainless steel (304/316), and specialized heat-resistant alloys selected for thermal cycling resistance |

| Finish | Precision-machined gasket surfaces, optional thermal barrier coatings, and personalized surface treatments for corrosion protection |

| Industry Use | Diesel engines, generator sets, marine propulsion, agricultural equipment, and industrial power systems |

| Volume | Bespoke production from prototype validation to full runs up to 2,500 pieces with consistent quality |

| Delivery | Reliable delivery schedules aligned with your engine production timelines |