KT Metal Casting stands as the industry's premier provider of custom sand cast motor housings, delivering unmatched expertise to electric motor manufacturers across the globe. Our deep understanding of motor housing requirements sets us apart in this specialized field.

Leading motor companies choose KT Metal Casting because we consistently transform their most challenging housing designs into reality through advanced sand casting techniques. The precision of our materials and casting processes directly enhances motor durability, thermal performance, and operational excellence.

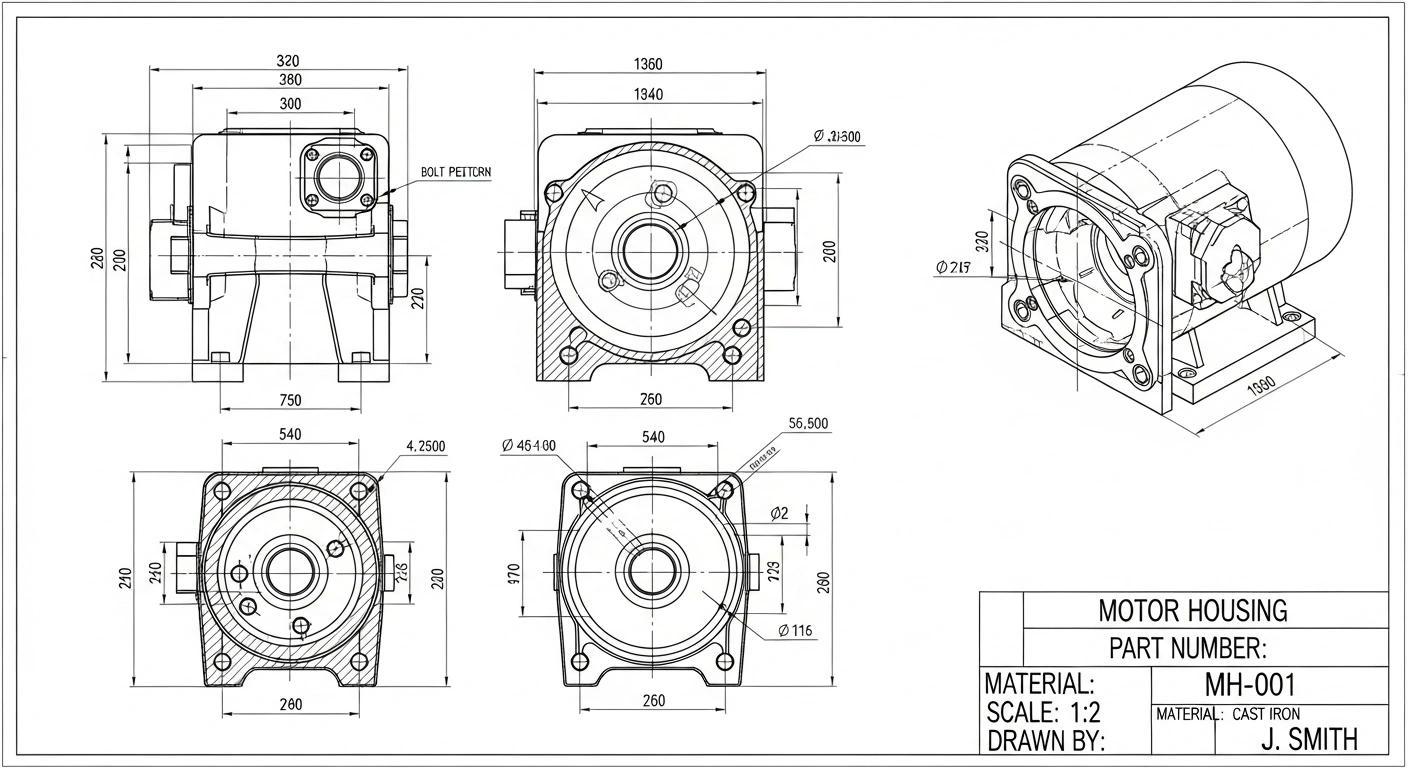

Our world-class foundry facility houses cutting-edge sand casting technology, ensuring every motor housing meets exacting specifications. We deliver custom solutions across a comprehensive range of sizes and configurations.

| Project Description | Motor housing unit for x-ray systems, forklifts, air conditioners, and other industrial motors and generators. |

| Capabilities | Primary: CNC lathe machining Secondary: Precision box/jig to hold shafting |

| Dimensions | Round diameters from 2″ to 24″ |

| Tolerances | ±0.0003″ (typical), up to ±0.0002″ on critical features |

| Materials | T60/T61 aluminum, 304/316 stainless steel, gray cast iron, ductile iron |

| Finish | RMS 16 surface finish; optional anodize, hardcoat, powder coat, passivation, electropolish |

| Inspection | Precision CMM (touch probe), optional vibration/noise testing, dynamic balancing |

| Industry Use | Medical, security, logistics, energy, and custom OEM solutions |

| Volume | Lot sizes from 10 to 10,000 |

| Delivery | North America and global export |

| Standards | TS 9000, ISO 9001:2015, RoHS/REACH compliance |

| Special Features | Integrated cooling fins, EMI shielding, IP65–IP67 sealing, part serialization with QR/barcode |