Our steel casting foundry utilizes multiple processes to match your project requirements.

Sand casting is our most versatile process for custom steel castings. It accommodates components from 10 lbs to 5,000 lbs and works well for both prototype and production volumes. Sand casting offers design flexibility and cost-effectiveness across a wide range of geometries.

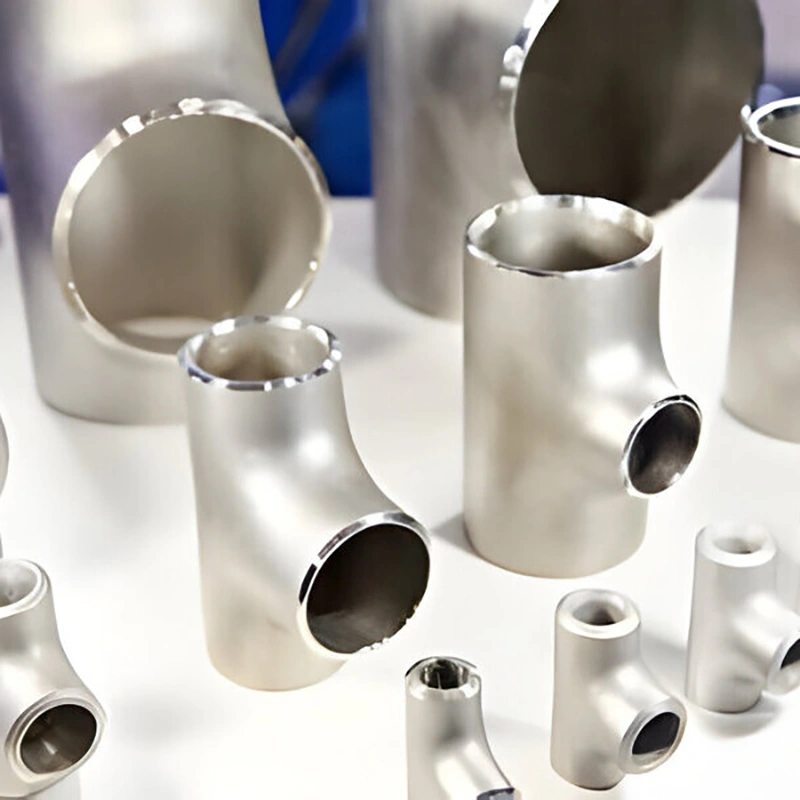

Investment casting (lost wax) delivers precision steel castings with complex geometries and tight tolerances. This process produces superior surface finish and dimensional accuracy, often reducing or eliminating secondary machining.

Our steel casting capabilities include components from 0.5 lbs to 5,000 lbs per piece.

We hold tolerances from ±0.005" to ±0.015" depending on casting process, size, and geometry.

Surface finish ranges from 125 Ra to 250 Ra as-cast. Finer finishes are achievable through secondary processing.

Our steel foundry pours 100+ ferrous alloys including carbon steel, alloy steel, stainless steel, tool steel, and specialty grades.

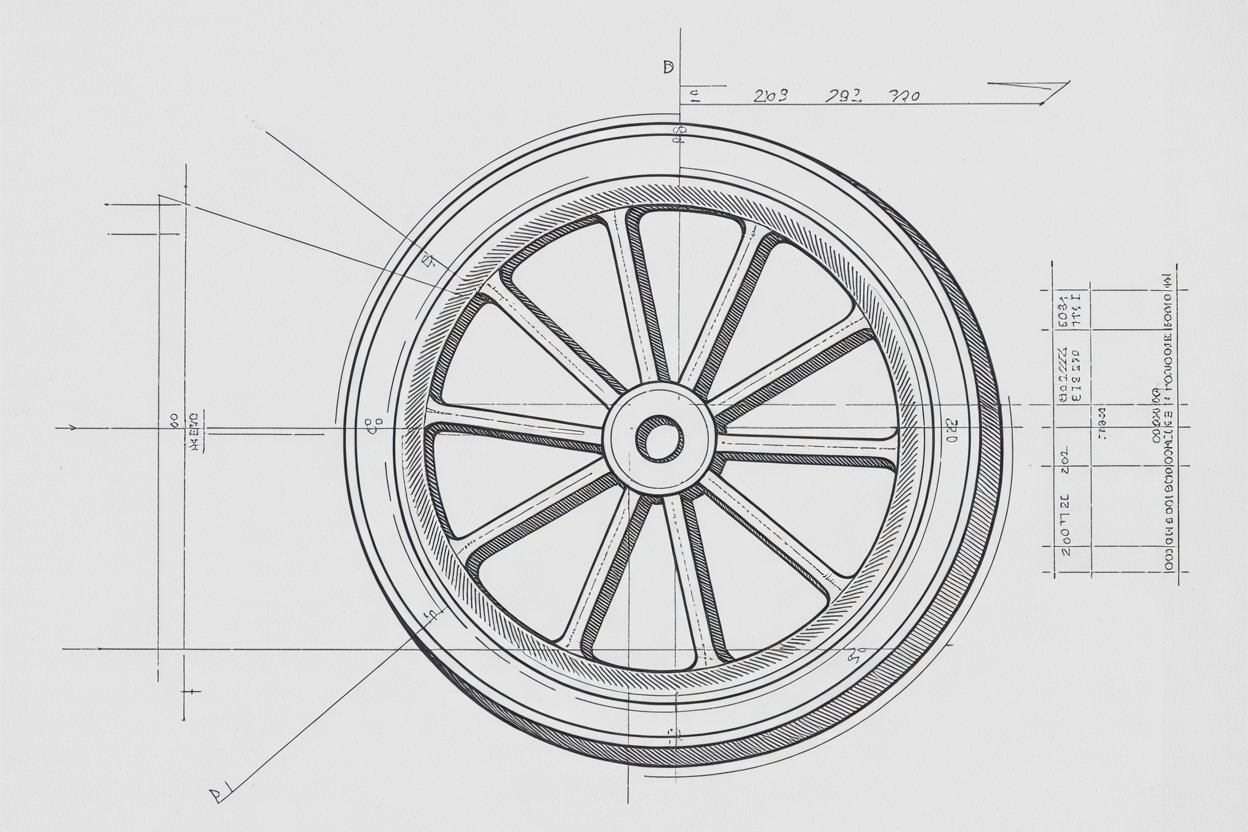

Our engineering team reviews your requirements, recommends optimal materials, and suggests design modifications for improved castability.

We work with all major CAD formats and provide DFM (Design for Manufacturability) consultation at no additional cost.

We create precision patterns matched to your specifications. Our steel casting foundry can work with customer-supplied patterns or develop new tooling in-house.

Induction melting furnaces ensure precise alloy composition and optimal metallurgical properties. Our melt technicians verify chemical composition before every pour. Temperature-controlled processes deliver consistent results across production runs.

We deliver finished components ready for assembly. Secondary services include CNC machining, drilling, threading, grinding, surface treatment, and protective coating.

Every steel casting undergoes inspection before shipment. We provide material certifications, dimensional reports, and test results as required.

KT Metal Casting exceeded our expectations on a complex manganese steel project.

The quality was outstanding and their technical support helped us optimize the design for better performance. We've been working with them for three years now.

The free testing service gave us complete confidence in the material composition and accuracy.

Every casting met our tight tolerances, and their turnaround time was impressive. Highly professional team from quote to delivery

As a long-time customer, I can say KT is more than just a supplier—they're a true manufacturing partner. Their foundry capabilities are impressive, and the quality control is among the best I've seen in the industry. They consistently deliver on promises

Our steel casting foundry works with carbon steel, alloy steel, stainless steel, tool steel, manganese steel, and specialty alloys. We pour 100+ grades and can cast to custom specifications.

Lead time depends on complexity, quantity, and finishing requirements. Simple castings with existing patterns typically ship in 4-6 weeks. New tooling development adds 2-4 weeks. Contact us with your specifications for accurate timing.

Our steel casting capabilities range from 0.5 lbs to 5,000 lbs per component. We handle everything from small precision parts to large structural castings.

Yes. Our engineering team reviews designs, suggests improvements for manufacturability, recommends optimal steel grades, and helps optimize costs. We work with various CAD formats and sign NDAs to protect proprietary designs.

We have no strict minimum order quantity. Our steel foundry accommodates single prototypes through high-volume production. Contact us to discuss your specific requirements.

Absolutely. We offer complete secondary services including CNC machining, drilling, threading, heat treatment, surface treatment, and coating. We deliver fully finished, ready-to-install components.

Every production batch undergoes chemical analysis, dimensional inspection, and mechanical testing. We offer NDT services including UT, MT, PT, and RT. Full material traceability and certifications are provided with shipment.

Send us your drawings (2D or 3D CAD), material specifications, quantity requirements, and any special testing or certification needs. Our team provides detailed quotations within 24-48 hours.