KT Metal Casting operates as a specialized supplier of precision sand cast valve components, providing advanced metallurgical expertise to valve manufacturers requiring superior performance characteristics. Our technical capabilities address the most demanding valve casting applications.

Industrial customers trust our valve castings for critical applications where casting precision directly impacts system performance and safety. Our controlled processes and material expertise ensure consistent mechanical properties, dimensional accuracy, and surface integrity essential for reliable valve operation in demanding environments.

Our specialized foundry operations utilize advanced process controls and metallurgical systems specifically configured for valve casting applications, ensuring consistent results across all geometric configurations and material specifications.

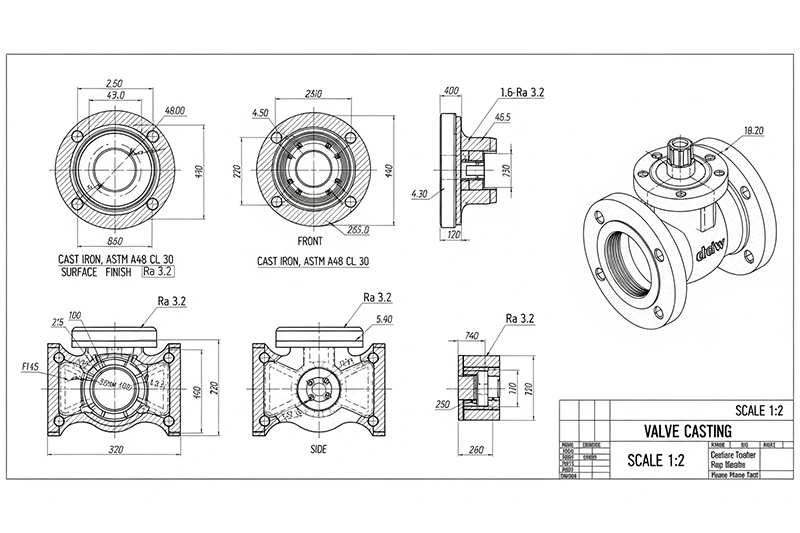

| Project Description | Precision valve body, bonnet, actuator housing, and trim component castings for critical service ball valves, gate valves, control valves, and specialized fluid control applications. |

| Capabilities | Primary: Controlled atmosphere sand casting Secondary: CNC machining centers, coordinate measuring systems, non-destructive testing |

| Dimensions | Port diameters 0.5″ to 48″, wall thickness 0.125″ to 4″, pressure class ratings to ASME 2500 |

| Tolerances | Standard: ±0.005″, precision applications: ±0.0015″ on critical sealing interfaces |

| Materials | ASTM A351 CF8M/CF3M stainless steel, ASTM A494 CW-12MW, ASTM A395 ductile iron, specialty corrosion-resistant super alloys |

| Finish | Precision machined surfaces Ra 32-125 μin, optional specialized coatings: hard chrome, tungsten carbide, ceramic thermal spray |

| Industry Use | Upstream/downstream petroleum, petrochemical processing, power generation, nuclear applications, aerospace fluid systems |

| Volume | Prototype development through 2,500 units per production run |

| Delivery | Global supply chain integration with expedited logistics capabilities |

| Special Features | Zero-leakage designs, extreme temperature performance (-320°F to +1500°F), radiation-resistant materials, custom metallurgy development |