Creating a cavity for sand casting requires building a sand mold around a pattern that matches your desired metal part. You’ll pack special casting sand around a pattern, remove the pattern to leave a hollow space, then pour molten metal into that cavity to create your final piece.

The entire process takes about 2-4 hours for small parts and can produce everything from engine blocks to decorative sculptures. Most hobbyists can master the basics in a weekend with around $200 worth of equipment and materials.

Your pattern is an exact replica of the part you want to cast, plus a small amount extra for shrinkage. Wood patterns work best for beginners because they’re easy to shape and sand smooth.

Add 1-2% extra size to your pattern to account for metal shrinkage when it cools. A 10-inch pattern should actually measure 10.1-10.2 inches.

Apply several coats of shellac or polyurethane to seal wooden patterns. This prevents the sand from sticking and makes pattern removal much easier.

Mix 100 parts silica sand with 6-8 parts bentonite clay and just enough water to make it hold together when squeezed. The mixture should clump in your hand but break cleanly when you snap it.

Too much water makes the sand stick to your pattern. Too little water causes the mold to crumble when you remove the pattern.

You can buy pre-mixed casting sand (called greensand) for about $30 per 50-pound bag. This saves time and guarantees the right consistency.

Place the drag (bottom half of your casting box) upside down on a flat board. The drag holds the bottom half of your mold.

Dust the board lightly with parting powder or talcum powder. This prevents the sand from sticking to the board.

Center your pattern on the board with the flattest side down. Leave at least 1 inch of space between the pattern and the flask walls on all sides.

Sift a thin layer of fine sand directly over the pattern to capture small details. This facing sand should be about 1/4 inch thick.

Pack the rest of the drag with regular casting sand using a ramming tool. Start gently around the pattern, then increase pressure as you build up layers.

Level the sand flush with the top of the drag using a straight edge. The surface needs to be perfectly flat for the two mold halves to fit together properly.

Carefully flip the entire drag assembly so the pattern faces up. The board that was on bottom is now on top.

Remove the board to expose the pattern embedded in the sand. Dust the exposed sand surface with parting powder to prevent the two mold halves from sticking together.

Place the cope (top half of the flask) on top of the drag. The alignment pins should fit perfectly to ensure proper registration.

Push a tapered wooden dowel (sprue pin) into the sand next to your pattern. This creates the channel where you’ll pour molten metal.

Position the sprue about 1/2 inch from the pattern edge. Angle it slightly for smoother metal flow.

Add a second, smaller riser pin on the opposite side if your pattern is larger than 3 inches. The riser lets air escape and shows when the mold is full.

Repeat the sifting and ramming process for the cope. Pack sand carefully around the sprue and riser pins without disturbing them.

Build the sand up about 1 inch above the cope’s top edge. This extra sand creates a pouring basin that makes filling easier.

Carve a shallow funnel shape around the sprue opening. This pouring basin should be about 2 inches wide.

Gently tap and twist the sprue and riser pins before pulling them straight up. These holes connect your pouring basin to the pattern cavity.

Separate the cope from the drag by lifting straight up. Any sideways movement can damage the sand edges.

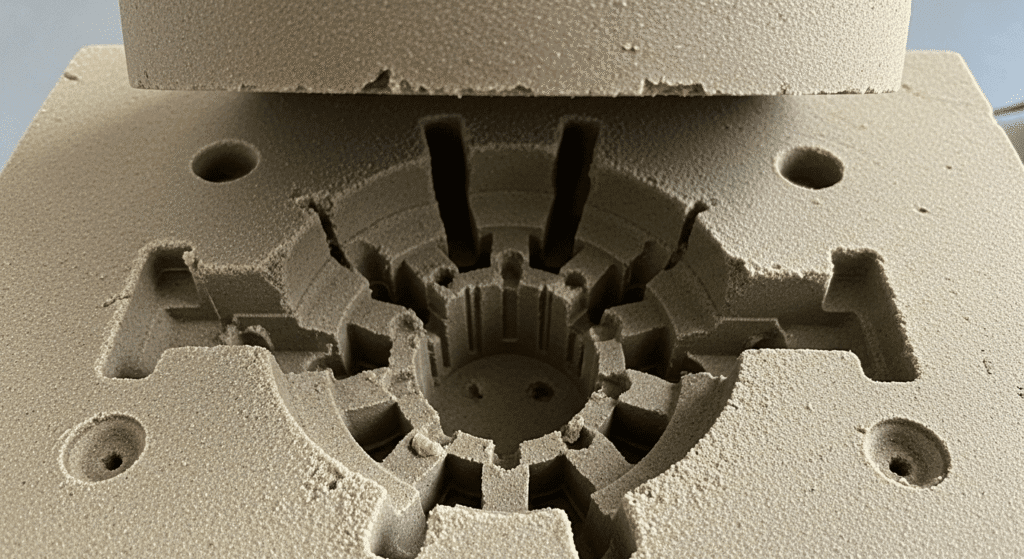

Carefully remove the pattern from the drag by tapping it lightly and lifting straight up. The cavity left behind is your mold.

Use a small spoon or gate cutter to carve channels from the sprue hole to the pattern cavity. These gates should be about 1/4 inch deep and wide.

Slope the gates downward toward the cavity. This helps metal flow smoothly and reduces turbulence.

Clean any loose sand from the cavity using compressed air or a small brush. Even tiny sand particles can create defects in your casting.

Carefully place the cope back onto the drag, using the alignment pins as guides. The two halves should fit together perfectly with no gaps.

Place weights on top of the cope or clamp the flask together. The pressure from molten metal can separate the mold halves if they’re not secured.

Your cavity is now complete and ready for pouring. Make sure your metal is fully molten before you begin the pour.

Silica sand with 6-8% bentonite clay creates the strongest molds. The clay acts as a binder when moistened, while the silica withstands high temperatures without breaking down.

Squeeze a handful of sand tightly—it should hold its shape when you open your hand but break cleanly when snapped. If it crumbles, add water; if it sticks to your hand, add dry sand.

Yes, casting sand can be reused many times. Break up the old mold, remove any metal bits, add a small amount of water and clay to refresh the mixture, then mix thoroughly.

Common defects come from sand that’s too wet (causing gas bubbles), patterns without enough draft angle (causing torn molds), or pouring metal too fast (creating turbulence and sand erosion).

Add 1-3 degrees of draft angle to all vertical surfaces. This slight taper allows the pattern to pull out cleanly without damaging the sand cavity walls.

Green sand contains moisture and clay as a binder, while dry sand molds are baked or chemically bonded. Green sand works well for most hobby casting and doesn’t require special equipment.