Nothing slows down a quote more than an endless cycle of back-and-forth emails trying to clarify what’s actually needed. Industry data shows 3-4 days are typically wasted during the quoting period due to missing information, and some suppliers take up to three weeks to return quotes when RFQs arrive incomplete.

An iron casting quote is only as good as the information you provide. The hour spent preparing complete specifications upfront saves days of clarification requests later. Here’s what foundries actually need to quote your project accurately.

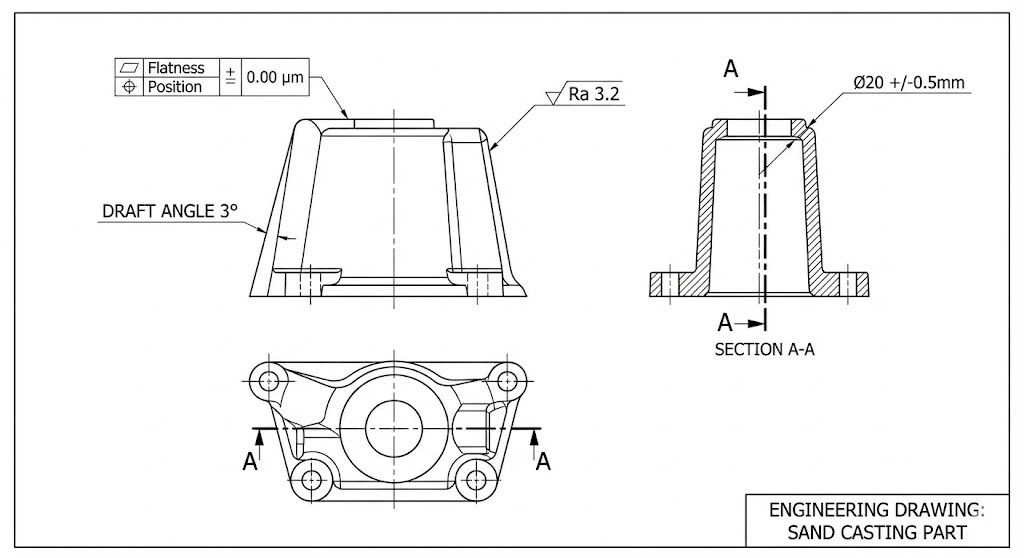

Foundries need both 2D drawings and 3D models to quote accurately. The 2D drawing provides dimensions and tolerances in a standardized format. The 3D CAD model (STEP or IGES format preferred) enables accurate weight calculations and reveals geometry issues that flat drawings can hide.

Your drawings should include:

Sending SolidWorks native files with exported PDFs is ideal. When foundries must create their own drawings from incomplete information, they either add time to the quote process or make assumptions that lead to requotes later.

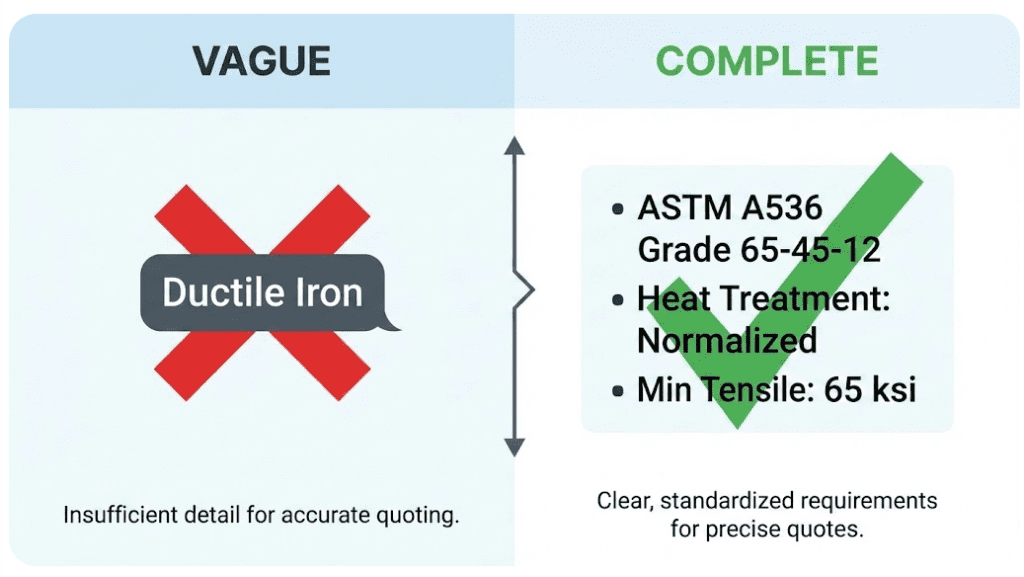

Specify your material with the full grade designation and standard reference. “Ductile iron” tells the foundry almost nothing. “ASTM A536 Grade 65-45-12” tells them exactly what mechanical properties you need and what chemistry to achieve.

For common metals used for sand casting, include:

If you’re uncertain which grade fits your application, describe the operating environment and functional requirements. A good foundry can recommend appropriate grades. But when you know the grade, specify it. Vague material specs lead to quotes based on assumptions, and those assumptions often differ from what you actually needed.

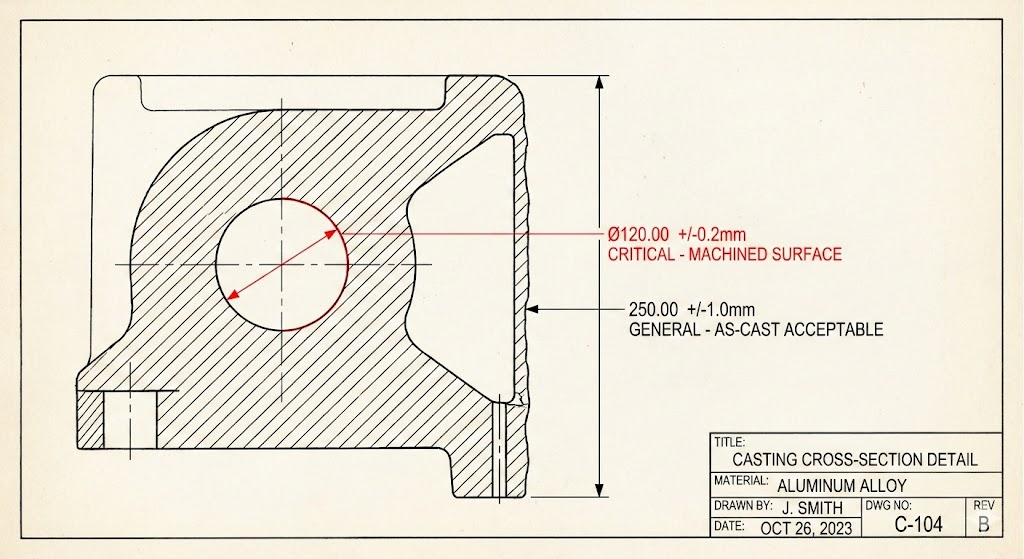

Sand casting achieves general tolerances of +/-0.4mm to +/-1mm depending on the dimension and process. For tighter requirements, machining is required.

The distinction that matters most: which dimensions are critical and which are general?

Mark critical dimensions clearly on your drawing and, when possible, explain why they’re critical. A foundry that understands why a bore needs +/-0.2mm can optimize the casting to hold that tolerance. A foundry that just sees numbers everywhere will quote based on the tightest tolerance across the board.

Over-tolerancing non-critical dimensions drives up costs unnecessarily. Every tight tolerance you specify may require machining, inspection, or process controls that add cost. Specify what you actually need, not what would be nice to have.

Quote accuracy depends heavily on business context:

Quantity information:

Timeline information:

Annual volume forecast determines tooling recommendations. A pattern for 100 parts per year costs far less than one designed for 2,000 parts annually. Inflating your volume to seem like a bigger customer backfires when the tooling investment doesn’t match actual orders.

For straightforward parts with complete information, many foundries can return quotes within 24-48 hours. Complex geometries or incomplete specs push that to weeks.

According to Jesse Milks, President of State Line Foundries, “About 80 percent of the time, when we first get a request for quotation, we don’t know the qualification needs.”

This is where most RFQs fall short. Engineering provides technical specs, but quality department requirements often arrive after the quote is already submitted. Then everyone goes back to the drawing board.

Specify upfront:

Quality requirements affect both price and lead time. A casting that requires 100% X-ray inspection costs more than one with visual inspection only. Build these requirements into your initial RFQ rather than discovering them after tooling is already made.

Pattern costs vary dramatically based on complexity and expected volume:

If you have an existing pattern from a previous supplier, mention it immediately. Include photos if possible. Reusing existing tooling (when feasible) eliminates significant cost and lead time.

Key tooling questions to address in your RFQ:

Wood patterns typically serve up to 100 parts per year before degrading. Metal patterns support 2,000+ annual volumes. Your volume forecast helps the foundry recommend appropriate tooling investment.

Before sending your next casting RFQ, verify you’ve addressed:

Technical specifications:

Business context:

Quality requirements:

Tooling status:

Complete information doesn’t just speed up quotes. It results in more accurate pricing, because foundries aren’t padding for unknowns. The time you invest in preparation comes back as faster responses and competitive prices.