The investment casting process relies on removing wax pattern completely from ceramic shells. Getting the wax out is critical—any residue ruins the final metal part.

Three main methods dominate the industry: steam autoclave, flash-fire, and dry oven dewaxing. Each method suits different production needs and types of wax.

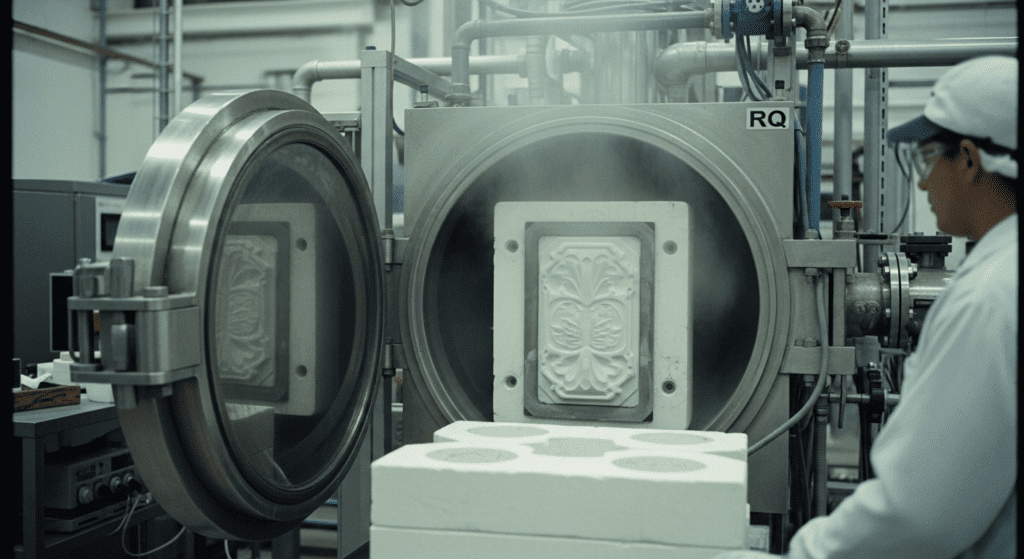

Steam autoclave dewaxing uses high-pressure steam to melt wax patterns quickly and cleanly. This method works best for complex parts and delicate ceramic shells.

The process combines heat and pressure to remove wax in minutes rather than hours. Most foundries prefer this method for high-value parts where shell integrity matters most.

Place ceramic shells with wax patterns inside the autoclave chamber. Position shells with gates facing downward to help wax drain out.

Space shells evenly to allow steam circulation around all surfaces.

Close the autoclave door and create an airtight seal. Start the pressurization cycle to reach 50-90 PSI.

Inject steam at 250-350°F into the chamber. The combination of heat and pressure melts wax in 5-15 minutes.

Open drain valves to remove melted wax from the chamber bottom. Most wax flows out within the first few minutes.

Collect wax for recycling and reuse in new patterns.

Slowly release pressure to prevent shell damage. Open the chamber and remove dewaxed shells.

Shells are now ready for final firing before metal pouring.

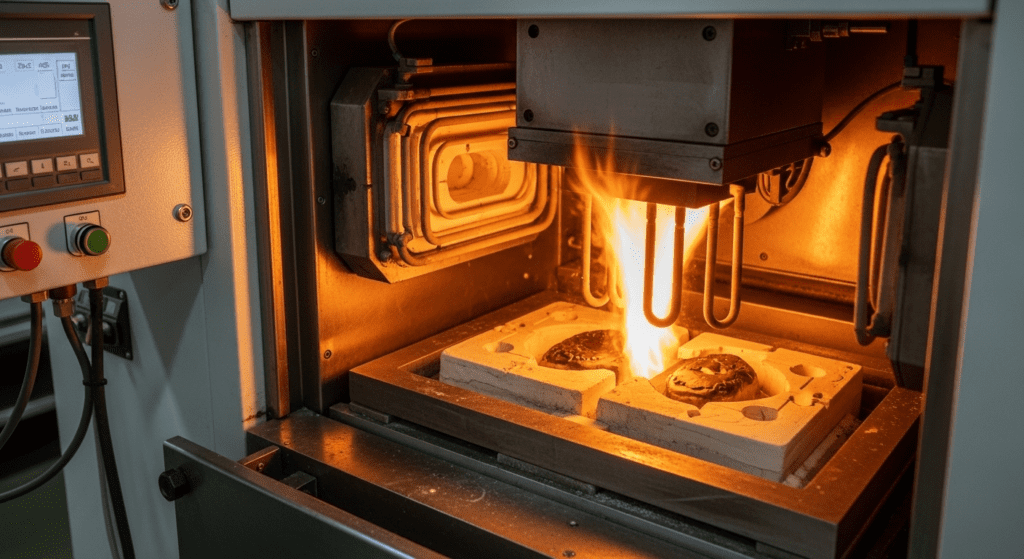

Flash-fire dewaxing burns out wax patterns using direct flame exposure at extreme temperatures. This aggressive method works fastest but requires robust ceramic shells.

The process heats shells to 1,800-2,000°F in seconds. Such rapid heating vaporizes wax before it can soak into the ceramic.

Heat the flash-fire furnace to operating temperature of 1,800-2,000°F. Ensure even temperature distribution throughout the chamber.

Proper preheating prevents cold spots that leave wax residue.

Place ceramic shells directly into the hot furnace using automated loading equipment. Orient shells to promote wax drainage and combustion.

Expose shells to direct flame for 5-10 seconds. The extreme heat instantly vaporizes and burns the wax pattern.

Any wax becomes fuel for the combustion process.

Maintain shells at temperature for 30-60 minutes total. This extended heating burns out any remaining wax traces.

Remove shells from the furnace and allow controlled cooling. Inspect for cracks or wax residue before proceeding.

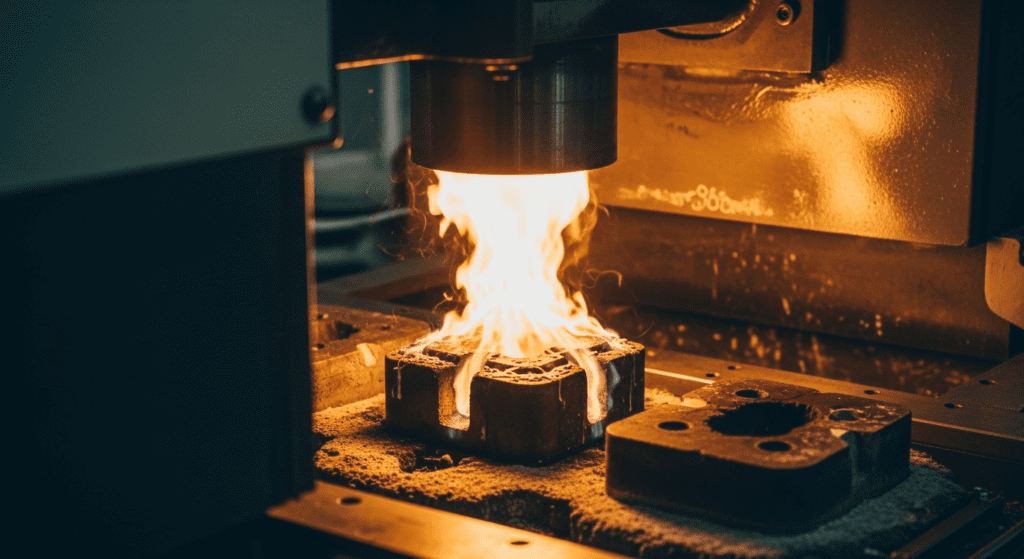

Dry oven dewaxing slowly heats ceramic shells in a controlled environment. This gentle method suits delicate patterns and specialized wax formulations.

The process takes 12-24 hours but produces consistent results. Many foundries use this method for prototype and low-volume production.

Load ceramic shells into the burnout furnace with adequate spacing. Position shells to allow air circulation and wax drainage.

Set the furnace to increase temperature gradually from room temperature to 200°F. This initial phase softens wax without thermal shock.

Slow heating prevents shell cracking in complex geometries.

Maintain temperature at 250-300°F for several hours. This allows wax to melt and drain completely from all shell cavities.

Ramp temperature to 1,000-1,500°F over 4-6 hours. This phase burns out any remaining wax residue and strengthens the ceramic shell.

Hold at maximum temperature for 2-4 hours for complete burnout. Then begin controlled cooling to prevent thermal stress.

Proper cooling maintains shell strength for metal pouring.