Determining whether aluminum is cast or extruded is straightforward once you know what to look for. Cast aluminum is melted and poured into molds to create complex shapes, while extruded aluminum is pushed through a die to create long, uniform profiles. You can identify the difference through visual inspection and simple tests that don’t require special equipment.

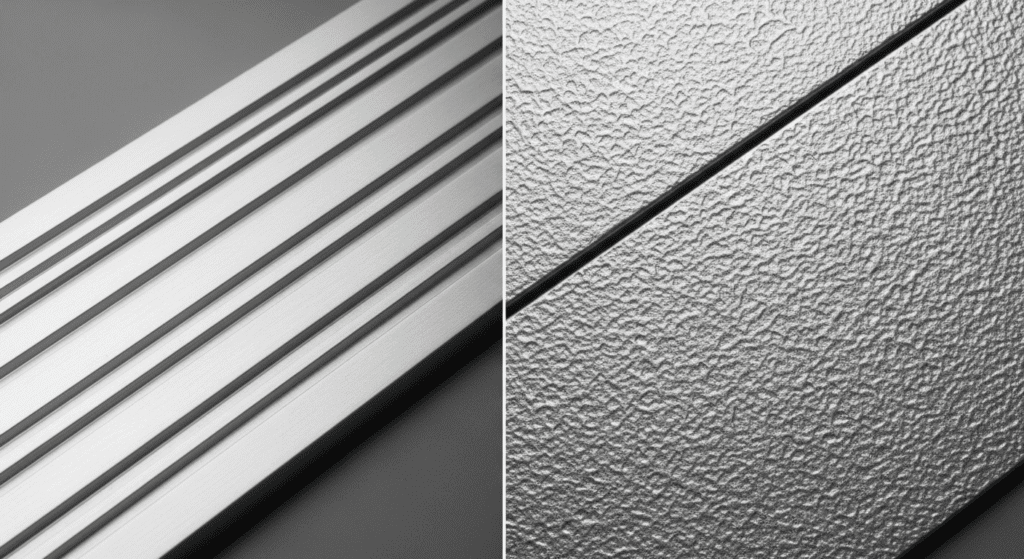

Cast aluminum has a rough, granular surface texture that looks like fine sandpaper. You’ll often see a slightly porous appearance with tiny dimples or pits across the surface. The finish typically appears matte or dull, even when cleaned.

Extruded aluminum, on the other hand, has smooth, consistent surfaces with visible linear streaks running along its length. These streaks come from the extrusion process itself. The surface usually has a more uniform, semi-glossy appearance.

If you run your finger along the surface, cast aluminum feels gritty or textured. Extruded aluminum feels smooth and uniform in the direction of extrusion.

Cast aluminum excels at complex, three-dimensional shapes with varying wall thicknesses. You’ll find it in engine blocks, decorative furniture, and intricate machine parts. The shapes often include curves, hollow sections, and detailed features that would be impossible to extrude.

Extruded aluminum always has a consistent cross-section along its entire length. If you can imagine pushing Play-Doh through a shaped opening, that’s what extruded aluminum looks like.

The wall thickness tells another story. Cast aluminum often has thick and thin areas in the same piece. Extruded aluminum maintains uniform wall thickness throughout.

Cast aluminum pieces show clear evidence of the molding process. Look for raised lines where the mold halves came together – these parting lines are dead giveaways. You might also spot small nubs or rough spots where the molten aluminum entered the mold (called gates or sprues).

These marks often appear on less visible surfaces or edges of the part. Manufacturers sometimes grind them down, but you can usually still feel or see a slight ridge.

Extruded aluminum won’t have any parting lines or gate marks. Instead, you might notice die lines – extremely fine parallel lines running the length of the piece.

Cast aluminum frequently contains small air bubbles trapped during the pouring process. These create tiny holes or porous areas, especially visible on machined or cut surfaces. You might need a magnifying glass to see them clearly.

Surface defects in cast aluminum include sand inclusions (if sand-cast), cold shuts (where two flows of metal didn’t properly fuse), or shrinkage marks. These imperfections are normal and don’t necessarily indicate poor quality.

Extruded aluminum rarely has porosity issues. Its defects are different – you might see surface scratches, die lines, or slight warping along the length.

Cast aluminum is brittle and will crack or break rather than bend. If you apply pressure to a thin section, it’ll snap suddenly without much deformation. This brittleness comes from its grain structure and potential internal porosity.

Extruded aluminum bends more readily and shows plastic deformation before breaking. It’ll gradually curve under pressure, especially perpendicular to the extrusion direction.

Never perform this test on parts you don’t own or can’t afford to damage. Even small bends can ruin functional components.

Cast aluminum is generally softer and easier to scratch with a steel tool or knife. The scratch will appear rough and might chip small pieces away from the edges. The material tends to crumble slightly rather than cutting cleanly.

Extruded aluminum, particularly common alloys like 6061 or 6063, resists scratching better. When you do scratch it, the mark appears cleaner and more uniform. The metal tends to displace rather than chip away.

Try this test in an inconspicuous area. A simple steel nail or knife point works well for comparison.

Tap cast aluminum with a metal object and you’ll hear a dull, short thud. The sound doesn’t resonate much because the irregular grain structure and possible internal voids dampen vibrations.

Extruded aluminum produces a clearer, higher-pitched ring that sustains longer. The uniform structure allows sound waves to travel more efficiently.

This test works best on similar-sized pieces. Thickness and mounting affect the sound significantly.

When grinding cast aluminum against a wheel, you’ll see very few sparks – maybe some white specks. The sparks that do appear are short and don’t branch out. Cast aluminum often contains silicon or other elements that slightly alter the spark pattern.

Extruded aluminum produces virtually no sparks when ground. You might see tiny white particles, but nothing like the shower of sparks from steel.

Always wear safety glasses when performing spark tests. The metal particles are extremely hot and can cause serious eye injuries.