Investment casting is a manufacturing process that creates precise metal parts by pouring molten metal into ceramic molds. It’s perfect when you need complex shapes with smooth surfaces and tight tolerances.

Finding the right supplier for this process can make or break your project. A good partner delivers quality parts on time, while a poor choice leads to delays, defects, and headaches.

This guide walks you through finding reliable suppliers and building successful partnerships step by step.

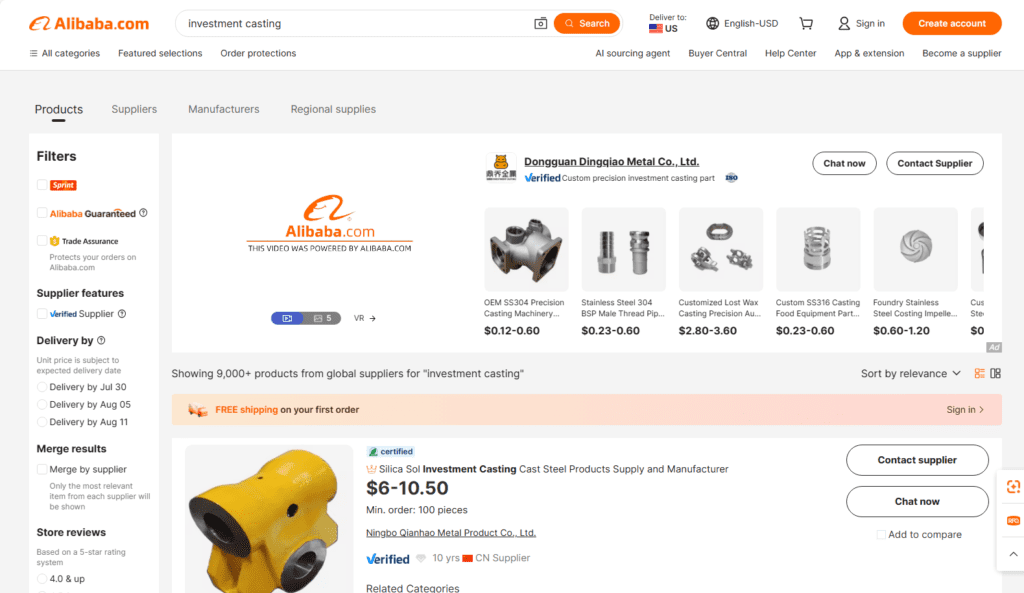

Start your search using online B2B platforms like Alibaba, ThomasNet, and Global Sources. These sites let you filter suppliers by location, certifications, and capabilities.

Don’t forget about trade shows and industry events. The Investment Casting Institute holds annual conferences where you can meet dozens of suppliers face-to-face.

Industry directories work great too. The AFS Casting Source Directory lists qualified foundries across North America.

Check if suppliers can handle your specific metal needs. Ask them directly: “What alloys do you pour, and how much can you produce monthly?”

For example, if you need titanium parts but that’s only 5% of their work, expect longer lead times. Find suppliers who regularly work with your required materials.

Look at their production capacity. Can they handle your part size and quantity?

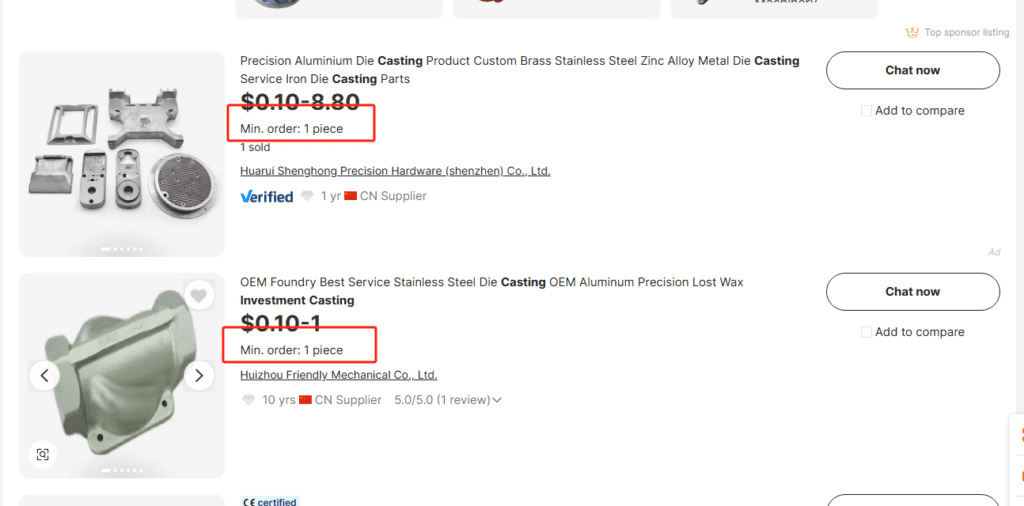

Small foundries might struggle with large orders, while big operations may not want small runs. Match your needs to their sweet spot.

Quality certifications tell you a lot about a supplier. Look for ISO 9001 as a minimum standard.

Aerospace work requires AS9100. Medical devices need ISO 13485. Make sure they have the right certifications for your industry.

Ask about their testing capabilities. Good foundries have in-house labs for checking metal composition and part quality.

They should offer services like X-ray inspection, ultrasonic testing, and dimensional checks. Suppliers who outsource all testing usually take longer to deliver.

Many casting suppliers offer extra services that save you time and money. These might include CNC machining, heat treating, or surface finishing.

Getting casting and machining from one supplier simplifies your supply chain. It also prevents finger-pointing if problems arise.

Some suppliers provide design help too. They can review your part drawings and suggest improvements that reduce costs or increase strength.

Always get sample parts before placing big orders. This shows you exactly what the supplier can deliver.

Test samples thoroughly. Check dimensions with precise measuring tools. Verify surface finish meets your standards.

Request material certificates that prove the metal composition. Good suppliers provide detailed inspection reports for every sample.

If a supplier hesitates to provide samples or documentation, consider it a red flag.

Write RFQs that leave no room for confusion. Include complete specifications like tolerances, surface finish requirements, and exact material grades.

State your quantities clearly. Need 100 pieces now and 1,000 monthly after that? Say so upfront.

Set realistic delivery expectations. First articles typically take 6-8 weeks, while production runs need 10-12 weeks.

Here’s what a good RFQ includes:

Don’t just pick the cheapest option. Look at the total cost including shipping, import duties, and any tooling fees.

A supplier charging $50 per part with free tooling might beat one charging $45 per part plus $5,000 in tooling costs.

Consider lead times too. Can you afford to wait 16 weeks for the cheapest supplier? Sometimes paying 10% more for 8-week delivery makes sense.

Check what’s included in each quote. Does it cover all required testing? Are certificates included? These details matter.

Visit suppliers in person when possible. Walking through their facility tells you more than any brochure can.

Look for clean, organized workspaces. Check if equipment appears well-maintained. Watch how workers handle parts.

If you can’t visit, request a video tour. Many suppliers now offer virtual walk-throughs that show their capabilities.

During audits, verify their certifications are current. Check that their quality procedures match what they promised.

Good contracts prevent problems later. Specify exactly what you’re buying, including all technical requirements.

Include clear payment terms. Common options include:

Set quality standards with specific defect rates. For example: “Maximum 1% defect rate using ANSI/ASQ standards.”

Add warranty terms that protect you. Most suppliers offer 12-month warranties against defects in materials or workmanship.

Don’t forget confidentiality agreements if your designs are proprietary.

Work with suppliers to establish inspection procedures. First Article Inspection (FAI) catches problems before full production starts.

Require documentation for every shipment. This includes:

Set up regular quality reviews. Track defect rates, return rates, and customer complaints.

Finding reliable investment casting suppliers takes effort upfront. But the time you invest in research, testing, and relationship building pays off through better quality, reliable delivery, and fewer headaches.