A $1,000 wood pattern that needs replacement every 500 cycles costs $2 per casting. A $3,000 aluminum pattern lasting 50,000 cycles costs $0.06 per casting. That 33x difference in cost-per-part rarely appears in foundry quotes, which typically list only the upfront pattern price.

From a sourcing perspective, this gap explains why pattern lifespan varies 10x to 100x between materials – and why upfront cost is a poor predictor of total tooling cost. When evaluating foundry quotes, calculating the cost per casting over your expected production run matters far more than comparing pattern prices.

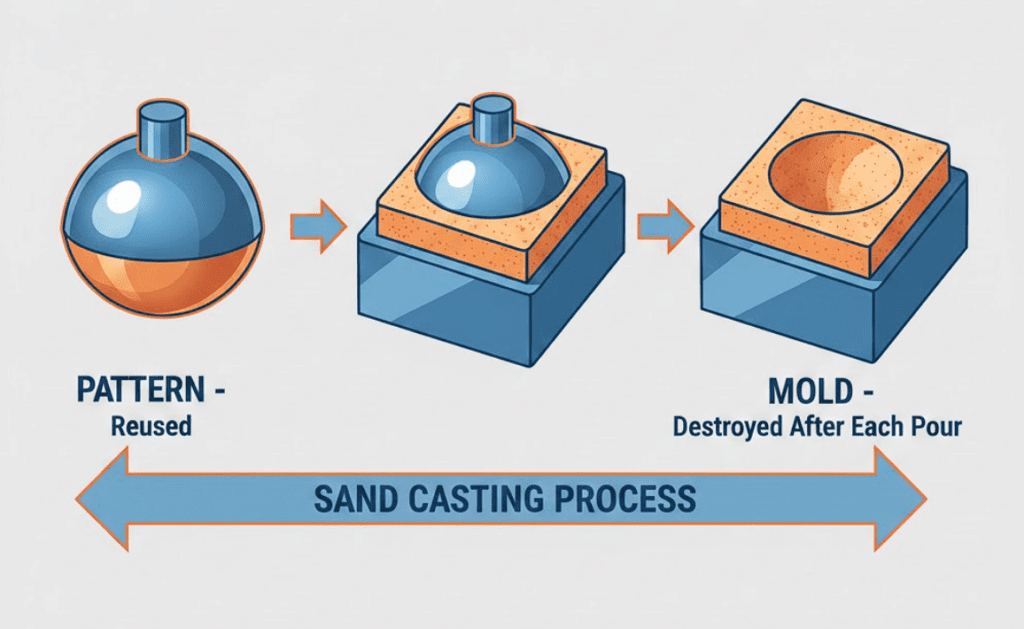

In sand casting, the sand mold is destroyed after every pour. The pattern – the tool used to create that mold cavity – is what potentially gets reused.

This distinction trips up many buyers who ask about “mold lifespan.” Sand molds have no lifespan; they are expendable by design. The economic question is really about pattern durability: how many molds can one pattern produce before it degrades beyond acceptable tolerances?

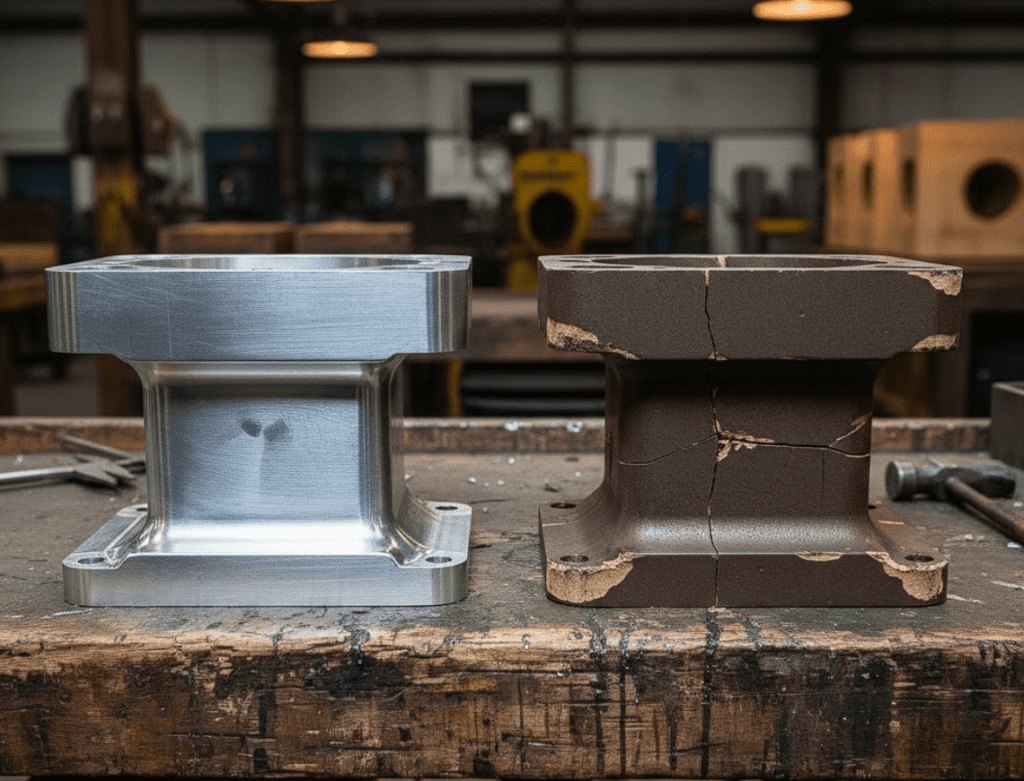

Pattern material selection drives long-term tooling economics. A wood pattern and an aluminum pattern create identical molds on day one. By cycle 500, the wood pattern may show wear that affects casting dimensions. The aluminum pattern will run unchanged past 50,000 cycles.

Pattern making materials span a wide durability range.

Wood patterns suit prototyping and very low-volume production – roughly 50 pieces or fewer per year. Traditional pattern shops used straight-grained mahogany finished with lacquer to maximize durability, but even premium wood patterns degrade relatively quickly depending on part complexity and handling care.

Wood’s advantage is cost: $500 to $2,000 for most patterns. Its limitation is fragility. Draft angles, sharp corners, and parting line features wear quickly. I recommend wood only when you are certain total lifetime production will stay under a few hundred units.

Polyurethane and tooling board materials bridge the gap between wood and metal. Industry estimates suggest tooling life around 5,000 units for polyurethane board patterns.

Tooling board costs approximately 15-20% less than aluminum. However, once you add steel wear strips, lifting eyes, and brass inserts to extend the pattern’s service life, costs creep toward aluminum pricing while durability remains inferior. This “savings trap” catches many procurement teams who focus on initial quotes.

Aluminum patterns dominate medium to high-volume production. With tool life typically ranging from 50,000 to 100,000 units, aluminum outlasts polyurethane by 10-20x.

The durability gap comes not just from sand wear but from handling. As one tooling specialist noted, polyurethane board and aluminum show similar wear resistance from sand contact, but polyurethane chips and breaks from handling while aluminum does not. Every time a pattern moves between storage, setup, and production, handling damage accumulates – and metal patterns shrug off impacts that crack plastic tooling.

For the highest volumes, steel or iron patterns push cycle life to 100,000-1,000,000 units, though these applications typically serve automotive or appliance production runs.

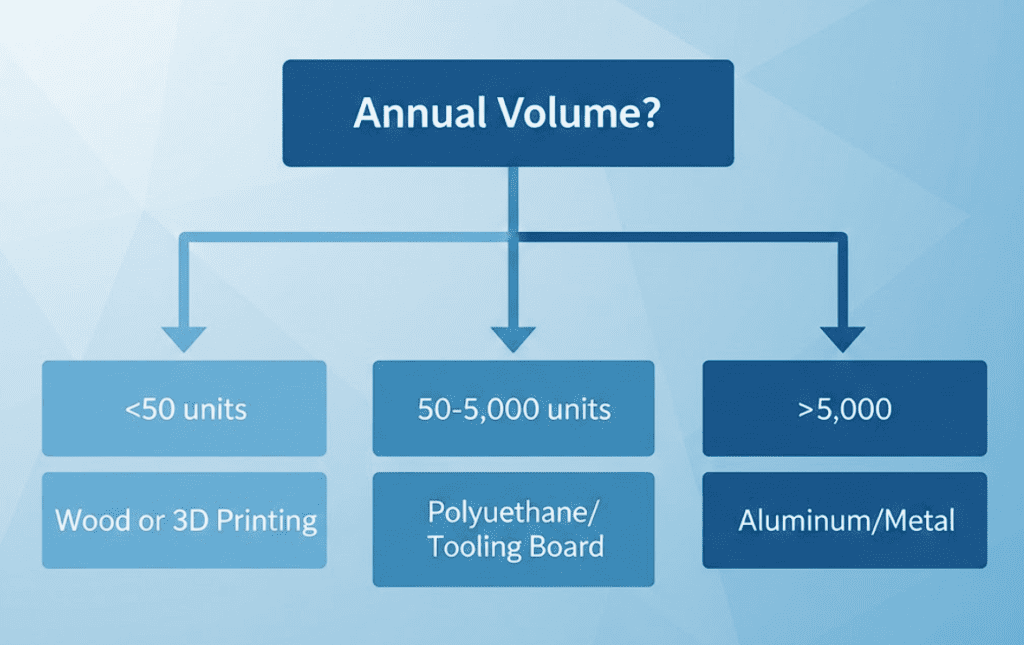

The rule of thumb from industry: plastic tooling works for castings with annual volumes up to 5,000 pieces. For volumes over 5,000 pieces annually, metal patterns become the economical choice.

This 5,000-piece threshold is more specific than the vague “high volume” guidance most foundries offer. Brad Moore, Director of Sales Engineering at Badger Alloys, frames it as “estimated annual usage (EAU) driven selection” – the more times the pattern will be used, the harder the material required.

Many engineers assume the break-even point sits higher, perhaps at 10,000 or 20,000 units. They underestimate how quickly soft patterns degrade and how maintenance costs compound. At 5,000 annual units, the amortization math already favors aluminum.

For volumes under 50 pieces per year, wood patterns remain appropriate. Between 50 and 5,000 pieces, polyurethane or tooling board can work – but factor in potential replacement costs and the hidden expenses of reinforcing a soft pattern to survive production handling.

Total tooling cost equals upfront pattern cost plus replacement costs plus maintenance over the production run. Here is how that calculation looks for a typical part:

Wood pattern scenario:

Aluminum pattern scenario:

The aluminum pattern costs 3x more upfront but delivers tooling cost savings of 70% over the production run. Scale this to 50,000 units, and wood would require roughly 100 replacements versus zero for aluminum – around $100,000 in wood patterns versus $3,000 in aluminum.

The tooling board “15-20% savings” trap becomes clear in this light. Saving $500 on initial tooling means nothing if the pattern needs replacement twice during production, adding $2,000-3,000 in unplanned costs plus production delays.

3D sand printing has changed the economics for low-volume and prototype casting. Direct printing of sand molds eliminates pattern investment entirely.

Standard 3D sand printing rates run approximately $0.13 per cubic inch for printed molds and cores. A Voxeljet case study documented a foundry producing complex turbine wheel cores where conventional production cost approximately EUR 3,600 per batch. 3D printing reduced this to EUR 900 – a 75% savings.

For production runs under approximately 45-100 units (varying by part complexity), 3D sand printing often beats any pattern investment. The crossover point depends on part size and geometry, but the principle holds: sometimes the best pattern investment is no pattern at all.

I recommend 3D printing consideration for any job under 50 units or any prototype run. Above that threshold, run the cost-per-cycle math to compare traditional pattern options.

The pattern that costs half as much but lasts one-tenth as long is not cheaper – it costs ten times more per casting.

For volumes under 50 units, consider 3D sand printing or accept wood pattern costs as tooling expense. Between 50 and 5,000 annual units, evaluate polyurethane with realistic replacement assumptions. Above 5,000 units annually, aluminum patterns nearly always deliver the lowest cost per casting.

Calculate cost-per-cycle before comparing foundry quotes. That single metric reveals whether a “cheaper” pattern option actually saves money over your production run.