Failing to plan for secondary operations can sharply increase your project cost. I’ve seen buyers add 30% to their budget after realizing their sand casting needed machining, heat treatment, and coating that wasn’t in the original quote.

Most sand castings don’t ship as-cast. Secondary operations transform a rough casting into a functional component with the right dimensions, mechanical properties, and corrosion protection. Before designing your pattern, consider which operations you’ll need and build them into your specifications from the start.

Machining removes the intentional excess material left on castings to achieve final dimensions and surface quality. Sand casting produces the roughest surfaces among casting processes—250 to 900 RMS (6.3 to 22.5 um Ra)—so any surface requiring precision fit or sealing needs machining.

Machining allowance by casting size:

| Casting Type | Surface | Allowance |

|---|---|---|

| Small castings | External faces | 2-5 mm |

| Standard sand casting | External faces | 3 mm |

| Standard sand casting | Internal bores | 2 mm radially |

| Large castings | All surfaces | Up to 25 mm |

| Steel castings | Variables dependent | 4.8-19 mm (3/16″ to 3/4″) |

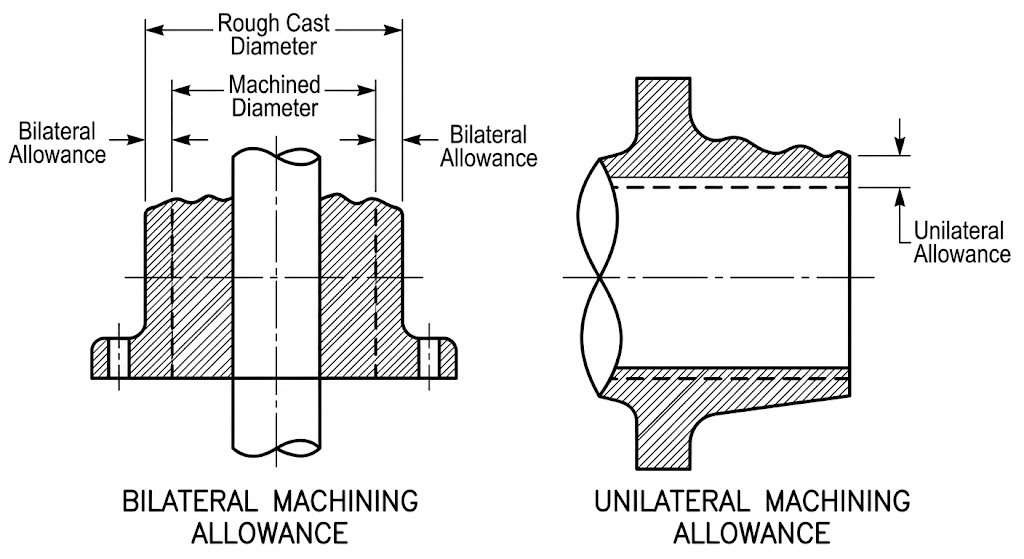

The machining allowance should account for whether the dimension is bilateral or unilateral. For rotating parts like shafts or bores, allowance applies to both sides of the diameter. For flat faces, it’s one direction only.

One rule I always emphasize: on your first machining cut, stay at least 1.5 mm (1/16 inch) below the cast surface. This ensures you’re cutting clean metal, not the decarburized or sand-affected layer that exists on every casting surface.

My recommendation for first-time castings with a new foundry: add 20% to the minimum machining allowance. It’s far cheaper than scrapping parts that came up short.

Heat treatment modifies the mechanical properties of your casting—strength, hardness, ductility, and internal stress. The specific heat treatment processes you need depend on your alloy and application requirements.

Aluminum sand castings commonly receive T5, T6, or T7 treatment. T6 is the most popular because it delivers the best strength improvement.

| Temper | Process | Temperature | Time | Result |

|---|---|---|---|---|

| T5 | Artificial aging | 227C (440F) | 3-5 hours | 23 ksi tensile, 45-75 HB |

| T6 | Solution + age | 538C + 154C | 12h + 3-5h | 34 ksi tensile, 70-105 HB |

| T7 | Overaging | 538C + 227C | 12h + 7-9h | 31 ksi tensile, 60-90 HB |

T6 heat treatment increases A356 aluminum casting strength by 30-40% compared to the as-cast condition. That’s a jump from 23 ksi to 34 ksi tensile strength—a meaningful gain for structural applications.

Gray and ductile iron castings use different treatments depending on whether you need stress relief, improved machinability, or specific mechanical properties.

| Process | Temperature | Time | Purpose |

|---|---|---|---|

| Stress relief | 500-550C (930-1020F) | 2-8 hours | Removes 90-95% internal stress |

| Ferritizing anneal | 700-760C (1300-1400F) | Varies | Improves machinability |

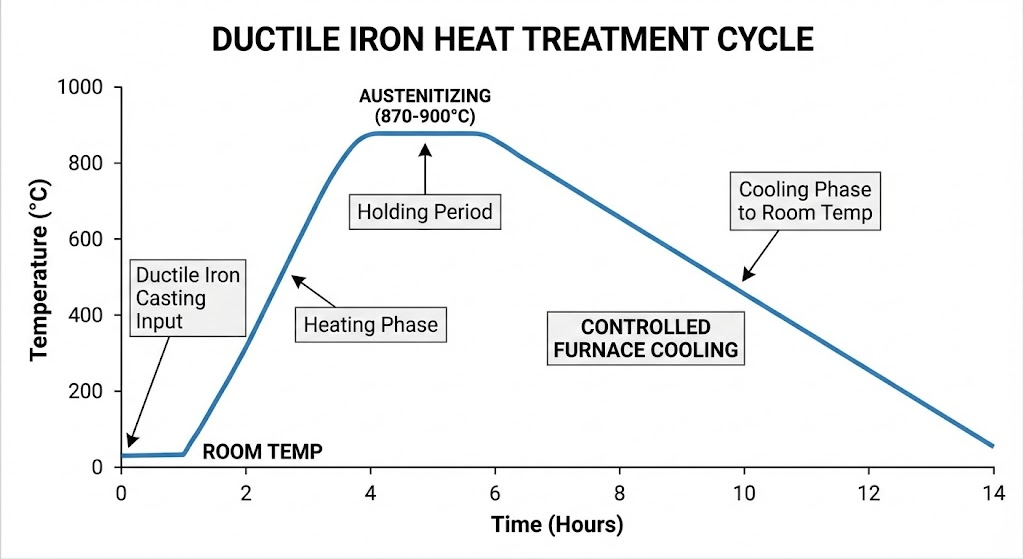

| Full anneal (ductile) | 870-900C (1600-1650F) | 1 hour/inch | ASTM A536 Grade 60-40-18 |

| Normalizing | 950-980C | Varies | ASTM A536 Grade 100-70-03 |

Stress relief at 500-550C for 2-8 hours removes 90-95% of internal stress from iron castings. This is essential for dimensionally critical parts that will be machined, as residual stress causes distortion during metal removal.

Always specify the cooling rate, not just temperature and time. Furnace cooling, air cooling, and quenching produce very different results from the same hold temperature.

As-cast surface finishing from sand casting ranges from 250 to 900 RMS, depending on sand grain size, alloy, and section thickness. Shell sand casting achieves finer finishes of 75 to 150 RMS.

| Process | Surface Finish (RMS) | Ra Equivalent |

|---|---|---|

| Sand casting (general) | 250-900 | 6.3-22.5 um |

| Shell sand casting | 75-150 | 1.9-3.8 um |

| Permanent mold (comparison) | 200-420 | 5.0-10.5 um |

Post-casting finishing options include:

Protective coatings extend casting life in corrosive environments:

Specify surface finish requirements by functional feature, not as a blanket Ra value. A mounting face may need 3.2 um Ra for sealing, while a non-functional surface can remain as-cast. Feature-specific callouts save machining cost.

The order of secondary operations affects both cost and quality. Heat treatment before or after machining is the most common sequencing decision.

Pre-machining heat treatment:

Post-machining heat treatment:

My guidance: if your tolerance is tighter than +/-0.25 mm, machine after heat treatment. For looser tolerances, heat treat first and machine the hardened material to reduce distortion risk.

When requesting quotes, include these specifications for each secondary operation:

Machining:

Heat treatment:

Coating/finishing:

Get your foundry’s input on operation sequencing before finalizing specifications. Foundries with in-house machining and heat treatment can optimize the workflow. Those outsourcing secondary operations may have different constraints that affect your quality and lead time.

Complete secondary operation specifications prevent the cost surprises that derail casting projects. Before sending your RFQ, verify you’ve addressed: machining allowances and surface finish requirements for all critical features, heat treatment parameters with testing criteria, and coating specifications with coverage definitions. Skip any item and you invite change orders after production starts.