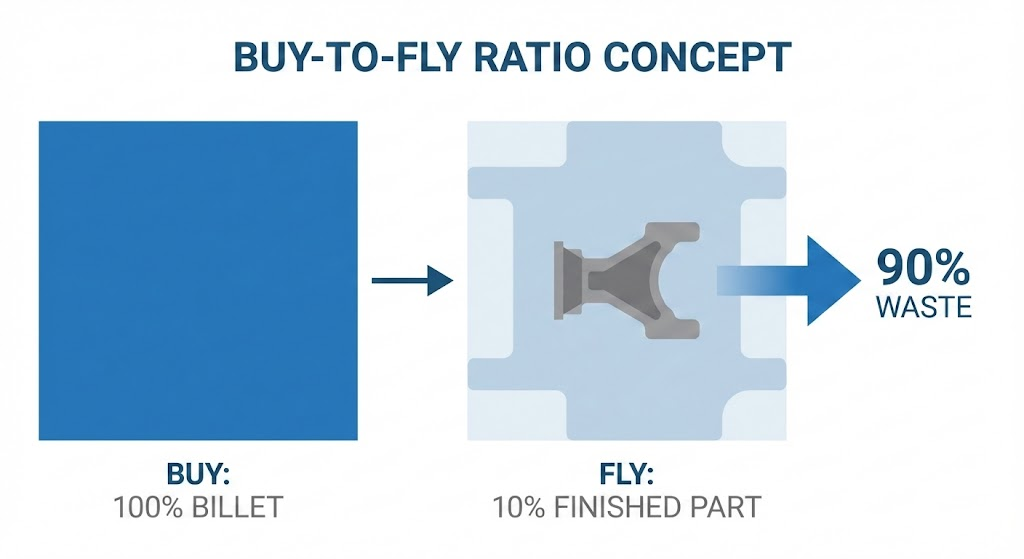

Aerospace manufacturers routinely waste 90% of the titanium they buy. A 650 kg aluminum billet becomes a 20 kg structural rib—32 kg scrapped for every kg that flies. When material removal reaches these levels, the volume-based rules for choosing between sand casting and machining from solid fall apart.

The conventional wisdom says casting makes sense at 10,000+ units. That threshold ignores what actually drives cost: how much material you cut away. The buy-to-fly ratio—starting material weight divided by finished part weight—tells you more about the right manufacturing method than production volume ever will.

Buy-to-fly ratios of 10:1 are common in aerospace applications. That means only 10% of the purchased material ends up in the final part. At typical titanium prices of $15-30 per pound, the math becomes brutal: you’re paying full price for metal that goes straight to the recycling bin.

From a sourcing perspective, this changes everything about the casting versus machining calculation. A part with 80% material removal at 100 units can cost more to machine than a part with 20% removal at 1,000 units. The volume threshold everyone quotes assumes moderate material removal—an assumption that fails for complex hollow structures, ribbed components, and anything with internal features.

Consider what happens when removal percentages climb. At 50% removal, machining remains competitive for most geometries. At 70%, the machine time starts dominating the cost structure. Above 80%, you’re often paying more for cutting than for the material itself. This is where the break-even point drops from thousands of units to dozens.

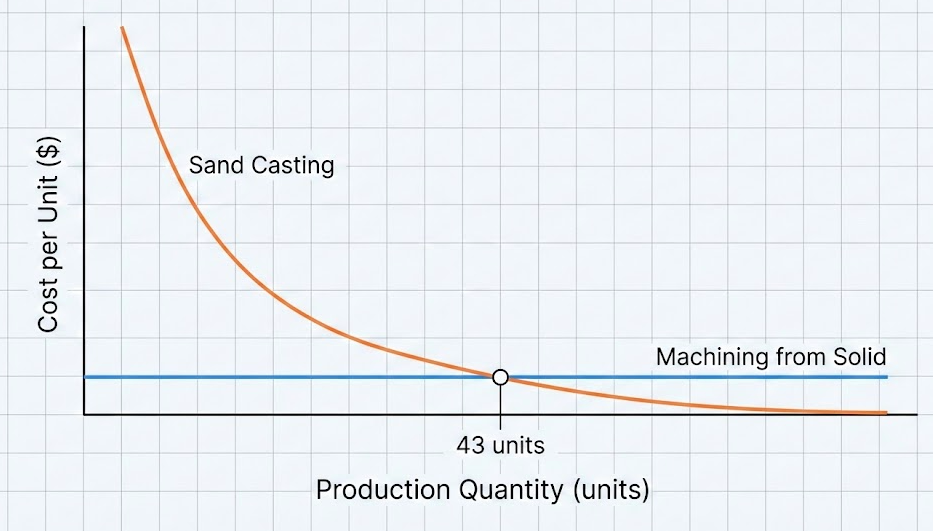

Grenzebach’s motor flange case study demolished the 10,000-unit myth. Their design-to-cost analysis compared sand casting against pure CNC machining for a drivetrain component. Casting became more cost-effective at just 43 units.

The numbers explain why. Machining required a 10.2 kg blank to produce a 1.7 kg finished part—83% material removal. The cast version started at 2.0 kg and finished at 1.5 kg, achieving 75% material utilization compared to machining’s 17%. Material efficiency jumped fivefold, and machining time dropped by half since the cast blank was already near-net-shape.

For parts with high material removal, the break-even point typically falls between 40 and 100 units rather than the commonly cited 10,000+ threshold. The exact number depends on your geometry, material cost, and local shop rates, but the principle holds: when you’re removing more than 60% of your starting material, run the casting math even for low-volume projects.

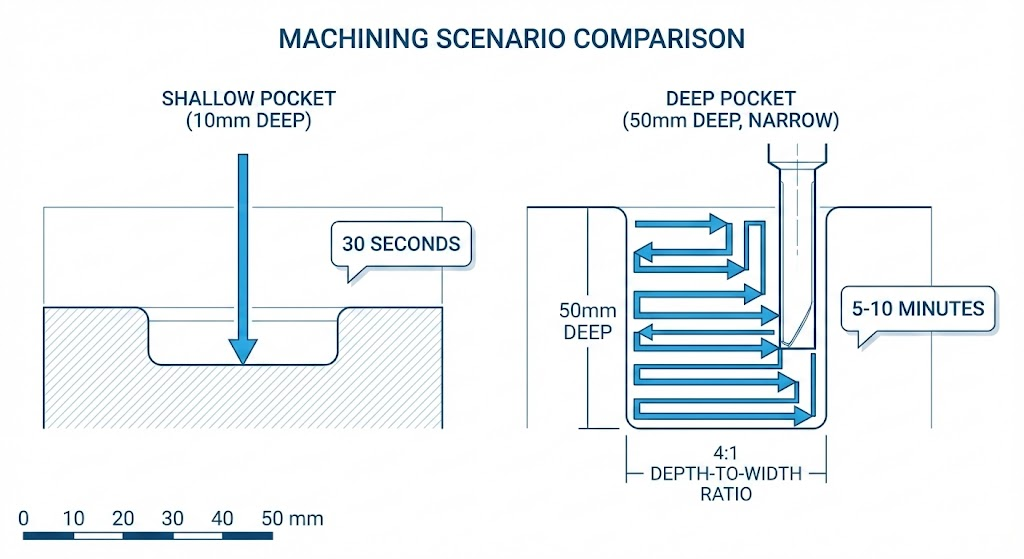

Part geometry can multiply machining costs faster than any other factor. A simple 10mm hole takes 30 seconds to drill. A 50mm deep pocket might take 5-10 minutes depending on tooling and step-downs. That time difference compounds across every feature on your part.

The standard rule limits pocket depth to four times the tool diameter—a 1/4″ wide pocket should stay no deeper than 1″. Go beyond that ratio and you’re into specialty tooling, multiple passes, and much longer cycle times. One manufacturer cut cycle time by 30% just by adjusting pocket depths, saving thousands across the production run.

Internal undercuts and hollow sections amplify the problem. Castings can incorporate weight-saving features that would be impractical to machine: hollowed webs, undercut ends, and complex internal passages. These features are straightforward in a mold cavity but require either multi-axis setups or impossible tool access when machining from solid. If your part has features a cutting tool can’t reach, casting isn’t just cheaper—it’s the only viable option.

Machining keeps its advantages in specific scenarios. Prototypes and development parts need days, not the 4-6 weeks required for casting tooling. When you need one part by Friday, no foundry can help.

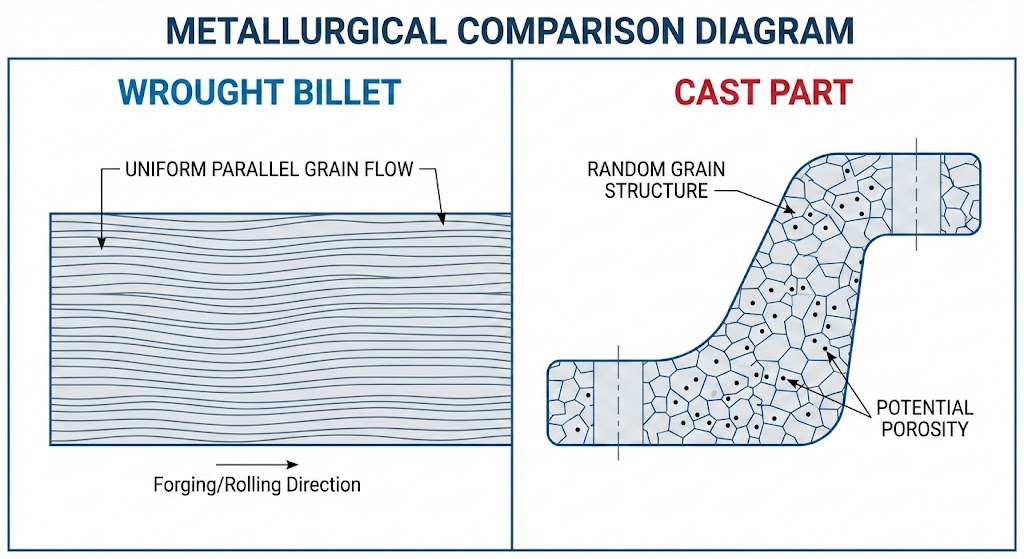

Billet materials offer superior mechanical properties for strength-critical applications. Wrought metal has consistent grain structure without the porosity risks that come with casting. For simple shapes where material removal stays below 50%, the property advantages can justify the waste.

Tight tolerances also favor machining. Sand casting typically achieves +/- 0.5mm at best, while machining holds +/- 0.025mm routinely. Parts requiring extensive post-casting machining may see the cost advantage disappear—you’re paying for casting and machining.

The break-even point depends on these factors working together. A simple cylindrical part with 30% material removal that needs +/- 0.1mm tolerance and ships next week should be machined. A complex housing with 75% removal, +/- 1mm tolerance, and a three-month delivery window should be cast.

Start with your buy-to-fly ratio, not your production volume. Calculate the material removal percentage by comparing your finished part weight to the smallest billet that could contain it.

Above 70% material removal, casting deserves serious consideration regardless of volume. Add geometry complexity—deep pockets, internal features, undercuts—and the threshold drops further. The Grenzebach case hit break-even at 43 units with 83% removal, and your numbers might be similar.

Run the full cost comparison: raw material, machine time at $75-130/hour for 5-axis work, tooling for both processes, and post-processing requirements. Sand casting patterns run $6,000-20,000 while die casting molds hit $60,000-500,000—but sand casting works at volumes where die casting tooling never pays off.

The question isn’t whether to cast or machine. The question is how much metal you’re planning to throw away.