The quoted piece price represents only 60-70% of your actual casting cost. The rest hides in tooling amortization, scrap rates, secondary machining, and inventory carrying costs. The conventional wisdom says choose sand casting for volumes under 500 pieces and permanent mold casting above that threshold. That rule works for quick estimates but fails for serious sourcing decisions.

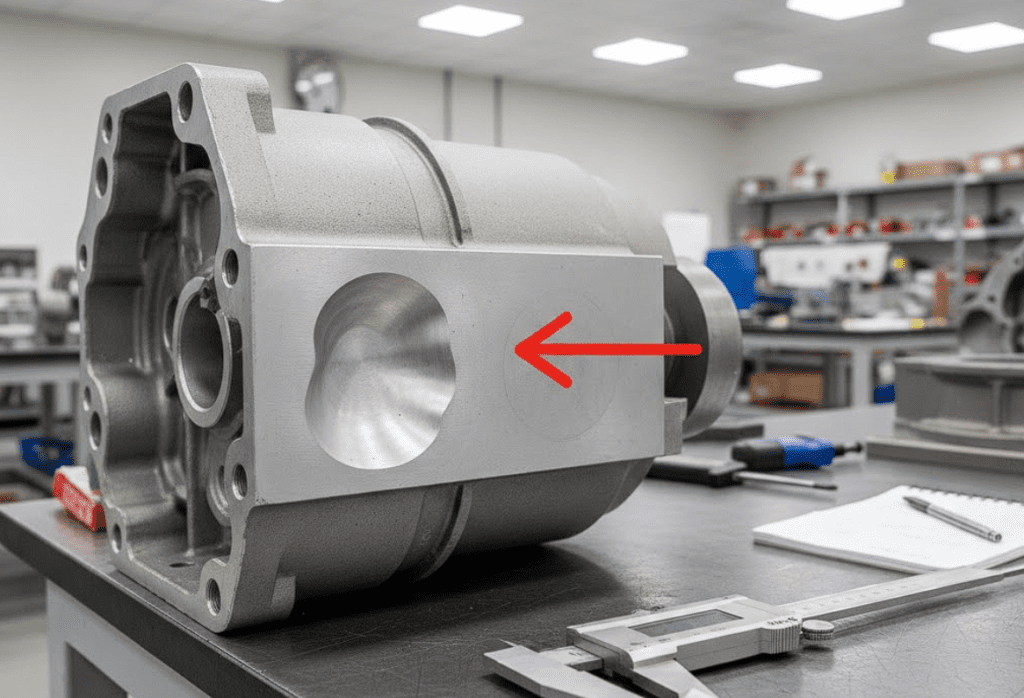

Total cost of ownership determines the right process, not annual quantity alone. A 1,000-piece order with tight tolerances requiring heavy machining may favor sand casting. A 300-piece order with as-cast requirements may justify permanent mold tooling. This guide covers the selection criteria that actually matter: tooling economics, quality costs, lead times, and a practical decision framework.

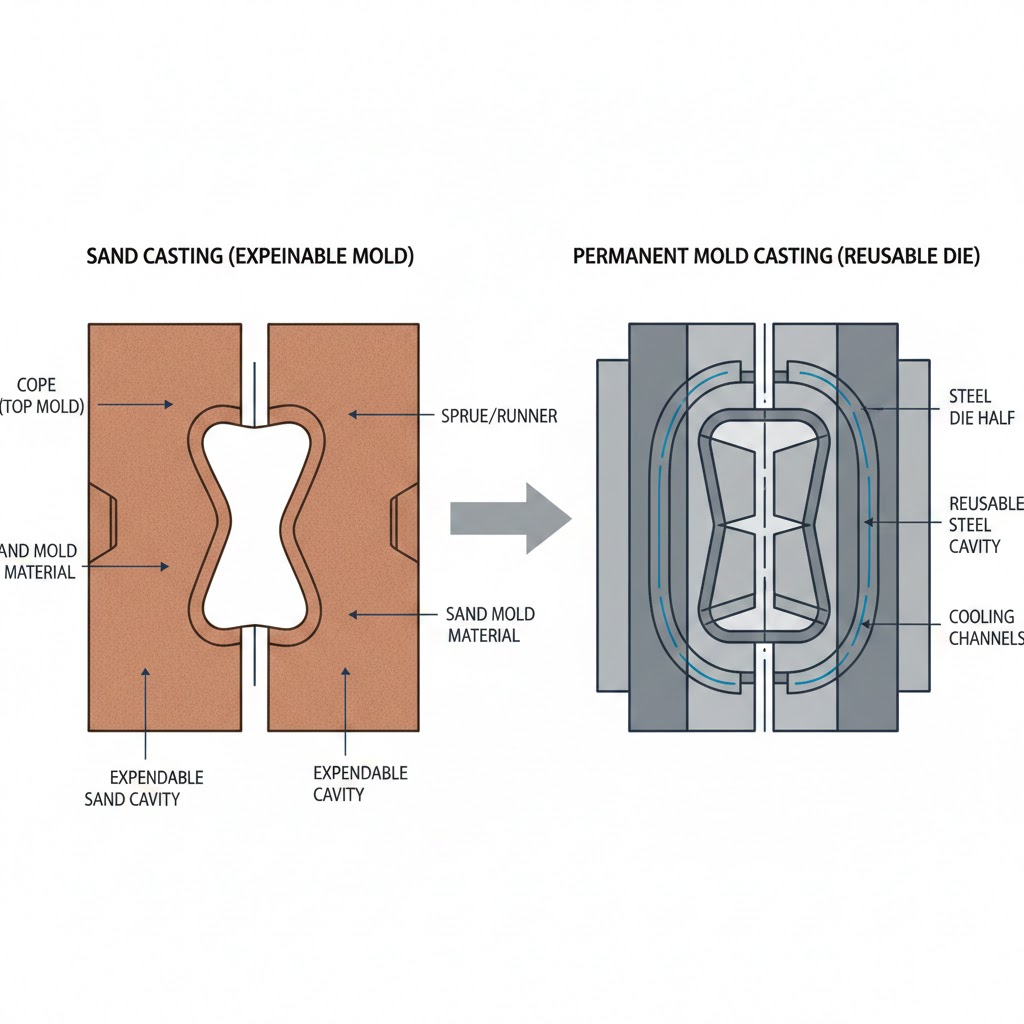

Sand casting tooling costs $6,000 to $20,000 for typical patterns and core boxes. Permanent mold tooling runs $10,000 to $90,000 depending on part complexity and cavity count. That 3-5x difference in upfront investment changes everything about your break-even calculation.

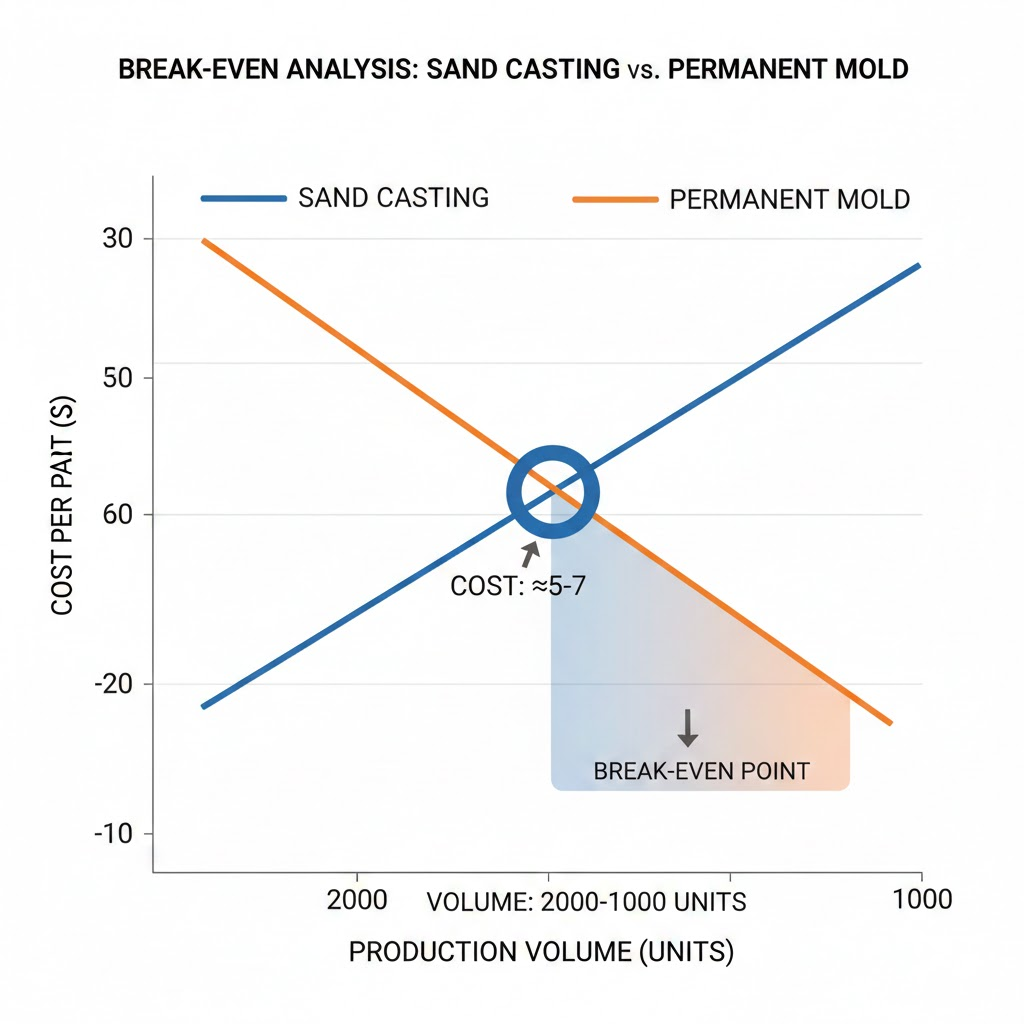

The simple “500 pieces = switch to permanent mold” threshold ignores tooling amortization math. Batesville Products notes that permanent mold delivers best ROI at moderate volumes, but “moderate” varies dramatically by part. Industry data shows actual break-even points ranging from 2,000 to 10,000 pieces depending on die cost and part complexity. A simple housing might break even at 2,500 units. A complex manifold with multiple cores might not break even until 8,000 units.

Permanent mold tooling lasts approximately 60,000 parts before requiring refurbishment or replacement. If your lifetime volume exceeds that threshold, factor in tooling replacement costs. If your product lifecycle is uncertain, that $50,000 mold represents significant risk.

From a sourcing perspective, I recommend calculating amortized tooling cost per piece at three volume scenarios: your expected annual usage, 50% of that, and 150%. If permanent mold only wins at the optimistic scenario, sand casting offers better risk-adjusted economics.

Tooling cost comparison:

| Factor | Sand Casting | Permanent Mold |

|---|---|---|

| Tooling cost | $6,000-$20,000 | $10,000-$90,000 |

| Tooling life | Single-use pattern | ~60,000 parts |

| Break-even point | N/A | 2,000-10,000 pieces |

| Modification cost | $500-$2,000 | $5,000-$15,000 |

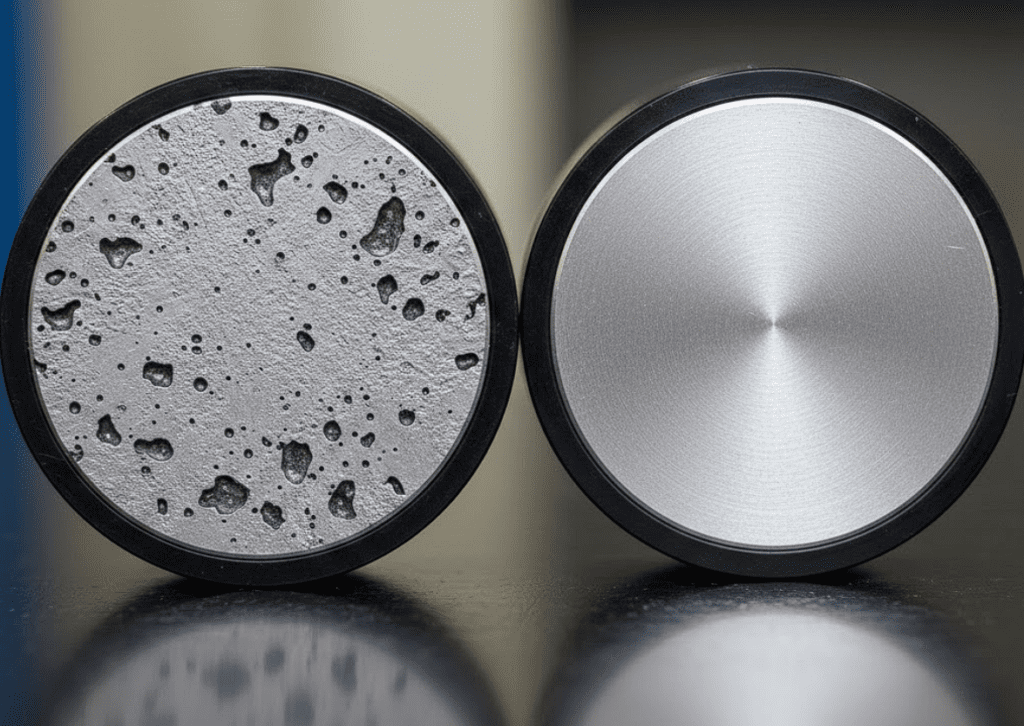

Permanent mold casting delivers tighter tolerances: 0.015 inches for the first inch plus 0.002 inches per additional inch, compared to 0.030 inches plus 0.002 inches for sand casting. Surface finish runs 200-420 RMS for permanent mold versus 300-560 RMS for sand. These differences matter for pressure-tight applications and cosmetic surfaces.

The real quality differentiator is porosity. Sand casting typically produces 2-5% porosity rates; permanent mold keeps porosity under 1%. For pressure containment or fatigue-critical applications, that difference is decisive.

However, quality costs extend far beyond these specifications. Scrap rates tell the real story: sand foundries typically run 6-10% scrap, while permanent mold achieves under 1%. One military contractor discovered this the hard way when their sand-cast gearboxes showed 50% scrap due to shrinkage porosity visible only after final machining. Process optimization eventually reduced scrap to 2%, but not before quality costs dwarfed any per-piece savings.

Don’t compare quoted piece prices without understanding scrap expectations. A $50 sand casting with 8% scrap and rework actually costs $54+ per delivered good part. A $55 permanent mold casting with 1% scrap costs $55.55. The “cheaper” process becomes more expensive when quality costs enter the calculation.

Quality comparison:

| Metric | Sand Casting | Permanent Mold |

|---|---|---|

| Linear tolerance (first inch) | 0.030″ | 0.015″ |

| Surface finish (RMS) | 300-560 | 200-420 |

| Typical porosity | 2-5% | <1% |

| Typical scrap rate | 6-10% | <1% |

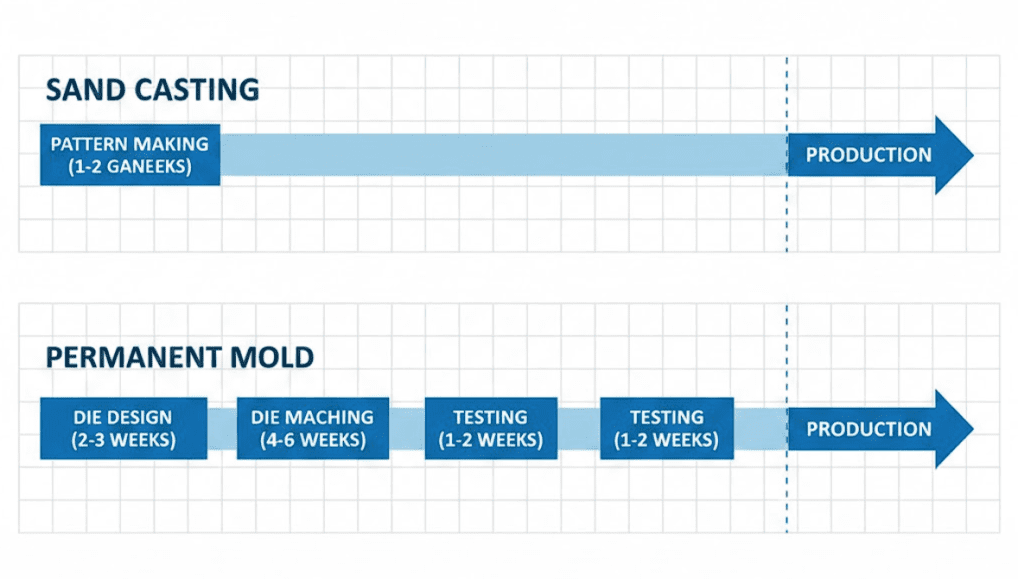

Sand casting tooling requires 1-4 weeks to produce. Permanent mold tooling takes 6-12 weeks to machine and test. For new product introductions or design iterations, that 2-3 month difference drives process selection regardless of unit economics.

Once tooling exists, the equation reverses. Sand casting cycles run 30-60 minutes per part. Permanent mold cycles complete in 1-5 minutes. For steady-state production of thousands of units, permanent mold’s faster throughput reduces inventory carrying costs and improves delivery flexibility.

This creates a strategic choice based on demand pattern. Early-stage products with uncertain demand favor sand casting’s flexibility: lower tooling investment, faster design changes, acceptable economics at lower volumes. Mature products with stable demand favor permanent mold’s consistency: lower per-piece cost, faster production cycles, tighter quality control.

Consider how lead time affects your inventory strategy. With 6-12 week permanent mold tooling lead times, you need to forecast demand further ahead. Sand casting’s 1-4 week tooling allows more responsive production planning. If your demand is seasonal or unpredictable, the flexibility premium of sand casting may outweigh permanent mold’s per-piece savings.

Lead time comparison:

| Stage | Sand Casting | Permanent Mold |

|---|---|---|

| Tooling production | 1-4 weeks | 6-12 weeks |

| Production cycle | 30-60 min/part | 1-5 min/part |

| Design change turnaround | Days to weeks | Weeks to months |

The volume threshold approach fails because it treats all parts and situations identically. Here’s a more useful framework based on total cost of ownership.

Choose sand casting when:

Choose permanent mold when:

The gray zone (500-2,000 pieces): This is where TCO analysis matters most. Calculate total cost including tooling amortization, estimated scrap and rework, secondary machining requirements, and inventory carrying costs. The process with lower TCO wins, regardless of volume.

Experienced engineers on technical forums recommend a flexible approach: “Rather than committing to hard tooling prematurely, develop interchangeable part designs optimized for different processes and obtain comparative quotes for various production volumes.” This lets you pivot if demand differs from projections.

The right casting process is the one with lowest total cost of ownership for your specific situation. Don’t let a supplier’s preference or a simple volume threshold make this decision for you.

Start with three questions: What’s my realistic lifetime volume? What quality level do I actually need? How certain is my demand forecast? The answers point toward sand casting flexibility or permanent mold consistency.

When in doubt, request quotes for both processes at multiple volume scenarios. The comparison reveals which cost factors dominate your specific application. That analysis beats any rule of thumb.