Grinding is a precision machining process that uses a rotating abrasive wheel to remove material from a workpiece.

Unlike single-point cutting tools, each abrasive grain acts as a small cutting edge, gradually shearing away microscopic chips.

Different grinding methods vary in how the workpiece and wheel move relative to each other, the type of wheel used, and the geometry of the surface being produced.

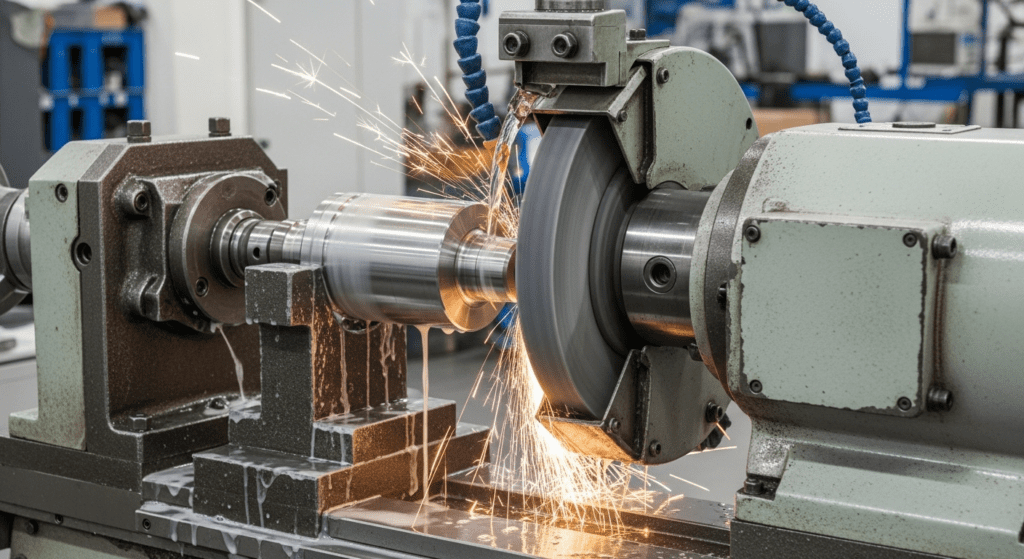

External cylindrical grinding is a process in which the outer surface of a cylindrical workpiece is ground while the workpiece is supported between centers or in a chuck.

The workpiece rotates around its axis while the grinding wheel, mounted parallel to the work axis, feeds either radially into the part (plunge grinding) or traverses along its length (traverse grinding).

The grinding wheel and the workpiece typically rotate in opposite directions to ensure a shearing action, and multiple passes are taken until the final diameter is reached.

Internal cylindrical grinding removes material from the internal surface of a bore using a small-diameter grinding wheel mounted on a high-speed spindle.

The workpiece, usually held in a chuck or collet, rotates while the grinding wheel is inserted into the bore and moves axially along its length.

Radial in-feed controls the final size, and the wheel may be swiveled for tapered bores or dressed to specific profiles.

Centerless grinding is a method where the workpiece is supported externally between a high-speed grinding wheel and a slower-speed regulating wheel, with a workrest blade underneath.

The centerline of the workpiece is positioned above the centerline of the two wheels, which helps maintain its rotation and grinding geometry.

The regulating wheel controls the rotation and feed of the workpiece, while the grinding wheel removes material.

Two main modes are used:

Surface grinding is the process of producing flat or contoured surfaces by moving a workpiece under a rotating abrasive wheel.

The grinding wheel is mounted on a spindle, which can be oriented horizontally (cutting with the wheel’s periphery) or vertically (cutting with the wheel’s face).

The workpiece is held securely on the machine table using a magnetic chuck, vacuum fixture, or mechanical clamp, and the table moves in a controlled reciprocating or rotary motion beneath the wheel.

Creep-feed grinding is a deep-cutting process in which the grinding wheel removes a large amount of material in a single slow feed pass.

Instead of multiple shallow passes, the wheel is dressed to the required shape and fed into the workpiece at depths of several millimeters, with the table feeding very slowly under the wheel.

This method requires a rigid, high-power machine and often uses continuous dressing to maintain the wheel’s cutting profile.

Tool and cutter grinding is the process of sharpening, reconditioning, or manufacturing precision cutting tools using a specialized multi-axis grinding machine.

The tool is mounted in a workhead that can be swiveled and tilted, allowing the wheel to access various surfaces and angles of the tool.

Multiple wheel shapes and profiles may be used to grind flutes, relief angles, or complex cutting edges, and the wheel is dressed to the required geometry before each operation.

Contour grinding shapes a workpiece surface into a specific curve or profile by using a grinding wheel dressed to the desired form or by following a CNC-programmed path.

The wheel may be dressed with a diamond roll or other profiling device to match the exact contour required.

During grinding, the wheel and workpiece move in a controlled path so that the ground surface matches the intended shape precisely, whether it is a smooth curve, angular surface, or a combination.

Gear grinding is the process of finishing gear teeth by precisely removing material from their flanks with a synchronized grinding wheel.

The machine coordinates the rotation of the gear blank and the grinding wheel so that the wheel’s motion follows the intended tooth geometry.

Two methods are common:

Thread grinding is a process for forming screw threads with a grinding wheel instead of a cutting tool.

The grinding machine synchronizes the rotation of the workpiece with the axial feed of the grinding wheel so that the wheel traces the desired thread helix.

Jig grinding is a precision process for finishing holes, contours, or complex shapes with a high-speed, small-diameter grinding wheel mounted in a vertical spindle.

The workpiece is mounted on a precise X–Y table, allowing exact positioning of the grinding wheel over the desired feature.

The spindle can be adjusted for height, and the wheel can be dressed to specific shapes, enabling extremely accurate form and positional grinding.

Form grinding is a method where the grinding wheel is dressed to a specific profile, which is then transferred directly to the workpiece during grinding.

The wheel maintains this profile throughout the operation, and both the workpiece and wheel move in a controlled path so that the resulting surface matches the wheel’s shape exactly.

This technique is used for producing complex forms that cannot be generated by standard traverse or plunge grinding motions.