Choosing the right material for investment casting determines whether your part succeeds or fails. The difference between stainless steel and aluminum isn’t just weight—it’s whether your component survives 1000°C heat, resists seawater corrosion, or machines easily after casting.

Investment casting works with virtually any metal alloy, from affordable carbon steel to exotic superalloys that cost more per pound than silver. Each material category brings specific strengths and weaknesses that directly impact performance, manufacturing cost, and service life.

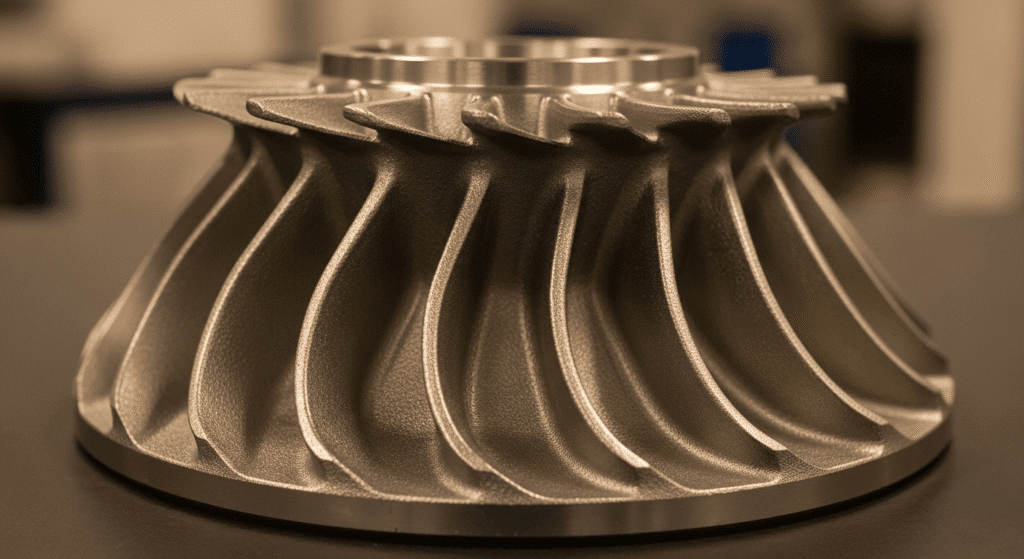

You need to match material properties to your application requirements. A jet turbine blade requires nickel superalloys that maintain strength at temperatures that would melt aluminum. A medical implant demands titanium’s perfect biocompatibility. A pump impeller might need bronze’s combination of corrosion resistance and anti-galling properties.

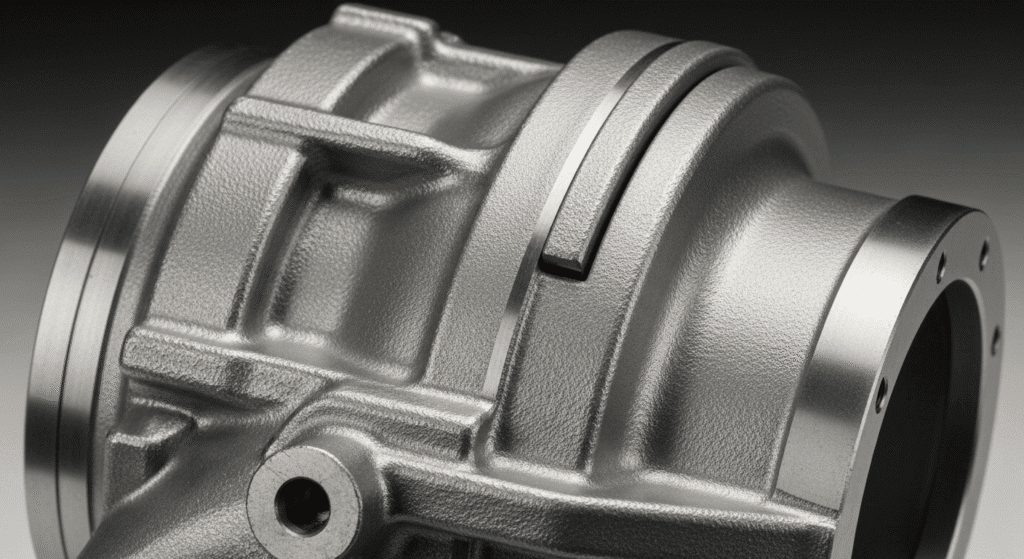

Stainless steels combine high strength with exceptional corrosion resistance, making them the go-to choice for parts that face harsh environments. All stainless steels contain at least 10.5% chromium, which creates a protective oxide layer that prevents rust formation.

These alloys achieve tensile strengths ranging from 500 MPa in austenitic grades like 304 to over 1300 MPa in precipitation-hardening grades like 17-4 PH after heat treatment. The material maintains this strength even at moderately high temperatures, with certain grades performing well up to 800°C.

The corrosion resistance comes from that chromium-oxide layer, which self-heals when scratched or damaged. This means stainless parts often need no protective coatings, even in marine or chemical environments.

Stainless steel’s toughness varies by grade. Austenitic stainless steels (like 316) offer excellent ductility and impact resistance, while martensitic grades provide higher hardness but less flexibility.

The main trade-off is machinability. Stainless steel work-hardens during cutting, making it tougher to machine than carbon steel and requiring specialized tooling.

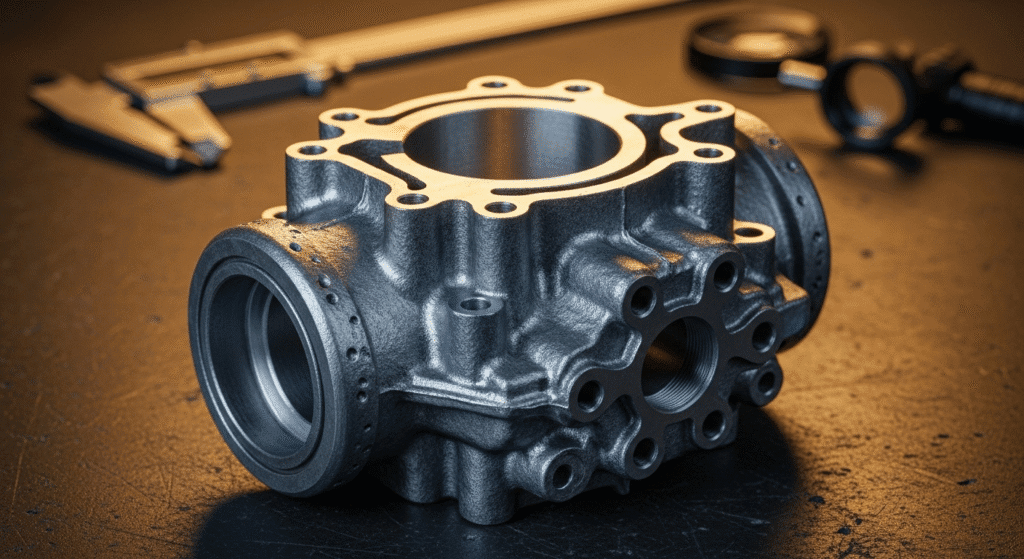

Carbon steels deliver high strength at the lowest cost of any casting metal, with properties that you can customize through heat treatment. These iron-carbon alloys contain 0.1% to 1.0% carbon, with low-alloy versions adding small amounts of chromium, molybdenum, or nickel.

Medium-carbon steel castings typically reach yield strengths of 400-800 MPa after heat treatment. You can further boost hardness through quenching and tempering, creating wear-resistant surfaces while maintaining a tough core.

These steels machine easily, especially in lower carbon grades. The material cuts cleanly, drills well, and welds readily—making post-casting operations straightforward and economical.

Carbon steels have excellent thermal conductivity and magnetic properties. This makes them perfect for electrical motor components and applications where heat dissipation matters.

The biggest limitation is corrosion. Without protective coatings, carbon steel rusts quickly when exposed to moisture or chemicals.

High-carbon steels can also become brittle if not properly tempered, risking catastrophic failure under impact loads.

Aluminum alloys offer the best strength-to-weight ratio among common casting metals, weighing just one-third as much as steel. Popular casting alloys like A356 combine aluminum with silicon and magnesium to achieve tensile strengths of 150-300 MPa.

The low melting point of 660°C makes aluminum easier to cast than ferrous alloys. It flows readily into thin sections and complex geometries, allowing intricate designs that would be impossible with other metals.

Aluminum naturally resists corrosion by forming a protective oxide layer within seconds of air exposure. This self-protecting feature eliminates the need for coatings in most environments.

The material machines beautifully. Aluminum cuts quickly with minimal tool wear, though high-silicon content can be slightly abrasive to cutting tools.

Thermal and electrical conductivity are exceptional—making aluminum ideal for heat sinks and electrical components. The material also stays tough at cryogenic temperatures, never becoming brittle in cold conditions.

The main weakness is high-temperature performance. Aluminum loses strength rapidly above 200°C, making it unsuitable for engine hot sections or other high-heat applications.

Nickel superalloys maintain exceptional strength at temperatures where other metals would melt or deform, with some grades performing reliably at 1000°C. Common alloys like Inconel 718 deliver 700 MPa tensile strength at room temperature and still retain over 100 MPa at 700°C.

These alloys resist creep—the tendency to deform slowly under sustained loads at high temperature. Their stable austenitic crystal structure prevents the grain boundary sliding that causes failure in other materials.

Oxidation and corrosion resistance are outstanding. Chromium and aluminum in the alloy form protective oxide scales that shield the base metal from hot gases and combustion products.

The density of nickel alloys (8.1-8.8 g/cc) is comparable to steel, so they’re heavy. But when you need strength at extreme temperatures, nothing else comes close.

Nickel alloys are notoriously difficult to machine. They work-harden instantly during cutting and destroy tools rapidly, which is why investment casting to near-net shape is so crucial.

The material maintains excellent fatigue resistance even after thousands of thermal cycles, making it ideal for parts that repeatedly heat and cool.

Cobalt alloys excel at retaining hardness and wear resistance at high temperatures, with some grades maintaining useful properties up to 900°C. Stellite alloys combine cobalt with chromium and carbides to create surfaces that resist abrasion even when red-hot.

These materials handle thermal fatigue better than any other superalloy. They can withstand rapid temperature changes without cracking—a property that makes them invaluable for turbine components.

Corrosion and oxidation resistance often exceed that of nickel alloys, especially in environments with sulfur compounds. The protective chromium-oxide layer remains stable even under thermal cycling.

Cobalt alloys typically have a density of 8.4-9.0 g/cc, similar to nickel superalloys. Despite being slightly less temperature-capable than top nickel alloys, they offer superior thermal shock resistance.

The extreme hardness that provides wear resistance also makes machining nearly impossible. Most cobalt parts are cast to final shape or finished by grinding and electrical discharge machining (EDM).

Biocompatibility is another key property. Cobalt-chrome-molybdenum alloys are safe for long-term implantation in the human body, resisting corrosion from bodily fluids.

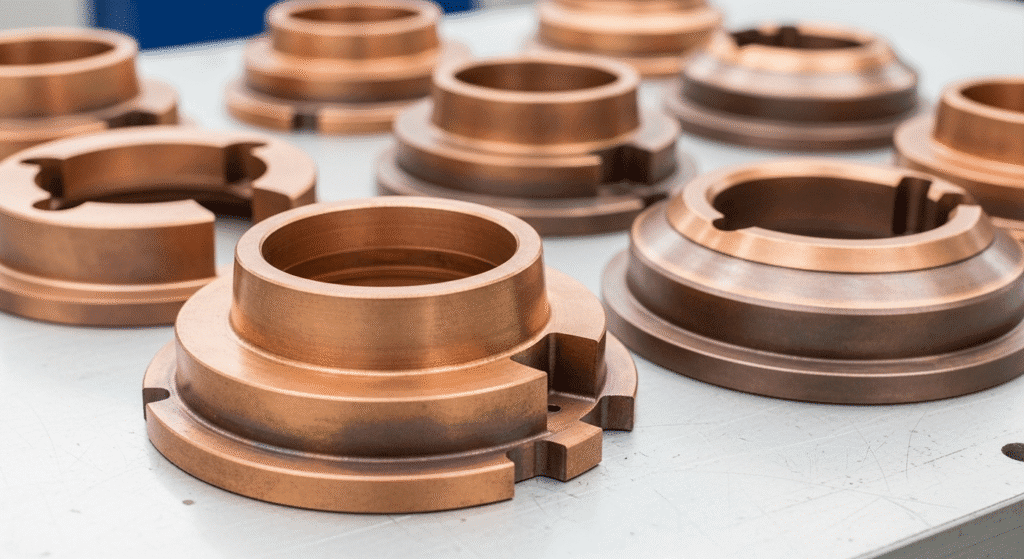

Copper alloys provide excellent corrosion resistance combined with natural antimicrobial properties and high thermal/electrical conductivity. Bronze and brass castings achieve tensile strengths from 200-300 MPa for standard grades to over 1000 MPa for specialty alloys like beryllium-copper.

These materials excel in marine environments. Silicon bronze and aluminum bronze form protective films that prevent degradation in seawater, lasting decades without maintenance.

Low friction and wear resistance make bronze ideal for bearing applications. It runs smoothly against steel surfaces with minimal galling or seizure.

Copper alloys machine exceptionally well, particularly free-cutting brass and leaded bronze. They produce small chips and allow fast cutting speeds with long tool life.

The melting point range of 900-1050°C makes casting straightforward, though these alloys have significant solidification shrinkage (about 6%) that requires careful mold design.

Ductility and toughness are excellent. Copper alloys bend before breaking and maintain toughness even at cryogenic temperatures, unlike steels that become brittle.

Titanium alloys deliver steel-like strength at half the weight, with Ti-6Al-4V achieving 900 MPa tensile strength at a density of just 4.5 g/cc. This exceptional strength-to-weight ratio makes titanium irreplaceable in aerospace applications.

Corrosion resistance rivals that of platinum in many environments. Titanium forms an incredibly stable oxide film that makes it nearly inert in seawater, chlorides, and bodily fluids.

The material maintains good properties up to 400-500°C, though it oxidizes rapidly above this temperature. Special alloys can push the useful range slightly higher.

Titanium has a low elastic modulus (110 GPa), about half that of steel. This flexibility helps absorb impacts but means more deflection under load.

The high melting point of 1668°C and extreme reactivity of molten titanium make casting challenging. It requires vacuum furnaces and special zirconia-based ceramic shells to prevent contamination.

Biocompatibility is perfect—titanium causes no adverse reactions in the human body and actually allows bone to grow directly onto its surface, making it ideal for permanent implants.

| Material Type | Relative Cost (Material) | Corrosion Resistance | Typical Strength[^1] | Machinability (Ease) | Density (g/cc) |

|---|---|---|---|---|---|

| Carbon/Low-Alloy Steel | Low | Low – prone to rust without coating | Medium – high (heat-treatable) | Medium – readily machined and welded | ~7.8 (Heavy) |

| Stainless Steel | High (due to Ni/Cr) | Excellent – resists corrosion and oxidation | Medium – good strength, some grades high | Low – tougher to machine than plain steel | ~7.7–8.0 (Heavy) |

| Aluminum Alloys | Medium | Medium/Good – forms protective oxide | Low – moderate (lower absolute strength) | High – very easy to machine | ~2.7 (Light) |

| Nickel-Based Alloys | Very High – expensive elements | High – outstanding in heat/corrosion | High at high temp (med. at RT) | Low – very difficult to machine | ~8.1–8.8 (Heavy) |

| Cobalt-Based Alloys | Very High – most expensive superalloys | High – superb corrosion and wear resistance | Medium – very good up to ~800 °C | Low – extremely hard; cast to net shape | ~8.4–8.8 (Heavy) |

| Copper-Based Alloys | Medium – copper is moderate cost | High – excellent in marine/normal env. | Low – moderate (bronze < steel; Be-Cu high) | High – easy (esp. brass/lead bronze) | ~7.5–8.9 (Heavy) |

| Titanium Alloys | Very High – costly material & process | High – nearly inert, biomedical-grade | High – steel-like strength at 40% weight | Low – machining and casting are difficult | ~4.5 (Light) |