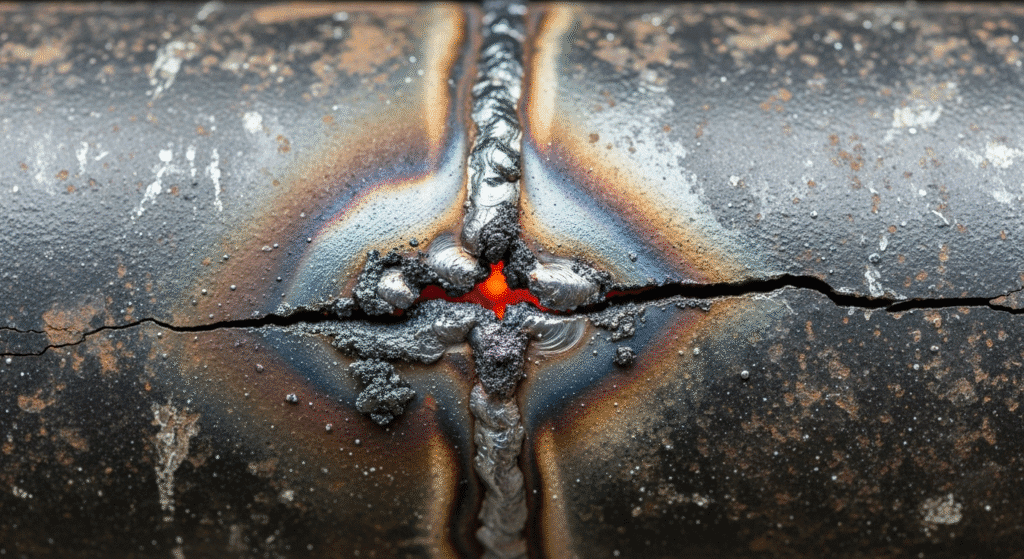

Cast iron welding fails most often because welders treat it like regular steel—but cast iron demands completely different techniques, temperatures, and preparation. These six critical mistakes can turn a simple repair into a cracked, unusable mess that’s harder to fix than the original problem.

Dirty cast iron is impossible to weld properly because oil, grease, and carbon deposits create porosity and weak bonds in your welds. Cast iron acts like a sponge, absorbing oil and contaminants deep into its porous structure over years of use.

You need to grind the weld area down to bright, clean metal and then degrease it thoroughly with acetone or brake cleaner. Many welders just wipe the surface and wonder why their welds crack immediately.

The contamination goes deeper than you can see—sometimes requiring you to grind away a quarter-inch of material to reach clean metal.

Drilling stop-holes at both ends of a crack prevents it from spreading during welding—skip this step and the crack will run ahead of your weld like a zipper opening. The holes should be at least 1/8 inch in diameter and drilled slightly beyond the visible crack ends.

You also need to V-groove the crack at a 60-90 degree angle to ensure full penetration. Trying to weld over a hairline crack without opening it up guarantees the weld won’t bond properly at the root.

High heat input causes cast iron to crack because it can’t handle rapid temperature changes—keep your amperage as low as possible while still achieving fusion. Cast iron expands and contracts differently than your filler metal, and excessive heat magnifies this problem.

Short welds of 1-2 inches at a time, allowing cooling between passes, prevents heat buildup.

Continuous welding creates a heat-affected zone that becomes brittle and cracks as it cools.

Peening each weld bead while it’s still hot (but not molten) relieves stress and prevents cracking—use a ball-peen hammer with light, rapid taps. This technique stretches the weld metal slightly, counteracting the shrinkage forces that cause cracks.

You must also clean between passes to remove slag and impurities that weaken subsequent layers. Running multiple passes without cleaning creates inclusions that act like built-in failure points.

Nickel-based rods (ENi-CI or ENiFe-CI) are the gold standard for cast iron because they’re soft, machinable, and expand similarly to the base metal. Using standard steel rods creates a hard, brittle weld that cracks under the slightest stress.

The wrong filler metal won’t bond properly with cast iron’s high carbon content. Steel rods might look like they’re working initially, but the weld will fail within days or weeks.

Skipping the peening process almost guarantees your cast iron weld will crack because the metal has no way to relieve its internal stress. As molten weld metal cools and contracts, it pulls on the surrounding cast iron with tremendous force.

Proper peening requires hitting the weld while it’s cooling but still above 400°F—too hot and you’ll deform it, too cold and it won’t relieve stress. Use rapid, light strikes along the entire weld length, not heavy blows that could crack the base metal.

Switching between preheated and cold welding techniques on the same part creates uneven stress patterns that lead to failure. If you start with a preheated method at 500°F, maintain that temperature throughout the entire repair.

Mixed temperatures cause different expansion rates across the part, creating stress concentrations at the boundaries.

Preheating cast iron to 400-600°F before welding reduces the temperature differential and prevents thermal shock cracking. Without preheating, the cold cast iron acts like an ice cube hitting hot water—it cracks instantly from the sudden temperature change.

Heating only the weld area while leaving the rest of the part cold creates a stress gradient that causes distortion and cracking. The entire part needs gradual, uniform temperature changes.

Place the part in sand or vermiculite to slow the cooling rate after welding. Rapid cooling in open air creates the same thermal shock you tried to avoid with preheating.

Some welders quench cast iron thinking it needs to be hardened—this is the fastest way to destroy your work completely.

Post-weld heat treatment at 900-1200°F for one hour per inch of thickness removes residual stress and prevents delayed cracking. Without this step, your seemingly successful weld might crack days or weeks later when the part goes into service.

The slow cooling from stress relief temperature—no faster than 50°F per hour—allows the metallurgical structure to stabilize. Wrap the part in ceramic blankets or bury it in sand to control the cooling rate.

Yes, but you need special nickel-based MIG wire and must keep heat input extremely low. Standard steel MIG wire will create brittle welds that crack, so invest in proper NiFe or NiCl wire despite the higher cost.

You’re likely welding too fast or with too much heat, causing thermal stress. Reduce your amperage, weld in short 1-inch segments, peen each bead while hot, and ensure proper preheating to at least 400°F.

Hot welding preheats the entire part to 500-1200°F and maintains this temperature throughout welding. Cold welding uses no preheat but requires specialized nickel rods, minimal heat input, and short weld segments to minimize stress.

Cool cast iron as slowly as possible—ideally over 24 hours for thick sections. Bury the part in sand or vermiculite immediately after welding, and don’t disturb it until it reaches room temperature naturally.