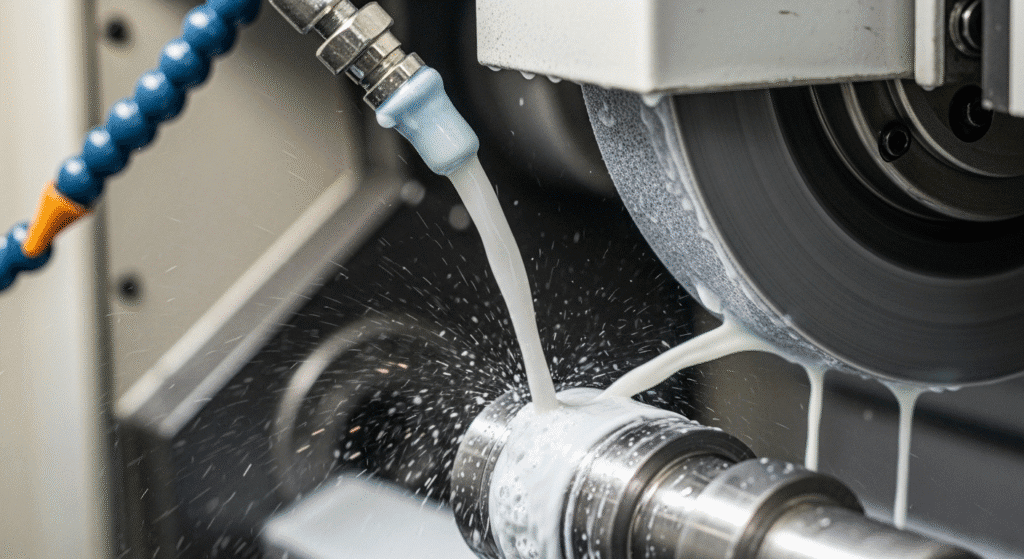

Grinding fluids make the difference between a smooth, precise finish and a warped, burnt mess. These specialized liquids cool your workpiece, flush away metal chips, and prevent your grinding wheel from clogging up—all while protecting against rust.

Choosing the wrong fluid is like using water instead of oil in your car engine. You’ll damage equipment, ruin parts, and waste money. The right fluid depends on what you’re grinding, how fast you’re cutting, and what finish you need.

There are four main types, and each excels at different jobs. Synthetics give you the best cooling and visibility. Semi-synthetics balance cooling with lubrication. Oil-based fluids create mirror finishes on precision parts. Water-soluble oils provide maximum rust protection.

Synthetic grinding fluids are completely water-based solutions without any petroleum oil. They’re like the sports drinks of the grinding world—designed from scratch to deliver specific performance benefits.

These fluids excel at cooling because water transfers heat better than oil. When you’re grinding hard materials or running high-speed operations, synthetics keep temperatures down and prevent warping.

The biggest advantage? They’re crystal clear, so you can see exactly what you’re doing. This transparency makes precision work much easier and safer.

Synthetics also resist bacterial growth better than other types. You won’t deal with that awful “Monday morning smell” that plagues some machine shops. They typically last 6-12 months without needing replacement.

The downside is rust protection. Without oil, synthetics rely on chemical additives to prevent corrosion. You’ll need to monitor concentration levels regularly to maintain protection.

Semi-synthetic fluids combine 5-30% oil with water and synthetic additives. Think of them as the hybrid cars of grinding fluids—offering benefits from both worlds.

These fluids provide better lubrication than full synthetics while maintaining good cooling properties. The small amount of oil creates a protective film on metal surfaces, reducing friction and improving surface finish.

Semi-synthetics work well for most general grinding operations. They’re particularly effective on ferrous metals like steel and cast iron, where you need both cooling and lubrication.

The milky appearance gives you some visibility while still indicating the fluid is working. If it turns completely clear, you know the oil content has dropped too low.

Cost-wise, semi-synthetics hit the sweet spot. They’re more affordable than full synthetics but last longer than straight oils.

Oil-based fluids contain no water—they’re 100% petroleum or mineral oil with additives. These are the traditional choice for precision grinding where surface finish matters most.

The superior lubrication from straight oils produces mirror-like finishes on hardened steel. When you’re grinding tool steel or creating precision components, oil-based fluids prevent microscopic welding between the wheel and workpiece.

These fluids excel in low-speed, heavy-duty grinding operations. The thick oil film handles extreme pressure better than water-based alternatives.

Fire hazard is the main concern. Oil-based fluids require proper ventilation and fire suppression systems. Many shops have switched away from them for safety reasons.

Disposal costs are another factor. Used oil requires special handling and can’t go down regular drains. Environmental regulations make oil-based fluids the most expensive option long-term.

Water-soluble oils contain 40-85% oil that mixes with water to form a milky emulsion. Picture salad dressing—the oil and water blend temporarily when mixed properly.

These fluids offer excellent rust protection from the high oil content. Parts can sit in the machine for days without developing surface rust.

The water component provides cooling while the oil lubricates. This balance makes soluble oils versatile enough for everything from rough grinding to finishing operations.

Mixing ratios typically range from 1:10 to 1:20 (oil to water). Higher oil concentrations improve lubrication but reduce cooling efficiency.

The main challenge is maintaining the emulsion. Hard water can cause the oil and water to separate. You’ll need to check and adjust the mixture weekly.

Synthetic fluids typically last 6-12 months, semi-synthetics 3-6 months, and soluble oils 1-3 months. Check pH levels weekly and change when they drop below 8.5 or when you notice strong odors.

Never mix different fluid types. This causes separation, reduces performance, and can damage your grinding equipment. Always clean the system thoroughly before switching fluid types.

Start with manufacturer recommendations, typically 5-10% for general grinding. Increase concentration for tougher materials or when rust protection is critical. Use a refractometer to maintain consistent levels.