If you’ve ever sourced metal parts, reviewed supplier quotes, or specified components for a project, you’ve probably encountered the term “foundry.” But here’s the problem: most manufacturing professionals work with foundries without fully understanding what happens inside them.

This knowledge gap creates real headaches. You might struggle to communicate specifications to your casting supplier. You could miss cost-saving opportunities by choosing the wrong casting method. Or you might not even realize that casting is the best option for your part.

A foundry is a manufacturing facility that produces metal parts by melting metal and pouring it into molds. Think of it as a factory specifically designed to transform raw metal into shaped components through the casting process.

The terms “foundry” and “casting” get thrown around interchangeably, but they mean different things.

| Term | Definition |

|---|---|

| Foundry | The physical facility where casting happens |

| Casting | The process of pouring molten metal into a mold |

| Metalcasting | The broader industry term for the casting process |

| Cast Part | The finished metal component produced |

Here’s a simple way to remember it: a foundry is where you go, and casting is what they do there.

Foundries specialize based on the metals they work with and the casting methods they use. Understanding these differences helps you find the right supplier for your specific needs.

Foundries split into two main categories based on metal type: ferrous (iron-based) and non-ferrous (everything else).

| Factor | Ferrous Foundries | Non-Ferrous Foundries |

|---|---|---|

| Materials | Iron, steel, stainless steel | Aluminum, copper, bronze, zinc, titanium |

| Strength | Higher tensile strength | Lower, but excellent strength-to-weight ratio |

| Corrosion Resistance | Lower (rusts without treatment) | Higher (naturally resistant) |

| Weight | Heavier | Lighter |

| Typical Products | Engine blocks, pipes, heavy machinery | Aerospace parts, marine components, electrical housings |

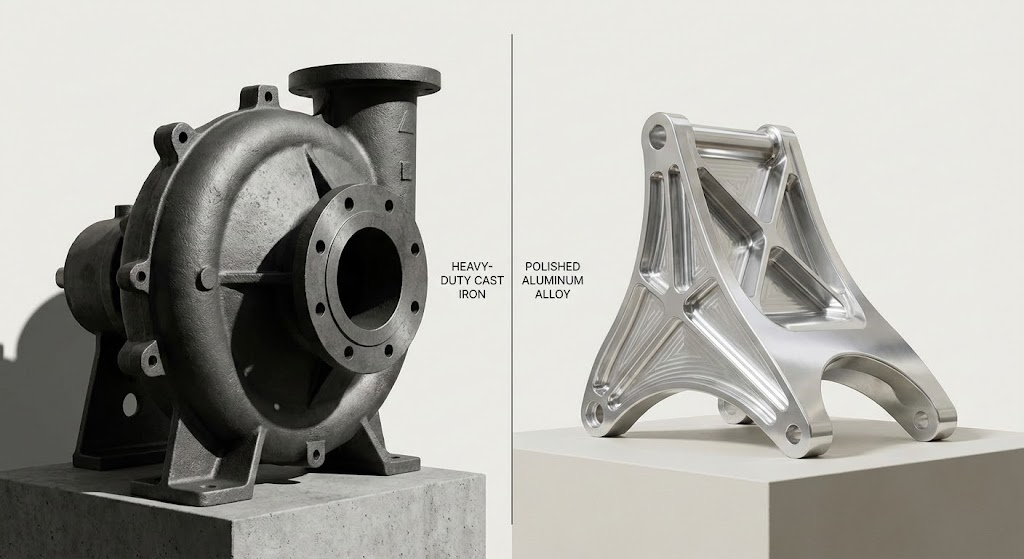

Ferrous foundries dominate heavy industrial applications. If you need a massive pump housing or a structural component that can handle extreme loads, ferrous is your answer.

Non-ferrous foundries excel when weight matters. Aerospace, automotive, and marine industries rely heavily on aluminum and bronze castings because they’re lighter and resist corrosion better than iron.

The casting method your foundry uses affects everything: cost, quality, lead time, and what’s even possible to produce.

| Method | Best For | Tolerance | Tooling Cost | Ideal Volume |

|---|---|---|---|---|

| Sand Casting | Large parts, prototypes | ±3mm | Low | Low to medium |

| Die Casting | High-volume production | ±0.13mm | High | High (10,000+) |

| Investment Casting | Complex, precise parts | ±0.05mm | Medium | Low to medium |

| Permanent Mold | Consistent mid-volume runs | ±0.5mm | Medium | Medium |

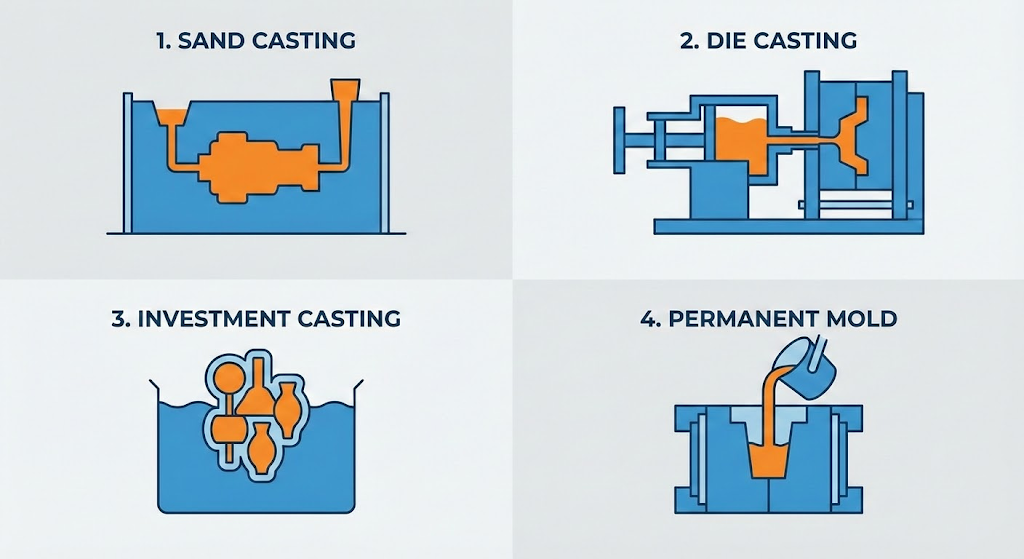

Sand casting is the most common method globally. It’s versatile and cost-effective, with lead times as short as 1-2 weeks. The trade-off? Rougher surface finish and looser tolerances.

Die casting uses high pressure to inject molten metal into steel molds. Tooling costs $10,000 to $100,000+, but per-part costs drop dramatically at high volumes. It works best with non-ferrous metals like aluminum and zinc.

Investment casting (also called lost-wax casting) produces incredibly precise parts with excellent surface finish. It’s perfect when you need tight tolerances on complex geometries.

Permanent mold casting offers a middle ground. The reusable metal molds last longer than sand but cost less than die casting tooling.

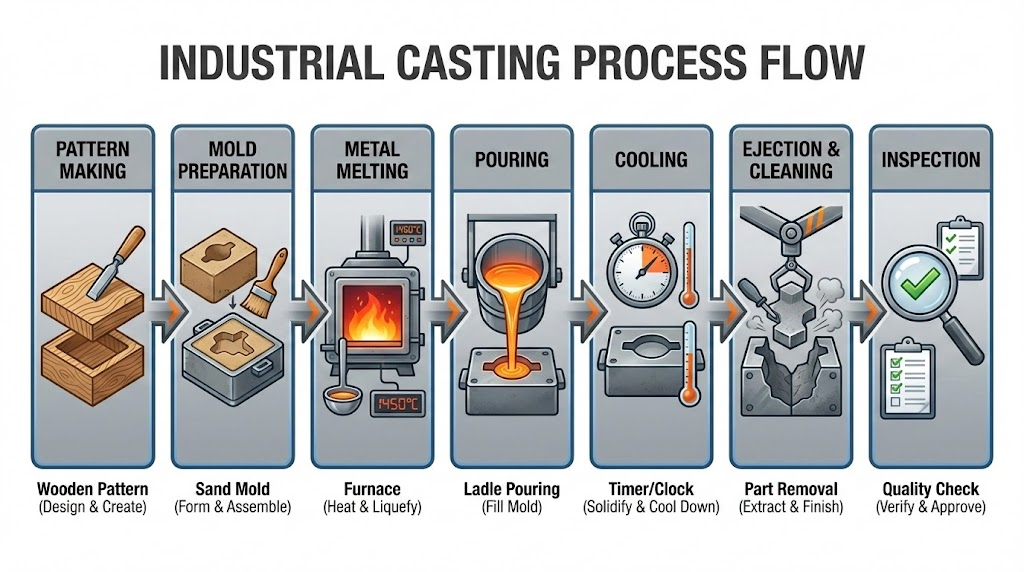

Metal casting follows a predictable sequence regardless of the specific method. Understanding these steps helps you communicate better with your foundry and troubleshoot issues.

Selecting the right casting method comes down to five key factors. Get these right, and you’ll save time and money.

| Your Priority | Best Method | Why |

|---|---|---|

| Complex geometry | Investment casting | Creates intricate shapes impossible with other methods |

| High volume (10,000+ parts) | Die casting | Lowest per-part cost at scale |

| Large parts (100+ lbs) | Sand casting | No size limitations, lowest tooling cost |

| Tight tolerances | Die or investment casting | Both achieve ±0.005 in or better |

| Fast prototyping | Sand casting | 1-2 week lead time, minimal tooling |

| Budget constraints | Sand casting | Lowest upfront investment |

My advice: don’t default to the cheapest option. A slightly more expensive casting method might eliminate secondary machining operations and actually reduce total cost.

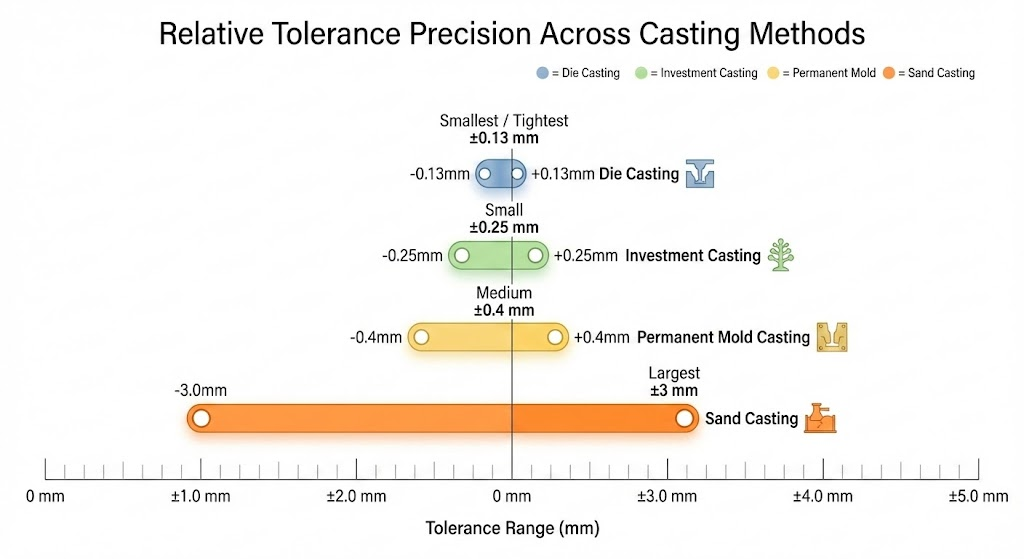

Tolerance specifications determine whether your casting works as intended. Casting tolerances follow ISO 8062 standards, but each method achieves different precision levels.

| Method | Linear Tolerance | Surface Finish (RMS) |

|---|---|---|

| Die Casting | ±0.005 in (±0.13mm) | 20-120 |

| Investment Casting | ±0.002 to ±0.010 in | 60-125 |

| Permanent Mold | ±0.015 in (±0.4mm) | 200-400 |

| Sand Casting | ±0.125 in (±3mm) | 300-560 |

Die casting achieves the smoothest finish right out of the mold. Sand casting produces the roughest surfaces but handles the largest parts.

Here’s what most engineers miss: the industry target for defect rates is under 2%, but actual rates range from 3% to 25% depending on the foundry. Always ask suppliers about their defect rates and inspection methods.

Now you understand what foundries actually do, how different casting methods compare, and what factors drive the right selection. Use this knowledge to ask better questions when sourcing castings, push back on suppliers when specifications don’t match capabilities, and choose the manufacturing method that truly fits your application.

When you’re specifying your next cast part, start with volume and tolerance requirements. Those two factors alone will narrow your options to one or two casting methods. From there, material selection and cost analysis will point you to the right foundry type.