The car you drove today, the bridge you crossed, the knife in your kitchen drawer – they all share something in common. Carbon steel. This single material shapes more of our daily lives than any other metal, commanding over $1 trillion in global market value. Yet most people have no idea what makes it different from other types of steel.

Understanding carbon steel matters if you’re designing a product, selecting materials for a project, or simply curious about how things are made. This guide breaks down everything you need to know: what carbon steel actually is, the three main types, how it compares to stainless steel, and when it’s the right choice for your application.

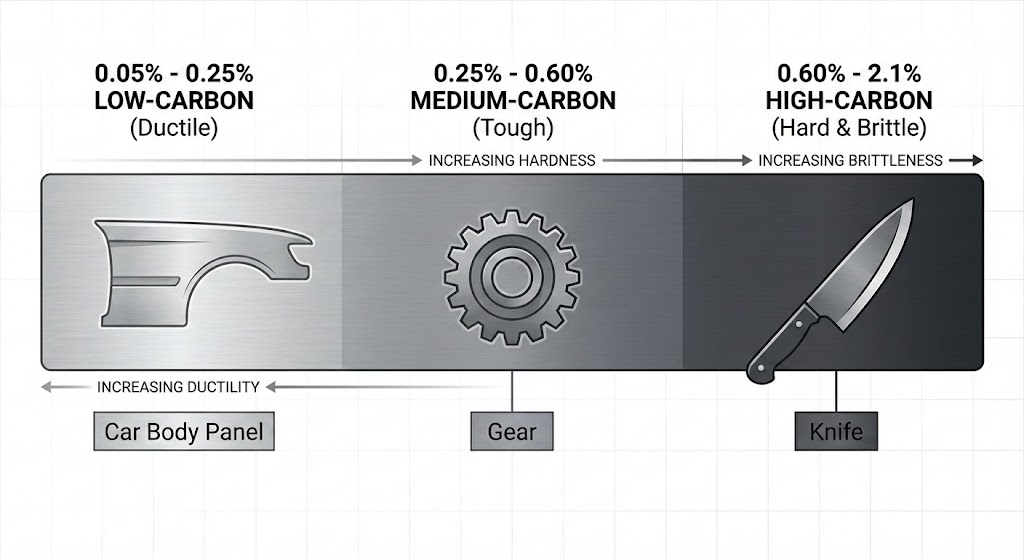

Carbon steel is iron mixed with a small amount of carbon – specifically between 0.05% and 2.1% by weight. That’s it. No fancy additives, no exotic elements. Just iron and carbon working together.

You might hear it called “plain carbon steel” because manufacturers don’t deliberately add other alloying elements. The steel may contain trace amounts of manganese, silicon, or copper from the production process, but carbon remains the star of the show.

This simplicity makes carbon steel the most common type of steel in the world. Low-carbon steel alone accounts for 90.2% of the entire carbon steel market. When someone mentions “steel” without specifying a type, they’re almost certainly talking about carbon steel.

Here’s something that surprises most beginners: that tiny percentage of carbon – sometimes less than what’s in your morning coffee – dramatically transforms the metal’s behavior.

Think of it like salt in cooking. A pinch changes everything. Too little and the dish falls flat. Too much and it becomes inedible. Carbon works the same way in steel.

More carbon means harder and stronger steel. But there’s a trade-off. As hardness increases, the steel becomes more brittle and harder to weld. This strength-versus-workability balance is the key to understanding why different types of carbon steel exist.

For most applications, I recommend starting with low-carbon steel. The 90.2% market share isn’t an accident – it reflects the reality that workability and weldability matter more than maximum hardness for typical projects.

Low-carbon steel contains 0.05% to 0.30% carbon, making it the softest and most workable option. It bends without cracking. It welds cleanly. Machines cut through it without excessive tool wear.

Construction crews use it for structural beams and columns. Auto manufacturers stamp it into body panels. Plumbers connect buildings with low-carbon pipes. Even the food cans in your pantry started as low-carbon steel sheets.

The lower price point seals the deal for most applications. Unless you specifically need hardness or edge retention, low-carbon steel handles the job at a fraction of the cost.

Medium-carbon steel sits in the middle ground, offering a balance between strength and workability. It contains 0.30% to 0.60% carbon and responds well to heat treatment through quenching and tempering.

Manufacturers choose it for parts that need more strength but still require shaping: gears, crankshafts, axles, and machinery shafts. These components face repeated stress and wear, demanding more than low-carbon can provide.

The heat treatment capability sets medium-carbon apart. You can harden specific areas while leaving others softer – useful when a part needs a hard wearing surface but a tough, shock-resistant core.

High-carbon steel pushes carbon content from 0.60% up to around 1.5%. On the Rockwell Hardness Scale, it can reach 60-65 HRC – hard enough to scratch glass.

This hardness makes it ideal for cutting tools, springs, knives, and wire ropes. A well-made kitchen knife holds its edge because high-carbon steel resists deformation. Springs snap back reliably because the material won’t permanently bend under repeated stress.

However, high-carbon steel comes with serious limitations. It cracks more easily, resists welding, and demands careful handling during manufacturing. Reserve it for applications where maximum hardness justifies the extra difficulty. For more detail on the differences, see our guide on low vs medium vs high carbon steel.

| Your Priority | Choose This Type | Why It Works |

|---|---|---|

| Easy welding and forming | Low-carbon | Most ductile, simplest to work with |

| Balanced strength and flexibility | Medium-carbon | Heat-treatable for custom properties |

| Maximum hardness and edge retention | High-carbon | Highest strength, holds sharp edges |

Skip carbon steel for corrosive or high-moisture environments unless you’re committed to protective coatings. Avoid it for applications above 427C where thermal degradation becomes a concern. Consider alternatives when weight is critical – aerospace and portable equipment often need lighter materials. Medical and food applications typically require stainless steel’s superior corrosion resistance.

Carbon steel offers an unbeatable combination of strength, workability, and cost. Low-carbon works for most general applications. Medium-carbon handles parts needing extra strength. High-carbon delivers maximum hardness for cutting tools and springs.

Ready to discuss carbon steel for your project? Contact our team to explore material options and get a quote on your custom metal parts.