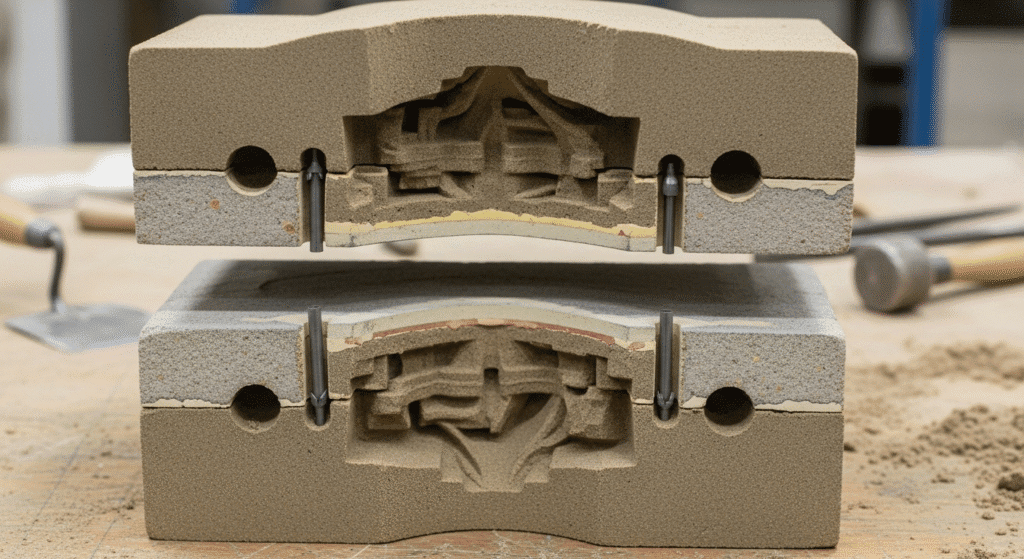

Cope and drag are simply the top and bottom halves of a casting mold. The drag sits at the bottom and the cope sits on top, and together they form a complete mold cavity ready to receive molten metal.

The flask is the frame—typically made of metal or wood—that holds these two halves together and contains all the sand. Inside the flask, the drag and cope meet along a line called the parting line. This parting line is critical because it’s where the pattern gets divided. The upper half of your pattern goes into the cope, and the lower half goes into the drag. When you separate the two halves, you can remove the pattern and create your mold cavity.

Why use two halves instead of one mold? The answer is practical. Complex parts often have undercuts, internal passages, or features that would be impossible to extract from a single-piece mold. By dividing the mold in half, you can remove your pattern cleanly without tearing up the sand.

The process starts by placing the drag—the bottom half—upside down on a molding board. Your pattern, which is essentially a model of the part you want to cast, gets positioned inside the drag. The drag is packed with green sand, which is sand mixed with a binder (usually clay) and water to hold its shape. Workers use a ramming process, often with vibrations, to pack the sand tightly around the pattern.

Once the drag is fully packed and the sand is firm, the cope—the top half—gets placed on top of the drag. At this point, alignment pins (which we’ll discuss more in a moment) keep the two halves from shifting. More green sand fills the cope around the upper half of the pattern until everything is packed tight.

Here’s where the real skill comes in. The cope and drag get separated, and now you need to extract your pattern without destroying the sand cavity. The foundry worker uses a draw spike—a rod that gets driven into the pattern—and taps it gently in all directions to loosen it.

The pattern comes out carefully, leaving behind a perfect cavity in the sand. The worker might need to pay attention to draft angles—slight tapers built into the pattern that make extraction easier. Patterns typically have draft angles of at least 1 degree to prevent the sand from sticking and breaking.

After removing the pattern, small passages need to be cut into the sand to guide the molten metal into the cavity. The sprue is the main vertical passage where metal enters. The gate connects the sprue to the mold cavity. Foundry workers cut these passages by hand, using specialized tools to carve channels in the sand.

The cope and drag get reassembled and clamped together. The alignment pins ensure the mold halves line up perfectly. Molten metal pours down the sprue, through the gate, and into the mold cavity. The metal fills the space where your pattern used to be, taking on its exact shape.

As the metal cools and solidifies, it shrinks slightly and forms the rough casting. Once cool enough, the flask is opened by separating the cope and drag again, and the sand is brushed away to reveal the casting underneath.

These are dowels or rods that fit into corresponding holes in both the cope and the drag. When you close the mold, the pins slide into place and lock the two halves together in perfect alignment.

The parting line is where the cope meets the drag, and it determines how your part gets divided. An ideal parting line goes through the thickest part of the casting, avoiding corners and complex geometry.

Match-plate casting uses a single two-sided pattern mounted on a metal plate. The cope and drag halves are molded simultaneously on either side of the plate. This works well for medium-sized parts in moderate production volumes, but the pattern gets too heavy and awkward for very large parts.

Cope and drag wins when parts get large or production volume stays low. Match-plate wins when you need consistent, high-volume output of moderately-sized castings.

Choose cope and drag when you have large, complex castings or custom parts where expensive tooling doesn’t make economic sense. It’s your best option when you need design flexibility and can accept the manual nature of the process.

If you’re casting small, simple parts in massive quantities, faster automated methods will serve you better. If your parts are tiny and require tight tolerances, other methods might be more suitable. But for large, intricate castings where quality and cost-effectiveness matter, cope and drag remains the logical choice.

Cope and drag casting represents a fundamental approach to metal manufacturing that’s been perfected over centuries. These two mold halves—the cope on top and the drag on bottom—make it possible to cast complex shapes that would be impossible to produce any other way.

The system excels because it balances cost-effectiveness, design flexibility, and proven reliability. You won’t find a cheaper way to create a large, complex metal casting, and the established procedures mean you can trust the results. That’s why foundries across the world still use this method for everything from car engines to industrial equipment.