GGG stands for “Kugelgraphitguss” (German for spheroidal graphite cast iron), and 50 refers to the minimum tensile strength of 50 kg/mm²(500 MPa).

Originally designated under the German DIN 1693 standard, this material gets its name from its minimum tensile strength of 50 kg/mm². It’s now commonly known as EN-GJS-500-7 under European standards, where the “500-7” indicates 500 MPa minimum tensile strength and 7% minimum elongation.

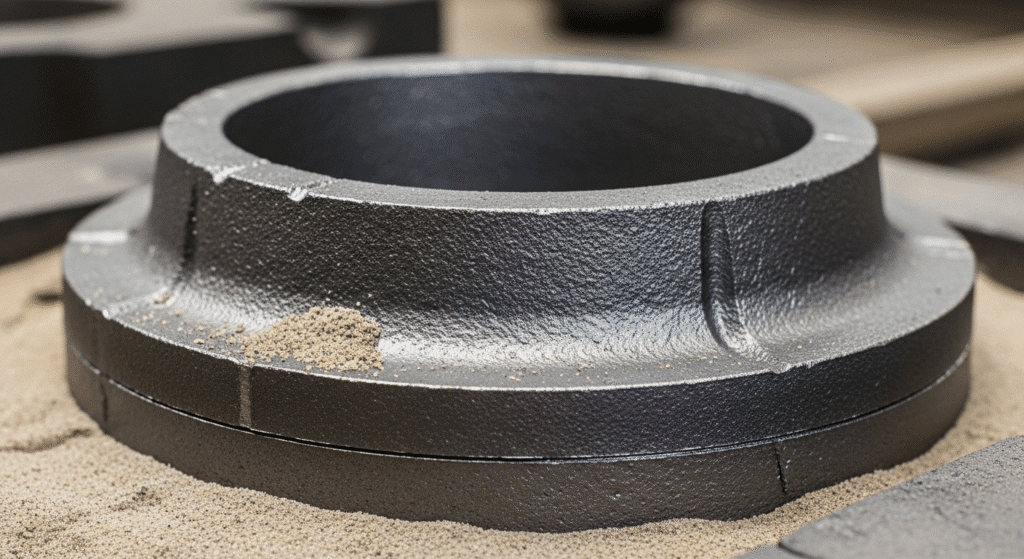

What makes GGG-50 special is its microstructure. Unlike gray cast iron with flake graphite, GGG-50 contains graphite in spherical nodules. This spheroidal graphite, combined with a ferritic-pearlitic matrix, gives the material steel-like mechanical properties while maintaining excellent castability and vibration damping characteristics typical of cast iron.

| Element | Typical Content (wt%) | Purpose |

|---|---|---|

| Carbon (C) | 3.3 – 3.7 | Forms graphite nodules; provides castability |

| Silicon (Si) | 2.4 – 3.0 | Promotes graphite formation; strengthens ferrite |

| Manganese (Mn) | 0.10 – 0.30 | Controls pearlite formation |

| Sulfur (S) | 0.005 – 0.02 | Kept low to prevent embrittlement |

| Phosphorus (P) | 0.015 – 0.08 | Minimized to maintain ductility |

| Magnesium (Mg) | 0.04 – 0.07 | Critical for spheroidal graphite formation |

| Iron (Fe) | Balance | Base element |

| Property | Typical Value | Notes |

|---|---|---|

| Tensile Strength (Rm) | ≥ 500 MPa | Minimum requirement |

| Yield Strength (Rp0.2) | ≥ 320 MPa | 0.2% offset yield point |

| Elongation (A5) | ≥ 7% | Measured on standard test bars |

| Hardness | 170 – 230 HB | Higher pearlite increases hardness |

| Elastic Modulus | ~169 GPa | About 20% lower than steel |

| Impact Energy (Charpy) | 3 – 4 J | At room temperature |

| Compressive Strength | ~900 MPa | Much higher than tensile |

| Shear Strength | ~450 MPa | Important for gear applications |

| Fatigue Limit | 200 – 250 MPa | Under reversed bending |

GGG-50’s physical properties make it suitable for applications requiring heat dissipation and dimensional stability. The material has a density of approximately 7.1 g/cm³, making it slightly lighter than steel due to its graphite content.

The thermal conductivity is around 35 W/(m·K) at room temperature. While lower than steel, this still provides decent heat dissipation for components like brake drums and engine blocks. The thermal expansion coefficient is 12.0-12.5 × 10⁻⁶/K between 20-400°C, similar to steel, which means thermal compatibility in mixed-material assemblies.

GGG-50 can operate continuously up to about 450°C. Beyond this temperature, the ferrite begins to deform through creep, and the material’s strength drops significantly. The material also provides excellent vibration damping compared to steel, though less than gray cast iron, making it valuable for reducing noise in machinery.

Machinability is one of GGG-50’s strongest advantages. The material machines exceptionally well, with a rating of 60-100% compared to free-machining steel. The graphite nodules act as chip breakers and provide natural lubrication during cutting operations.

Typical cutting speeds with carbide tools range from 150-250 m/min for turning and 100-180 m/min for milling. The material produces short, brittle chips that are easy to manage, and the moderate hardness (170-230 HB) allows for efficient machining with standard tooling.

Weldability, however, requires special attention. GGG-50’s high carbon content (3.3-3.7%) makes conventional welding challenging. Successful welding requires:

Without these precautions, the heat-affected zone can form hard, brittle carbides leading to cracking. For this reason, brazing or mechanical fastening is often preferred over welding.

GGG-50 responds well to various heat treatments that can modify its properties for specific applications. Normalizing at ~900°C followed by air cooling increases strength to 550-600 MPa by creating a finer pearlitic structure, though elongation may drop to 3-5%.

Annealing at 900°C with slow cooling increases the ferrite content, improving ductility but reducing strength. This treatment shifts properties toward a 450-10 grade (450 MPa tensile, 10% elongation).

Surface hardening through induction or flame hardening can create a hard wear-resistant surface (up to 55 HRC) while maintaining a tough core. This is commonly applied to gear teeth and camshafts. The material can also be nitrided to form a hard surface layer for improved wear resistance.

Austempering can transform GGG-50 into ADI (Austempered Ductile Iron), achieving tensile strengths up to 1200 MPa with 8-10% elongation, though this creates a different material grade altogether.

GGG-50 is recognized internationally under various designations, all referring to essentially the same material with minor specification differences.

| Standard | Grade Designation | Country/Region |

|---|---|---|

| EN 1563 | EN-GJS-500-7 | Europe |

| ISO 1083 | 500-7 | International |

| DIN 1693 | GGG-50 | Germany (historical) |

| ASTM A536 | 70-50-05 | USA |

| JIS G5502 | FCD500-7 | Japan |

| GB/T 1348 | QT500-7 | China |

| BS 2789 | 500/7 | UK (historical) |

| UNI 4544 | GS 500-7 | Italy |

| NF A32-201 | FGS 500-7 | France |

| GOST 7293 | VCh 50 (ВЧ50) | Russia |

GGG-50 has much higher tensile strength (500 MPa vs. 200-300 MPa) and ductility (7% vs. virtually none) than gray cast iron, thanks to its spheroidal graphite structure.

No, GGG-50 requires special nickel-based electrodes, preheating to 250-300°C, and controlled cooling to prevent cracking due to its high carbon content.

Yes, GGG-50 is ferromagnetic like most iron-based materials, making it suitable for applications requiring magnetic properties.

GGG-50 is typically more economical than cast or forged steel for complex shapes, offering lower melting temperatures and better castability while achieving comparable strength.