The main difference between expendable mold casting and permanent mold casting is reusability. Expendable mold casting uses single-use molds that break apart to remove the finished part. Permanent mold casting uses metal molds that produce thousands of parts before replacement.

This fundamental difference affects cost, production speed, part quality, and design flexibility. Manufacturers choose between these methods based on production volume, budget, and part requirements.

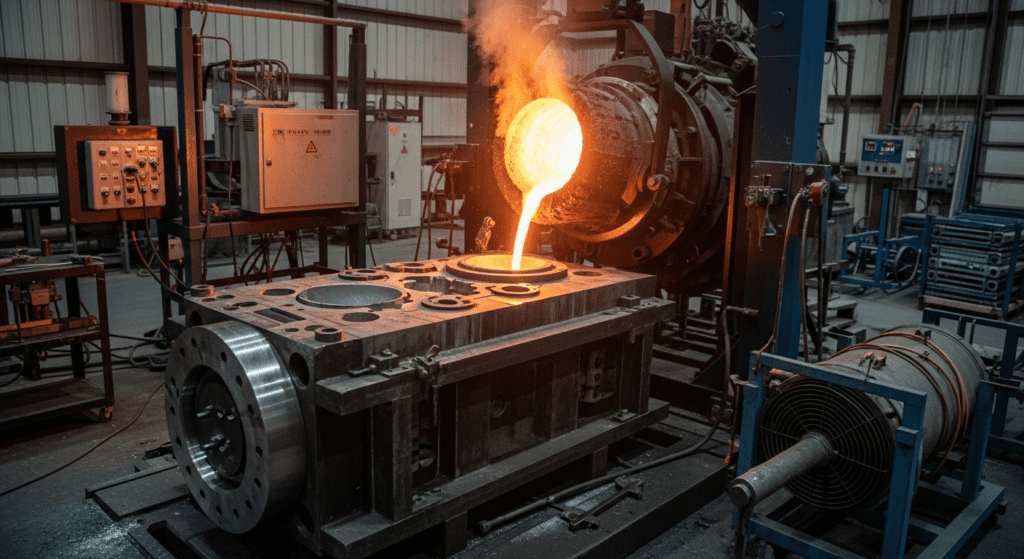

Expendable mold casting creates metal parts using molds that are destroyed after each use. The process involves pouring molten metal into a mold made from sand, plaster, or ceramic materials.

After the metal cools and solidifies, workers break the mold to retrieve the part. This means creating a new mold for every single casting.

The method works well for complex shapes and large parts. It also allows for intricate internal features using cores. However, each part requires significant time and labor to create the mold.

Sand casting uses sand mixed with clay or chemical binders to form the mold. It’s the most common and oldest casting method.

The process handles parts from a few ounces to several tons. Sand molds cost less than other expendable molds but produce rougher surface finishes.

Shell molding creates thin-walled molds using resin-coated sand. Heat hardens the resin, forming a shell around the pattern.

This method produces better surface finishes and tighter tolerances than sand casting. It works best for medium-sized parts in moderate production runs.

Investment casting, also called lost-wax casting, creates precise parts with excellent surface finishes. The process uses wax patterns coated with ceramic slurry.

After the ceramic hardens, heat melts out the wax. This leaves a hollow ceramic mold ready for metal pouring. The method excels at complex geometries and thin walls.

Plaster mold casting uses gypsum plaster mixed with water to create molds. The process works only with non-ferrous metals due to plaster’s low heat resistance.

Parts have smooth surfaces and good dimensional accuracy. However, plaster molds take longer to prepare and have limited material compatibility.

Ceramic mold casting uses fine ceramic powders mixed with binders. The molds withstand higher temperatures than plaster molds.

This allows casting of ferrous and high-temperature alloys. The process produces parts with good surface finish and dimensional control.

Evaporative pattern casting, including lost foam casting, uses foam patterns that vaporize when metal enters the mold. The foam pattern stays in the sand mold during pouring.

This eliminates the need for pattern removal before casting. The method reduces labor and allows complex internal passages without cores.

Permanent mold casting uses reusable metal molds, typically made from steel or iron. The molds last for thousands of casting cycles before needing replacement.

The process relies on gravity, pressure, or vacuum to fill the mold cavity with molten metal. Metal molds conduct heat faster than sand molds, creating different cooling rates and material properties.

This method suits high-volume production of aluminum, zinc, and magnesium parts. The initial mold cost is high, but per-part costs decrease with volume.

Gravity permanent mold casting relies on gravity alone to fill the mold. Molten metal pours into the top of the mold and flows downward.

The simple process requires minimal equipment beyond the mold itself. It produces consistent parts with good mechanical properties and moderate production rates.

Low-pressure casting uses air pressure to push molten metal up into the mold. The metal rises from a sealed furnace below the mold.

This controlled filling reduces turbulence and air entrapment. The method improves casting quality and reduces porosity compared to gravity casting.

Vacuum permanent mold casting removes air from the mold cavity before filling. This creates cleaner metal flow and reduces gas porosity.

The vacuum also helps pull metal into thin sections. Parts have superior mechanical properties and surface finish compared to atmospheric casting methods.

Die casting forces molten metal into the mold under high pressure. Machines apply hundreds to thousands of pounds per square inch.

This pressure fills thin walls and fine details quickly. The rapid cycle times make die casting the fastest permanent mold process for high-volume production.

Centrifugal casting spins the mold during pouring and solidification. Centrifugal force pushes metal against the mold walls.

The process creates hollow cylindrical parts like pipes and rings. Denser material concentrates at the outer surface, while impurities move inward.

Initial tooling costs differ dramatically between methods. Expendable molds cost less upfront but require new molds for each part.

Permanent molds cost thousands to hundreds of thousands of dollars initially. However, they produce many parts without additional mold costs. The break-even point typically occurs between 1,000 and 10,000 parts.

Permanent mold casting produces parts much faster than expendable methods. A permanent mold cycle takes minutes, while expendable molds need hours or days.

The time difference comes from mold preparation. Permanent molds need only coating renewal between cycles. Expendable processes must create entirely new molds.

Expendable mold casting suits prototype and low-volume production. The low tooling cost makes it economical for small quantities.

Permanent mold casting requires high volumes to justify tooling investment. Most applications need at least 1,000 parts annually to be cost-effective.

Permanent mold casting achieves tighter tolerances than most expendable methods. Metal molds maintain consistent dimensions across thousands of parts.

Investment casting is the exception among expendable methods. It matches or exceeds permanent mold tolerances but at higher cost.

Metal molds produce smoother surface finishes than sand molds. Permanent mold parts often need minimal finishing operations.

Among expendable methods, investment and plaster casting create the best surfaces. Sand casting typically requires more extensive finishing work.

Expendable molds excel at complex internal geometries. Cores can create intricate passages that would trap a permanent mold.

Permanent molds must allow part removal without breaking. This limits undercuts, internal features, and re-entrant angles in the design.

Sand casting handles the largest parts, from small components to multi-ton castings. No other process matches its size range.

Permanent mold casting typically limits parts to under 50 pounds. Larger permanent molds become impractical due to cost and handling difficulty.

Permanent mold casting produces thinner walls than sand casting. Metal molds’ rapid cooling supports walls as thin as 3mm.

Investment casting achieves the thinnest walls among all methods. Some parts have walls under 1mm thick. Sand casting rarely goes below 5mm successfully.

Expendable molds work with nearly any castable metal. High-melting alloys like steel and titanium require expendable processes.

Permanent molds suit lower-melting alloys. Aluminum, zinc, and magnesium represent most permanent mold applications. The mold material must withstand repeated thermal cycling.