GGG-50 and GGG-40 are two grades of ductile cast iron that differ primarily in their strength and ductility balance. GGG-50 offers 25% higher tensile strength (500 MPa vs 400 MPa) and better wear resistance, while GGG-40 provides double the elongation (15% vs 7%) and superior impact toughness. This fundamental trade-off—strength versus ductility—determines which grade engineers choose for specific applications.

| Property | GGG-40 (EN-GJS-400-15) | GGG-50 (EN-GJS-500-7) |

|---|---|---|

| Tensile Strength | 400 MPa (minimum) | 500 MPa (minimum) |

| Yield Strength | ~250 MPa | ~320 MPa |

| Elongation | 15% (minimum) | 7% (minimum) |

| Hardness (Brinell) | 130-180 HB | 170-230 HB |

| Impact Resistance | Excellent | Moderate |

| Fatigue Strength | Higher | Lower |

GGG-50’s higher yield strength (320 MPa) means it can handle greater static loads without permanent deformation. It’s roughly 28% stronger than GGG-40 in this regard.

The elongation difference is even more dramatic. GGG-40 can stretch 15% before breaking—about double what GGG-50 can manage. This extra ductility translates directly into better shock absorption and resistance to sudden impacts.

| Element | GGG-40 (typical %) | GGG-50 (typical %) |

|---|---|---|

| Carbon (C) | 3.50-3.60 | 3.60-3.80 |

| Silicon (Si) | 3.00-3.20 | 2.50-2.90 |

| Manganese (Mn) | ~0.5 | ~0.6 |

| Phosphorus (P) | 0.07 max | 0.08 max |

| Sulfur (S) | 0.02 max | 0.025 max |

| Magnesium (Mg) | ~0.04 | 0.03-0.05 |

| Nodulizers (Ce, RE) | ~0.02 | 0.03-0.05 |

The key difference lies in silicon content. GGG-40’s higher silicon (3.00-3.20%) promotes a ferritic matrix structure, which is softer and more ductile. GGG-50’s lower silicon (2.50-2.90%) combined with slightly higher carbon creates more pearlite in the microstructure.

This pearlite-ferrite balance determines everything. GGG-40 is mostly ferritic with some pearlite, giving it flexibility. GGG-50 contains significantly more pearlite, which acts like tiny hard particles throughout the material, increasing strength but reducing ductility.

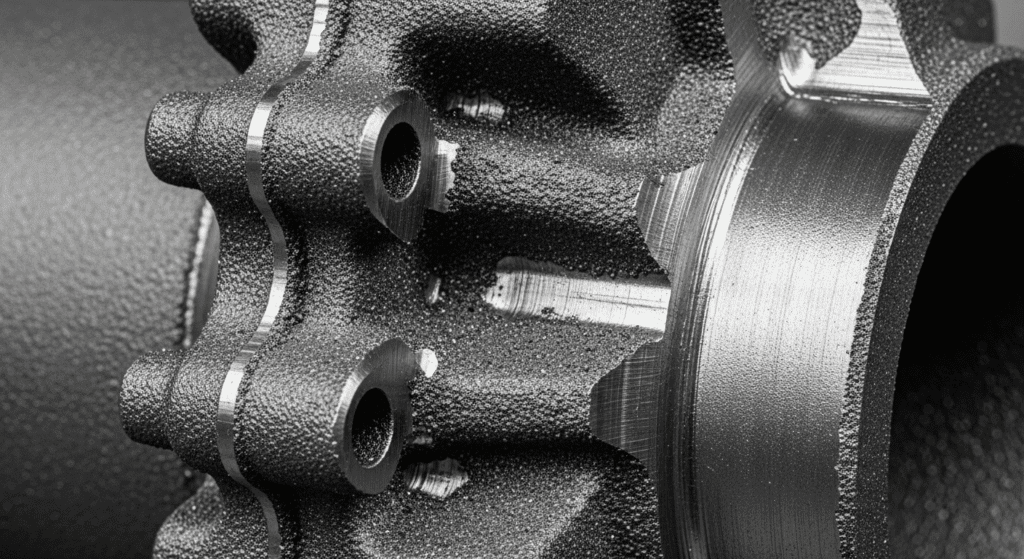

GGG-50 provides superior wear resistance due to its higher hardness (170-230 HB) and pearlitic content. The harder surface resists abrasion better under sliding or rolling contact conditions.

GGG-40 still offers decent wear properties for moderate-duty applications. Its graphite nodules provide natural lubrication, and the material works well for gears or crankshafts where some wear is acceptable. The softer matrix actually helps in applications where parts need to “bed in” or conform slightly during initial operation.

For maximum wear resistance under harsh conditions, GGG-50 is the clear choice. But if wear demands are moderate and other factors like impact resistance matter more, GGG-40 often performs better overall.

GGG-40 significantly outperforms GGG-50 in toughness and impact resistance. Its 15% elongation allows it to absorb shock loads and deform plastically without cracking.

This superior toughness makes GGG-40 ideal for components facing dynamic loads, vibrations, or thermal shock. It can bend considerably before breaking, while GGG-50 tends toward brittle failure when overloaded.

GGG-40 also maintains better toughness at low temperatures. When components might face sub-zero conditions, GGG-40’s ductility provides a crucial safety margin against brittle fracture.

Both grades machine well compared to other cast irons, thanks to their graphite nodules that break chips and provide lubrication during cutting.

GGG-40 machines slightly easier due to its lower hardness (130-180 HB). It cuts similarly to medium-carbon steel, and tools last longer. Drilling and tapping operations run smoothly with standard tooling.

GGG-50 remains easily machinable despite its higher strength. Its hardness (170-230 HB) increases tool wear slightly but doesn’t prevent achieving fine finishes and tight tolerances. Most shops can handle GGG-50 with their standard equipment and practices.

The machinability difference becomes noticeable in high-volume production. If you’re making thousands of parts, GGG-40’s lower tool wear translates to meaningful cost savings. For smaller batches, both materials work equally well from a practical standpoint.

GGG-40 Applications:

GGG-50 Applications:

The choice often comes down to load type. If parts face primarily static loads with minimal impact, GGG-50’s extra strength allows thinner, lighter designs. When components must survive shocks, vibration, or temperature swings, GGG-40’s toughness provides better reliability.

Yes, GGG-40 actually handles dynamic pressure better than GGG-50, with German standards allowing it up to 100 bar versus 63 bar for GGG-50.

GGG-50 provides better wear resistance due to its higher hardness (170-230 HB vs 130-180 HB).

The materials cost similarly, but GGG-40 may reduce machining costs due to lower tool wear in high-volume production.

Both can be welded with proper procedures, but GGG-40 welds more reliably due to its lower carbon equivalent and ferritic structure.