Manufacturing professionals often face critical decisions when selecting the most appropriate metal forming process for their applications. Two prominent techniques—casting and forging—represent fundamentally different approaches to creating metal components, each with distinct advantages and limitations.

This article explores the essential differences between investment casting and forging, examining how these processes affect material properties, geometric capabilities, and overall performance of the finished parts.

Investment casting, also known as precision casting or lost-wax casting, creates components with exceptional dimensional accuracy and intricate details. The process begins with a wax pattern that mirrors the desired final product. This wax form gets coated with multiple layers of ceramic material, creating a robust shell. After the ceramic hardens, the wax melts away—hence the term “lost-wax”—leaving a precise cavity. Manufacturers then pour molten metal into this cavity, allowing it to solidify into the exact shape of the original pattern.

Forging shapes metal while it remains solid, typically heated to enhance workability. Unlike casting’s reliance on metal flow in liquid state, forging applies intense pressure to physically deform and shape the metal. This pressure comes through either hammering operations or powerful presses that can exert thousands of tons of force.

In investment casting, liquid metal cools and solidifies inside a stationary mold, with the material’s atomic structure forming naturally as temperature decreases. This crystallization process creates a relatively random internal grain structure.

Forging, by contrast, physically reshapes solid metal through intense pressure. This mechanical working doesn’t just change the external shape—it transforms the internal structure, breaking down and realigning the metal’s grain patterns. This forcible rearrangement compacts the material and creates aligned grain flow patterns that follow the part’s contours, much like wood grain follows the shape of a tree.

Investment casting demonstrates exceptional versatility, compatible with virtually all castable ferrous and non-ferrous metals and alloys. This includes aluminum, copper, steel, stainless steel, tool steel, and even high-performance superalloys used in aerospace applications.

Forging’s material range is comparatively limited by the requirement for sufficient ductility and the ability to withstand significant plastic deformation without fracturing, particularly at the selected forging temperature. Metals that become brittle or work-harden too quickly typically prove unsuitable for forging operations. Nevertheless, many common engineering metals—including carbon steels, alloy steels, stainless steels, aluminum alloys, titanium, and certain copper alloys—respond well to forging processes.

Investment cast parts feature an equiaxed grain structure, meaning the material’s crystals grow in roughly equal dimensions in all directions as the molten metal cools.

Forged parts develop a fibrous grain structure that resembles the grain in wood, flowing along the contours of the part. This directional alignment occurs as the metal deforms under pressure, with grains elongating and following the direction of metal flow.

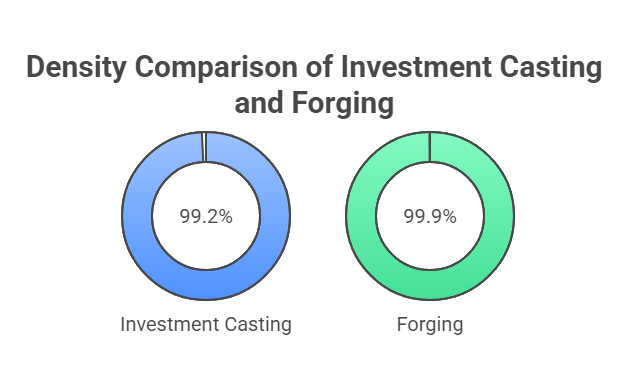

The Cornell University Materials Science Department conducted comparative studies showing cast components typically contain microscopic voids where gas bubbles formed during solidification. These voids, though small, create stress concentration points that can initiate cracks under load. Their research revealed that investment casting can achieve approximately 99.2% theoretical density.

Forging’s intense pressure eliminates these voids, compacting the material to achieve approximately 99.9% of theoretical density, according to the Forging Industry Association. The process also helps break up and disperse inclusions, resulting in denser, more homogeneous, and structurally sounder components with fewer defects.

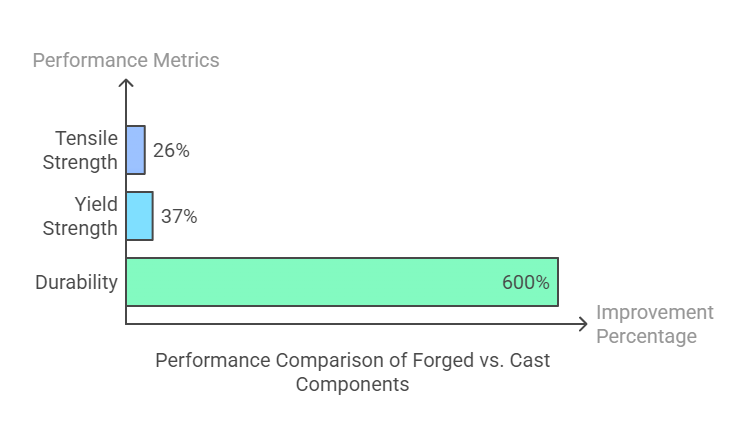

Forgings consistently deliver 26% higher tensile strength than equivalent castings of the same alloy. Yield strength—the point at which material begins to permanently deform—showed even greater improvement, with forged components demonstrating 37% higher values than cast alternatives.

The most dramatic difference appears in fatigue testing, where components undergo repeated cyclic loading. SAE International testing protocols revealed forged steel components survived approximately six times longer than cast equivalents under identical cyclic loading conditions.

Forgings possess higher toughness, enabling them to absorb more energy and handle impacts better than castings. They also typically exhibit superior ductility, allowing more deformation before fracture occurs.

Forging can strategically optimize strength along grain flow directions, which designers can align with primary stress paths in the component.

Casting characteristics derive from more random grain structures, tending toward isotropy (uniformity in all directions).

| Property | Investment Casting | Forging | Notes/References |

| Tensile Strength | Lower | Higher (e.g., ~26% higher) | Forged strength due to refined, wrought structure |

| Yield Strength | Lower | Higher (e.g., ~37% higher, or cast iron 66% of forged steel) | Indicates higher load capacity before permanent deformation |

| Fatigue Strength/Life | Lower | Significantly Higher (e.g., ~37% higher strength, 6x longer life) | Critical for cyclic loading; forging closes defects, aligns grains |

| Ductility (% Elongation/RA) | Lower (e.g., 6% RA) | Higher (e.g., 58% RA) | Forging enhances toughness and resistance to brittle fracture |

| Impact Resistance | Lower | Higher | Forged toughness beneficial under shock loads |

| Grain Structure | Typically Equiaxed, Random Orientation (Isotropic) | Refined, Wrought, Aligned with Flow (Anisotropic) | Fundamental difference driving property variations |

| Typical Integrity Issues | Porosity (Shrinkage, Gas), Inclusions, Hot Tears | Generally Sound, Voids Closed; Potential for Surface Scale, Die Wear | Forging process inherently consolidates material; Casting requires control of solidification defects |

| Heat Treatment Response | Good, but can be non-uniform due to segregation | Excellent, Predictable | Forging’s uniform structure ensures consistent response |

Investment casting excels at producing complex geometries that would be impossible or prohibitively expensive through other manufacturing methods. The ceramic shell can form around intricate wax patterns with internal passages, thin walls, and fine details.

Forging faces more significant geometric limitations. The need for metal to flow under compression while maintaining die contact typically restricts forging to simpler shapes. Undercuts, hollow sections, and extremely thin features generally prove difficult or impossible without secondary operations. Parts requiring such features often need machining after forging.

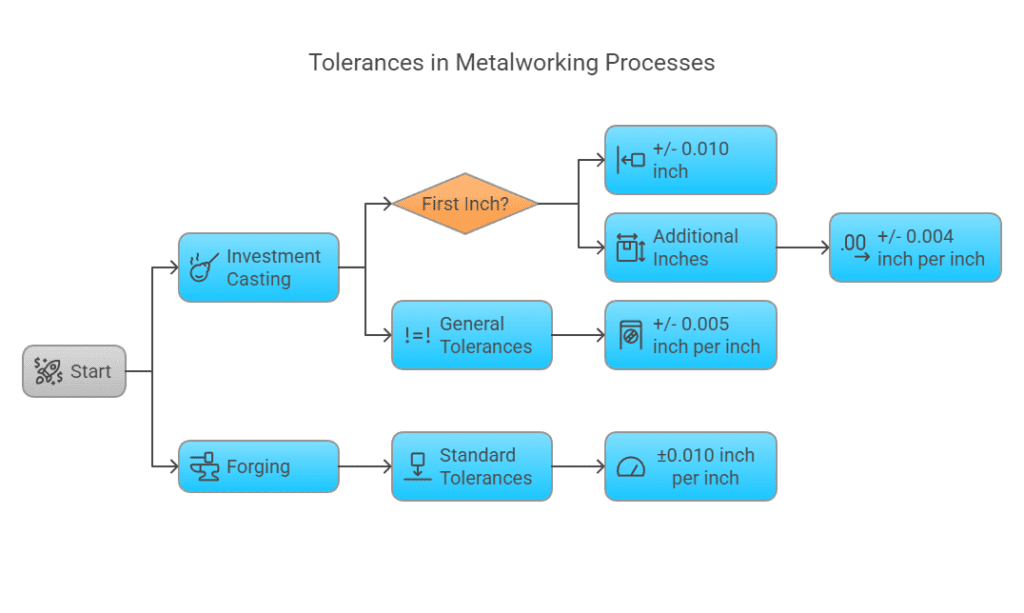

Investment casting delivers tight dimensional tolerances directly from the process, minimizing or sometimes eliminating the need for subsequent machining operations. Typical tolerance standards include +/- 0.010 inch for the first inch with +/- 0.004 inch for each additional inch, or general tolerances of +/- 0.005 inch per inch. This precision makes investment casting particularly valuable for components requiring high dimensional accuracy.

Forging typically produces less precise dimensions, with standard tolerances around ±0.010 inches per inch or more, depending on the specific process and equipment. This means most forged components require additional machining to achieve final dimensional specifications, adding production steps and costs.

Investment casting delivers excellent, smooth as-cast surface finishes. Typical surface roughness values measure around 125 Ra (microinches) and can achieve even finer finishes with specialized techniques.

Forging typically produces rougher surface finishes(between 250-500 Ra) compared to investment casting. The direct metal-to-die contact, oxide formation during heating, and die wear all contribute to surface texture issues that often necessitate additional finishing operations to achieve desired surface quality.

| Capability | Investment Casting | Forging (Open Die) | Forging (Closed Die) | Notes/References |

|---|---|---|---|---|

| Geometric Complexity (Intricacy, Internal) | Very High (Thin walls, internal passages, fine details) | Low (Simple shapes: bars, rings, discs) | Moderate to High (External detail possible, internal features limited) | Investment casting excels due to liquid metal fill; Forging limited by solid flow |

| Typical Dimensional Tolerance | Tight (e.g., ±0.005″/inch or ±0.010″ + 0.004″/inch) | Loose (Machining almost always required) | Moderate to Tight (Near-net possible, but often needs machining) | Investment casting is a “precision” process; Closed-die forging better than open-die, but often less precise than investment casting |

| Typical Surface Finish (As-Produced) | Excellent / Smooth (e.g., 125 Ra µin or better) | Rough | Good (Better than open-die, rougher than investment casting) | Ceramic mold yields smooth finish; Forging finish depends on die quality and scale |

| Parting Line Present? | No | No | Yes (Flash line) | Investment casting uses seamless shell; Closed-die forging has parting line where flash forms |

| Draft Angle Required? | Generally No | Generally No | Yes (Typically larger than casting) | Needed for part removal from rigid dies |

Both investment casting and forging require significant upfront tooling investments, but important differences exist:

Investment casting tooling is generally less expensive than the robust dies required for closed-die forging, particularly when dealing with complex part geometries or lower production volumes. The wax patterns used in investment casting can be produced from relatively inexpensive molds, while forging dies must withstand extreme forces and temperatures.

For you Choosing:

| Factor | Investment Casting | Forging (Closed Die) | Notes/References |

| Typical Tooling Cost (Relative) | Low to Moderate (Die-less option via 3D print) | Very High | Forging dies are robust & expensive; IC tooling often cheaper, esp. for complex parts or low vol |

| Material Utilization / Waste | Good to Excellent (Near-net shape, recycled gates) | Good (Reshaping, not cutting; Flash is waste) | Both better than machining; IC minimizes machining waste; Forging flash is waste |

| Suitability for Low Volume | Good (Especially with 3D printed patterns) | Poor (Due to high tooling cost) | IC tooling flexibility favors low vol; Forging tooling cost prohibitive for short runs (Open-die is exception for simple shapes) |

| Suitability for High Volume | Good (Automation dependent) | Excellent (Tooling cost amortized) | Forging excels at high vol. due to speed once tooled; IC can be competitive, esp. if machining is avoided |

| Need for Secondary Machining (Typ.) | Minimal to None | Often Required (More than IC) | IC’s near-net shape is key advantage; Forging often needs finish machining for tolerance/finish |

| Overall Cost Driver | Process complexity, Labor (if manual), Reduced Machining Cost | High Tooling Cost (amortization), Raw Material, Machining Cost | Total cost depends on balancing tooling, volume, complexity, material, and downstream processing |