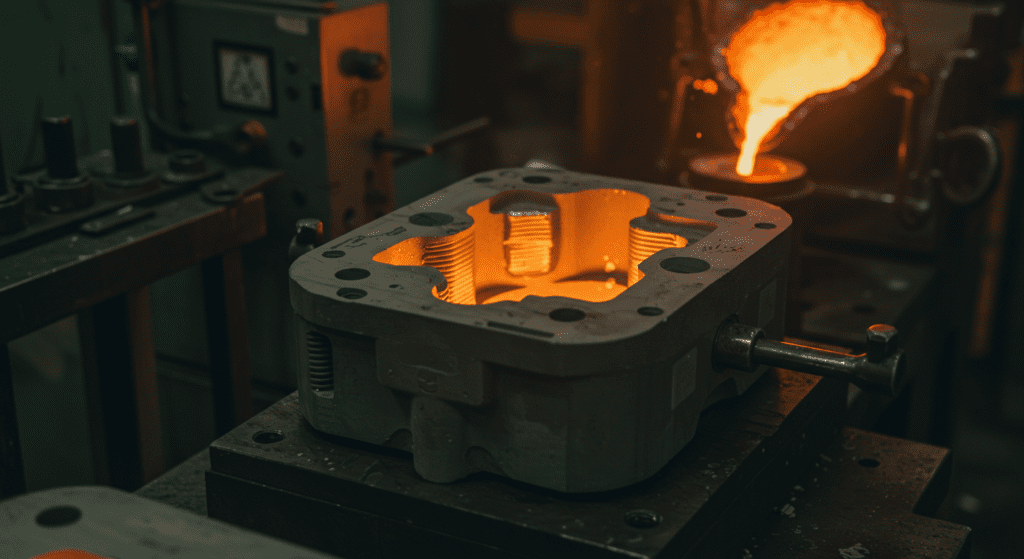

At their core, lost-wax casting and investment casting describe the same manufacturing method. The foundational process is identical: a sacrificial pattern, typically made of wax, is created in the exact shape of the desired object. This pattern is then coated with a refractory material, which hardens to form a one-piece, seamless mold. The mold is subsequently heated to melt out, or “lose,” the wax, leaving a precisely detailed cavity. Molten metal is then poured into this cavity. Once the metal solidifies, the mold is destroyed to retrieve the final casting. Because the pattern is sacrificed, a new one must be created for every single part produced.

This is the older and more descriptive term, derived directly from the French cire perdue. It focuses on the fate of the pattern: it is “lost” or destroyed during the creation of the mold cavity. This name emphasizes the sacrificial nature of the pattern, a defining characteristic of the process since antiquity. It speaks to the transformation of a temporary wax model into a permanent metal object.

This term gained prominence as the process was industrialized in the mid-20th century. Its origin lies in the Latin verb ‘investire’, which means “to clothe” or “to surround”. The name refers specifically to the mold-making step, where the wax pattern is “invested” or “clothed” in a ceramic slurry. This terminology reflects a modern engineering focus on the mold itself—the “investment”—as the critical tool that imparts precision, detail, and dimensional accuracy to the final component. The name shifts the focus from the destruction of the pattern to the creation of the high-performance mold.

| Feature | Lost-Wax Casting (Artisanal/Historical Context) | Investment Casting (Modern Industrial Context) |

|---|---|---|

| Primary Application | Fine art, unique sculptures, custom jewelry, decorative objects | Functional engineering components for aerospace, automotive, medical, defense, and power generation industries |

| Core Focus | Aesthetic fidelity, capturing intricate artistic detail, one-of-a-kind creation | Dimensional accuracy, achieving tight tolerances, ensuring mechanical performance, and high-volume repeatability |

| Pattern Creation | Primarily manual hand-carving or sculpting of patterns from materials like beeswax or clay, emphasizing artistic skill | Highly automated process using injection-molded, engineered wax patterns from durable metal dies; or 3D-printed patterns for rapid prototyping and extreme complexity |

| Mold Material | Historically, simple clay or plaster-silica mixtures | Engineered, multi-layer ceramic shells made from advanced refractory materials like silica, zircon, and alumina with specialized binders |

| Alloys Cast | Traditional artistic and precious metals: bronze, gold, silver, brass | Vast range of ferrous and non-ferrous alloys: stainless steels, carbon steels, aluminum, titanium, and high-performance superalloys |

| Production Volume | Single piece or very small, limited-edition batches | Medium to high-volume production, casting hundreds of identical parts simultaneously on a “tree” assembly |

| Dominant Terminology | Cire Perdue, Lost-Wax Casting | Investment Casting, Precision Casting |