Here’s a fact that surprises most people: true wrought iron hasn’t been commercially produced since 1973. The last plant in the world – the Atlas Forge in Bolton, England – closed its doors over 50 years ago. That decorative fence or garden gate labeled “wrought iron” at your local home improvement store? It’s almost certainly mild steel.

This matters because choosing between wrought iron, cast iron, and their modern substitutes depends on understanding what each material actually is – and what it can do for your project. By the end of this guide, you’ll know exactly which material fits your needs.

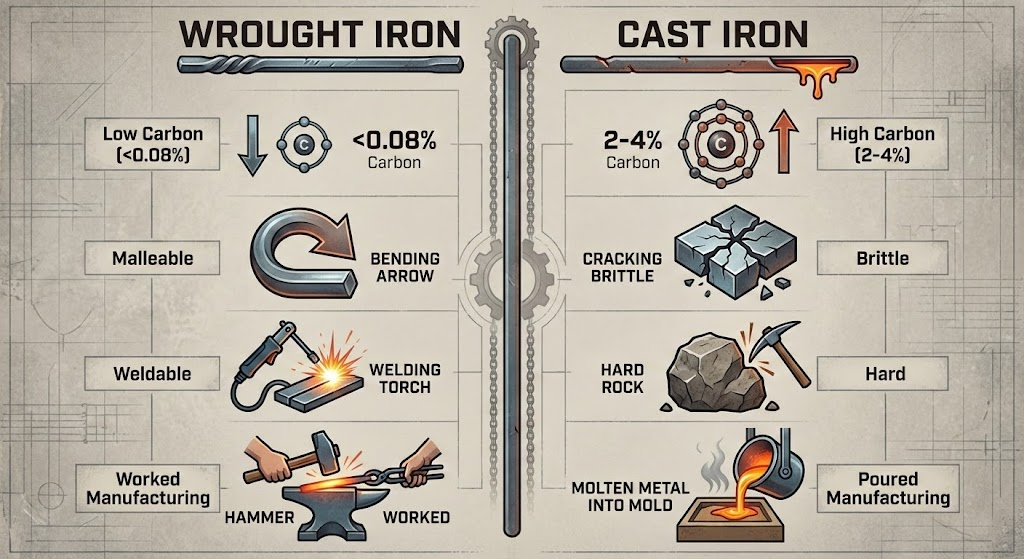

Carbon content is the fundamental difference between these two materials. Wrought iron contains less than 0.08% carbon, while cast iron contains 2 to 4% carbon. This single difference in composition explains almost every other property that sets them apart.

The word “wrought” is the past participle of “work” – it literally means “worked iron.” Blacksmiths heat wrought iron and shape it by hammering, bending, and twisting. The material is soft enough to manipulate and grows stronger the more you work it.

Cast iron takes the opposite approach. Foundries melt the iron, pour it into molds, and let it solidify. Once cooled, the shape is fixed. You cannot bend, stretch, or hammer cast iron into a new form without breaking it.

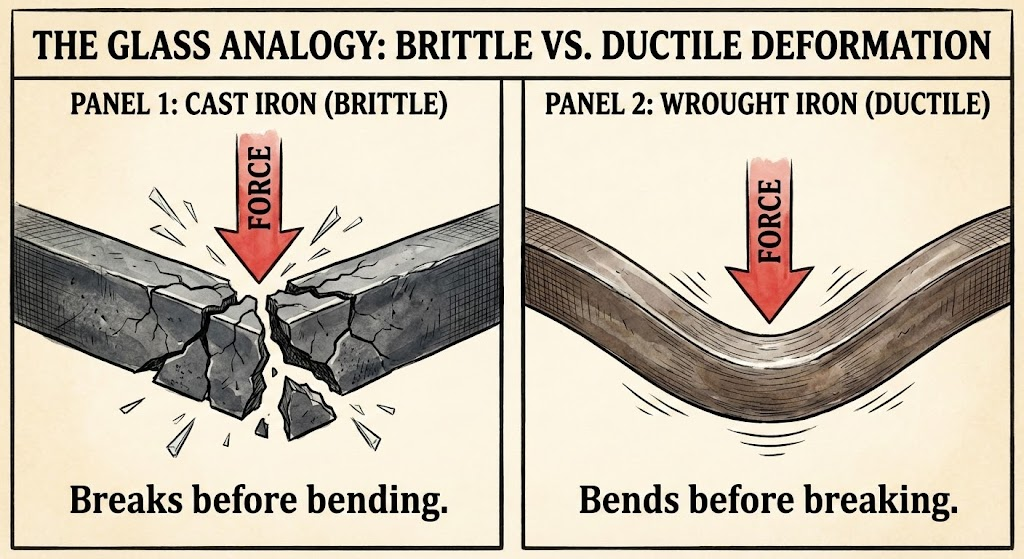

The more carbon present in a material, the more brittle it becomes. This is why wrought iron can be reshaped repeatedly while cast iron cracks under similar treatment. If you remember just one thing from this article, remember this: low carbon means malleable, high carbon means brittle.

Wrought iron production ended because it couldn’t compete economically with modern steel. The last U.S. wrought iron plant closed in 1969, and the final worldwide producer shut down in 1973.

Producing wrought iron costs approximately twice as much as making low-carbon steel. When mild steel offers similar properties – low carbon content, good malleability, excellent weldability – manufacturers had no reason to continue the more expensive process.

As one industry source puts it: “Anything you see today that resembles wrought iron is usually mild steel, unless it is more than 100 years old.” That antique gate from a Victorian estate might be genuine wrought iron. The new one from a fabricator is almost certainly mild steel.

I recommend against paying a premium for products marketed as “wrought iron.” Modern mild steel performs nearly identically for decorative applications, and the term has become more of a style description than a material specification.

The answer depends entirely on what type of strength your application requires. Wrought iron wins for tensile strength (resistance to pulling and stretching), with ratings between 240 and 350 MPa. Cast iron wins for compressive strength – resistance to crushing forces.

Think of cast iron like glass: strong but brittle. As welding specialists describe it, cast iron “will break before it bends.” Drop a cast iron pan and it might crack. Try to bend cast iron and it shatters rather than flexing.

Wrought iron behaves oppositely. It deforms under stress instead of fracturing, and repeated heating and working actually increases its strength. This property made it invaluable for everything from ship anchors to railroad bridges before steel became dominant.

For any application where impact, vibration, or future modification might occur, I suggest avoiding cast iron. Its brittleness becomes a liability when environments are unpredictable or when repairs might be needed later.

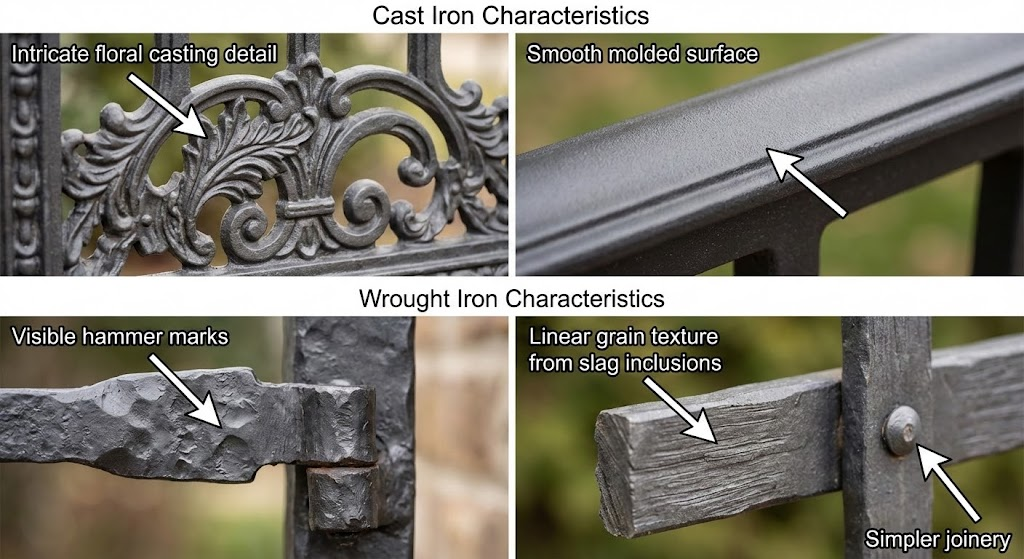

Identifying these materials requires examining both visual characteristics and physical properties. Each material leaves distinct clues.

Design complexity offers the first clue. Cast iron excels at capturing intricate details, so historically it was used for ornate, naturalistic motifs – think flowers, leaves, and elaborate scrollwork. Manufacturers could pour liquid iron into detailed molds and reproduce the same complex design thousands of times.

Wrought iron pieces show simpler, more geometric patterns. Scrolls, straight bars, twisted elements, and basic curves are common because blacksmiths shaped each piece by hand. The labor required to create complex designs in wrought iron made such pieces expensive and rare.

Surface texture provides another indicator. Polished wrought iron reveals a linear, grain-like appearance caused by slag inclusions running through the metal – the result of its 1 to 2% slag content.

The most definitive test involves attempting to bend the material. Wrought iron flexes; cast iron cracks. If a piece has survived decades of use without fracturing despite impacts and stress, it’s likely wrought iron or mild steel.

Historic ironwork that pre-dates 1900 and shows signs of hand forging (hammer marks, slight irregularities, simple joinery) is probably genuine wrought iron. Anything manufactured after the mid-20th century with cast-in details is almost certainly cast iron or mild steel, depending on the complexity.

Age remains the most reliable indicator. If the piece is less than 50 years old, assume it’s either cast iron (for complex decorative items) or mild steel (for simpler structural pieces).

Each material suits specific applications based on its properties. Choosing correctly means matching the material to your project’s requirements.

| Application | Best Material | Key Reason |

|---|---|---|

| Decorative gates and fences | Mild steel | Workable, repairable, readily available |

| Complex decorative castings | Cast iron | Captures intricate mold details economically |

| Cookware and skillets | Cast iron | Superior heat retention, develops non-stick seasoning |

| Engine blocks | Grey cast iron | Excellent vibration damping, thermal stability |

| Pipes and plumbing fittings | Cast iron or ductile iron | Compression strength, corrosion resistance |

| Items requiring future repair | Mild steel | Can be re-welded, cut, and reshaped |

Grey iron vs ductile iron represents an important distinction within the cast iron family. Ductile iron can resist a minimum of 7 foot-pounds of impact compared to just 2 foot-pounds for grey iron, making it better suited for applications where shock loads occur.

For most homeowners selecting outdoor ironwork, mild steel is the practical default. It’s affordable, widely available, and any welder can repair it. Reserve cast iron for situations where its specific advantages – complex shapes, heat retention, or compression strength – genuinely matter.

Material costs vary significantly by region and application, but understanding relative pricing helps with budgeting.

True wrought iron, when available as architectural salvage, commands a 20 to 50% premium over comparable mild steel pieces. The scarcity drives prices higher since no new production exists.

For new fabrication, mild steel gates typically cost around $100 less than equivalent cast iron designs for comparable sizes. The savings come from easier manufacturing and lower material costs.

Repair costs for existing ironwork follow predictable patterns. Fence repair runs $30 to $50 per linear foot on average. Railing repairs range from $75 to $1,000, with most projects falling around $500. Gate repairs cost $100 to $400 per gate.

For those considering custom iron castings, grey iron casting costs approximately $1 to $2 per pound for net snagged castings at U.S. foundries. The total project cost depends on pattern complexity, quantity, and finishing requirements.

Factor long-term maintenance into your decision, not just purchase price. Cast iron’s brittleness can mean higher repair costs when pieces crack, while mild steel’s weldability makes repairs straightforward.

Both materials require protective coatings for outdoor durability, but they differ in natural corrosion resistance.

Wrought iron historically showed better rust resistance than cast iron. The siliceous slag inclusions within the metal created a barrier that slowed oxidation. This explains why some wrought iron pieces from the 1800s still function today while cast iron from the same era has corroded beyond repair.

Cast iron’s higher carbon content and more porous structure make it more susceptible to rust. Without proper protection through paint, powder coating, or galvanizing, cast iron deteriorates more quickly in humid or wet environments.

Maintenance costs reflect this difference. Cleaning and removing rust from decorative ironwork costs $7 to $10 per linear foot. Cast iron typically requires more frequent maintenance cycles than wrought iron or mild steel.

For outdoor applications in challenging environments, mild steel with quality powder coating represents the most practical solution. It combines good corrosion resistance with easy repairability and reasonable cost. When properly maintained, modern coated mild steel outlasts poorly maintained cast iron despite the latter’s potentially longer theoretical lifespan.

Selecting between these materials comes down to answering five key questions about your project requirements.

Will you need to modify or repair the piece later? If yes, choose mild steel. Its weldability and malleability make future changes possible. Cast iron welding requires special techniques and may still crack, making modifications risky.

Does your design require complex decorative shapes? Cast iron captures intricate details economically through the molding process. Achieving similar complexity in forged work costs substantially more.

Will the piece experience impacts or sudden loads? Avoid cast iron for these applications. In colder environments or under unexpected loads, brittle cast iron may crack suddenly. Mild steel and wrought iron absorb energy by deforming rather than fracturing.

Are high compression loads the primary stress? Cast iron excels here. Its hardness – approximately 86 Rockwell, comparable to stainless steel – makes it ideal for components like machine bases that must resist crushing forces.

Is budget a primary concern? Mild steel offers the best value for most decorative and structural applications. It’s readily available, easy to work, and costs less than genuine wrought iron or custom cast iron.

The fundamental question underlying all these considerations is whether you need workability (choose mild steel) or shape complexity (choose cast iron). Most projects benefit from mild steel’s forgiveness, especially for those new to working with iron materials.

Ready to move forward with your iron project? For custom cast iron components – decorative reproductions, industrial parts, or specialized castings – working with an experienced foundry ensures you get the right material specification and quality for your application.