Cast steel and forged steel are two distinct manufacturing methods that produce steel components with different properties and characteristics. Cast steel is made by pouring molten steel into molds, while forged steel is shaped by applying compressive forces to heated steel. Each process creates unique grain structures, mechanical properties, and cost considerations that make them suitable for different applications.

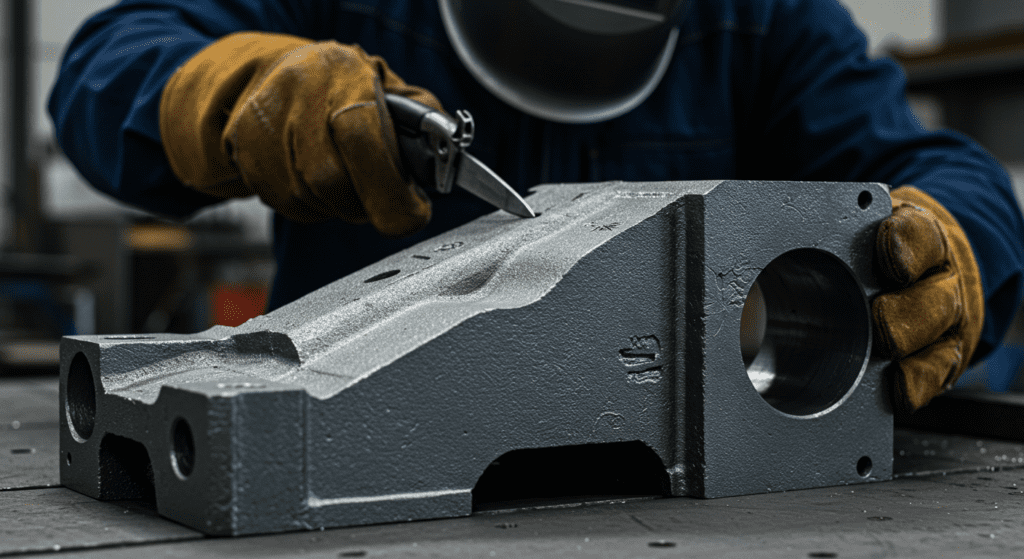

Cast steel is steel that has been melted and poured into a mold to create a specific shape. The process involves heating steel to temperatures above 2,500°F until it becomes liquid, then pouring it into prepared molds where it cools and solidifies. This method produces complex shapes that would be difficult or impossible to create through other manufacturing processes.

The material consists of iron with 0.1% to 0.5% carbon content, along with other alloying elements like manganese, silicon, and chromium. Cast steel parts are found in heavy machinery, automotive components, and industrial equipment. The process creates parts with good wear resistance and the ability to handle moderate stress loads.

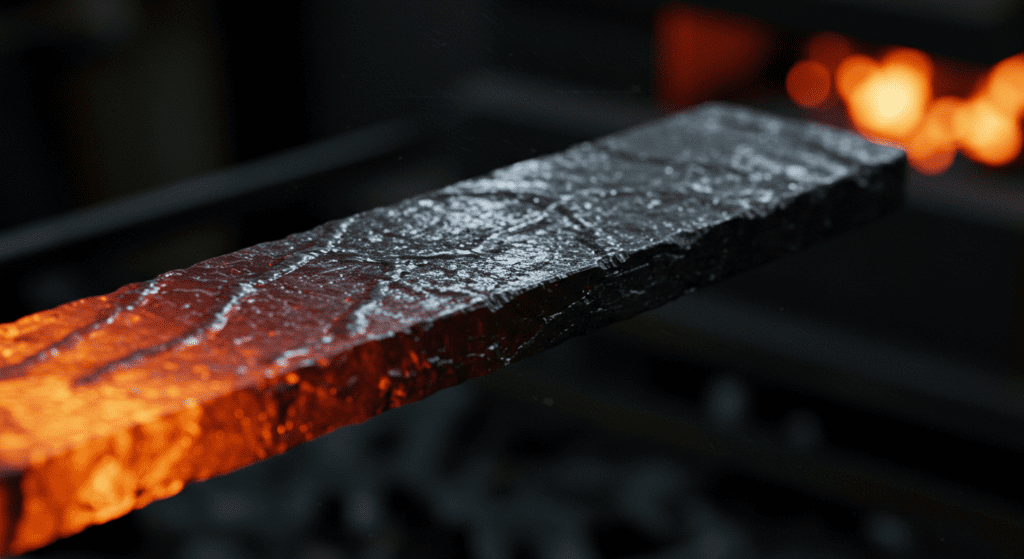

Forged steel is steel that has been shaped through the application of compressive force while the metal is hot. The process involves heating steel billets to 2,100°F to 2,300°F and then hammering or pressing them into the desired shape. This mechanical working refines the grain structure and improves the steel’s strength and toughness.

The process creates parts with directional strength characteristics aligned with the component’s shape. Forged steel exhibits superior mechanical properties compared to cast steel, including 26% higher tensile strength and 37% greater fatigue resistance. Common forged products include crankshafts, connecting rods, gears, and hand tools.

| Property | Cast Steel | Forged Steel |

|---|---|---|

| Grain Structure | Random, coarse grains with potential voids | Fine, directional grains following part contours |

| Tensile Strength | 65,000-80,000 psi for carbon steel | 82,000-110,000 psi for same grade |

| Yield Strength | 35,000-50,000 psi typical | 50,000-80,000 psi typical |

| Ductility | 18-25% elongation | 20-30% elongation |

| Impact Resistance | 20-40 ft-lbs at room temperature | 35-60 ft-lbs at room temperature |

| Fatigue Life | Lower due to internal defects | 37% higher due to refined structure |

| Part Complexity | Handles intricate shapes and internal passages | Limited to simpler external geometries |

| Size Range | From ounces to 400,000 pounds | From ounces to 50,000 pounds |

| Surface Finish | Rough, requires extensive machining | Smoother, needs less finishing |

| Typical Applications | Valve bodies, pump housings, engine blocks, machinery frames | Crankshafts, connecting rods, axles, high-stress components |

| Production Volume | Economical for 1-10,000 pieces | Best for 100-1,000,000 pieces |

| Tooling Cost | $5,000-50,000 for sand casting patterns | $20,000-500,000 for forging dies |

| Lead Time | 4-8 weeks typical | 8-16 weeks for new tooling |

| Material Utilization | 60-80% yield from raw material | 80-95% yield with less waste |

| Cost per Pound | $2-5 for simple shapes | $3-8 depending on complexity |

| Design Flexibility | Accommodates undercuts and varying wall thickness | Requires draft angles and uniform sections |

| Quality Consistency | Moderate, with potential for porosity | High, with predictable properties |

| Weldability | Good, but requires careful procedures | Excellent with proper preparation |

| Machinability | Varies with internal soundness | Consistent and predictable |