The yield point is the stress level where a metal starts to permanently deform. Below this stress, the metal behaves like a spring – it bends but bounces back to its original shape when you release the force. Above the yield point, the metal stays bent even after you remove the load.

Engineers use the yield point as a critical safety threshold. They design structures so that normal operating stresses stay well below this point, ensuring buildings don’t permanently sag, car parts don’t deform, and bridges maintain their shape over decades of use.

Some metals, especially mild steel, show two distinct yield points instead of just one. The upper yield point is a brief stress peak where the metal first starts to yield. Immediately after, the stress drops to a lower yield point where plastic deformation continues at a constant, lower stress.

This happens because of how atoms interact inside the metal. Carbon and nitrogen atoms in steel act like tiny anchors that pin the metal’s internal structure in place. Breaking these anchors requires extra force – that’s the upper yield point.

Once these anchors break free, the metal flows more easily at the lower yield point. You can actually see this happening as visible bands called Lüders bands that spread across the metal surface during testing.

Engineers typically use the lower yield point for design calculations since it represents the sustained stress level during plastic flow. Materials like aluminum alloys don’t show this two-step behavior – they yield gradually instead.

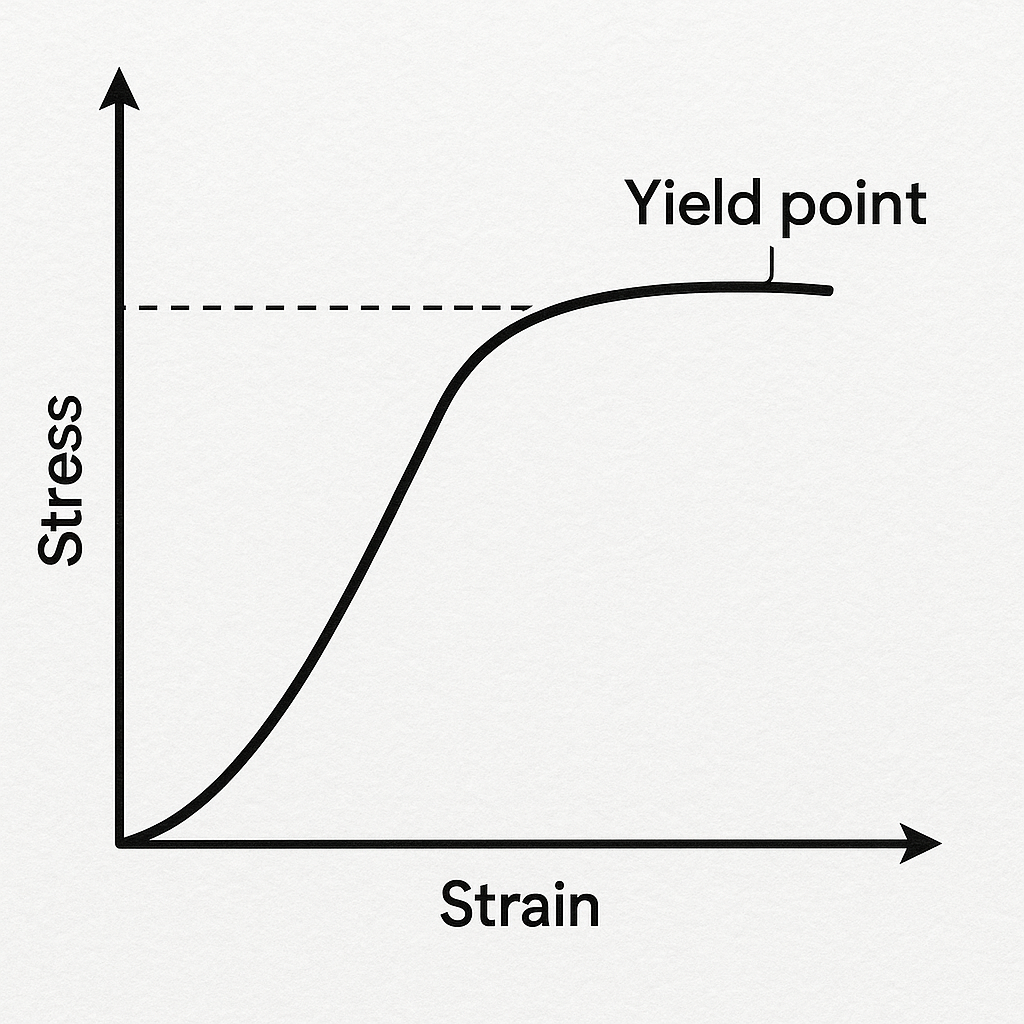

The yield point is measured using a tensile test where a metal sample is pulled apart at a controlled rate. A machine records both the applied force and how much the sample stretches, creating a stress-strain curve that shows exactly where yielding begins.

For metals with a clear yield point like mild steel, you’ll see a sudden drop or “knee” in the curve. But many metals transition gradually from elastic to plastic behavior, making the exact yield point harder to spot.

When there’s no sharp yield point, engineers use the 0.2% offset method. They draw a line parallel to the elastic portion of the curve, offset by 0.2% strain. Where this line intersects the actual curve defines the yield strength – representing the stress that causes a tiny but permanent 0.2% deformation.

Several key factors determine a metal’s yield strength:

| Material | Yield Strength (MPa) |

|---|---|

| Low-carbon steel (ASTM A36) | ~250 MPa |

| High-strength alloy steel (A514) | ~690 MPa |

| Aluminum alloy (6061-T6) | ~240 MPa |

| Copper (99.9% pure, annealed) | ~70 MPa |

| Titanium alloy (Ti-6Al-4V, Grade5) | ~830 MPa |

Yield strength marks when permanent deformation begins, while tensile strength is the maximum stress before the material breaks. A metal yields first, continues to deform while getting stronger (work hardening), then eventually fractures at its tensile strength.

Yes, factors like fatigue loading, corrosion, and temperature exposure can alter yield strength. Cold work during service can increase it, while high temperatures or stress corrosion can decrease it significantly.